Sheet forming die and method of helical cylinder gear

A technology of helical cylindrical gears and forming molds, applied in the directions of gears, forming tools, household appliances, etc., can solve the problems of short gear life, low material utilization, difficult corner filling, etc., to avoid large forming force and reduce production. cost, the effect of improving end face quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and examples, but of course the following examples should not be construed as limiting the present invention.

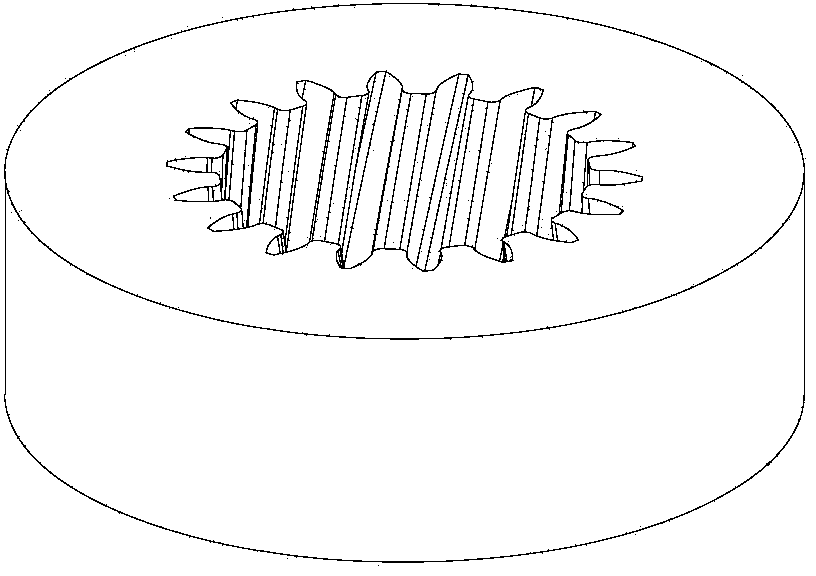

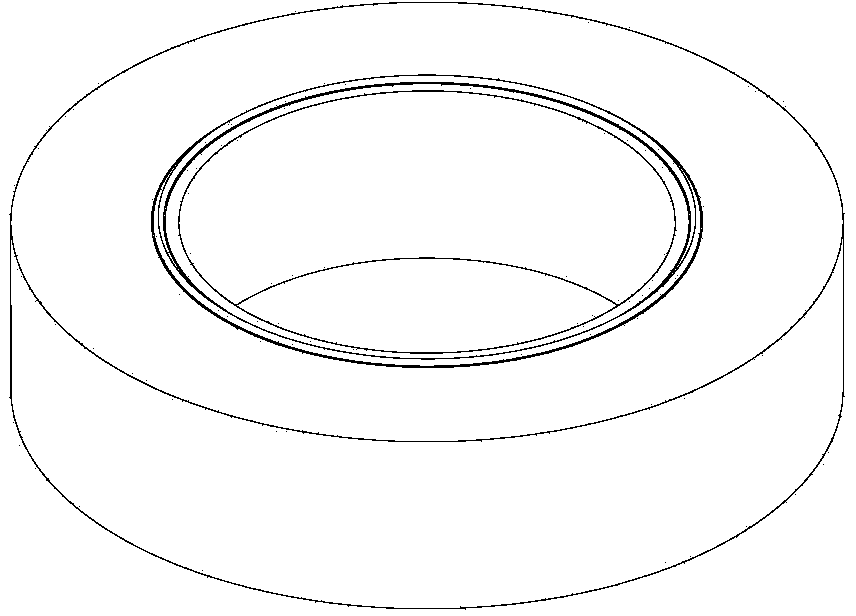

[0034] Such as Figure 1 to Figure 8 As shown, it is a sheet metal forming die for a helical spur gear provided in an embodiment of the present invention. The sheet material forming die of the helical cylindrical gear includes a sheet material cold precision die assembly and a rotary blanking die assembly. The plate cold precision mold assembly includes a first punch 1 , a first die 4 , a V-ring blank holder 2 , and an anti-top plate 5 . The rotary blanking die assembly includes a second punch 6 and a second die 8 . The first punch 1 is a smooth cylinder, and the inner wall of the V-ring blank holder 2 matches the outer wall of the first punch 1 . The inner wall of the first die 4 and the outer wall of the anti-top plate 5 are provided with helical teeth. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com