A manufacturing process of anti-scalding ceramic silver-inlaid utensils

A production process and utensil technology, which is applied in the field of production technology of anti-scalding ceramic silver-inlaid utensils, can solve the problems of poor practicability, easy scalding of hands and lips, easy scalding of skin, etc. heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiment of the present invention is a manufacturing process of anti-scald ceramic silver-inlaid utensils. The anti-scald ceramic silver-inlaid utensils are anti-scald ceramic silver-inlaid bowls, anti-scald ceramic silver-inlaid cups and other anti-scald ceramic silver-inlaid living utensils. The technical solution of the present invention will be further described below through the manufacturing process of the anti-scald ceramic silver inlaid bowl.

[0023] like figure 1 , 2 , Shown in 3 and 4, a kind of manufacturing process of anti-scalding ceramic silver inlaid bowl comprises the following steps:

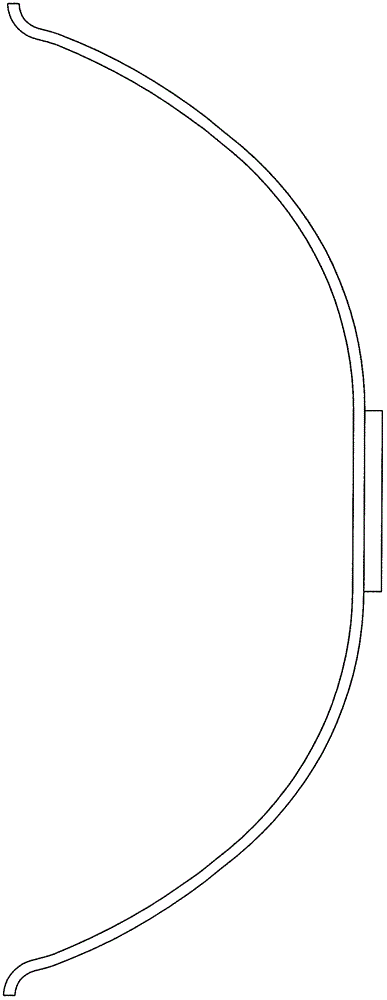

[0024] (1) embryo making: such as figure 1 As shown, through four steps of raw material processing, making mud embryo, molding and firing, the ceramic bowl blank is made;

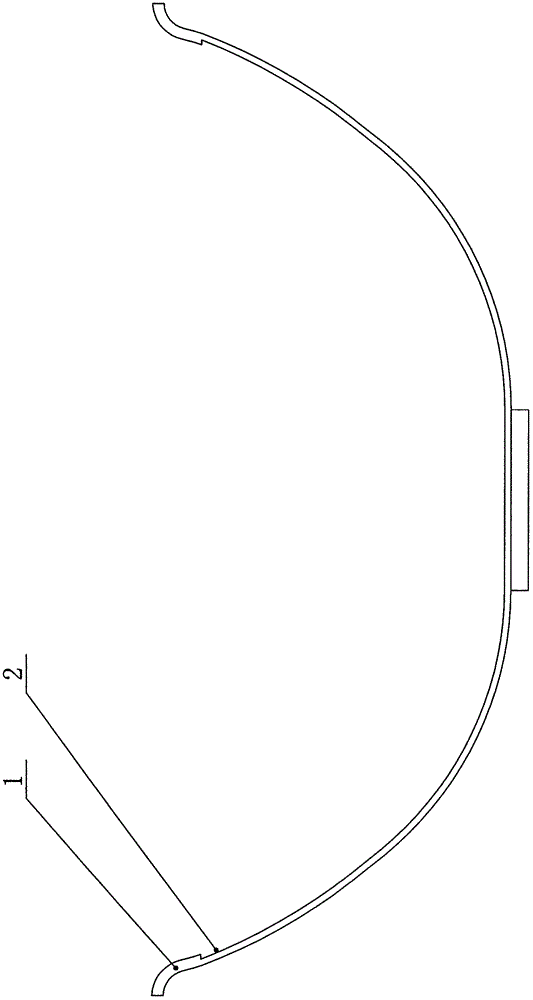

[0025] (2) Grooving: such as figure 2 As shown, a semi-spherical liner tank body is carved on the inner wall of the ceramic bowl blank obtained in step (1) with a Jingdiao machine, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com