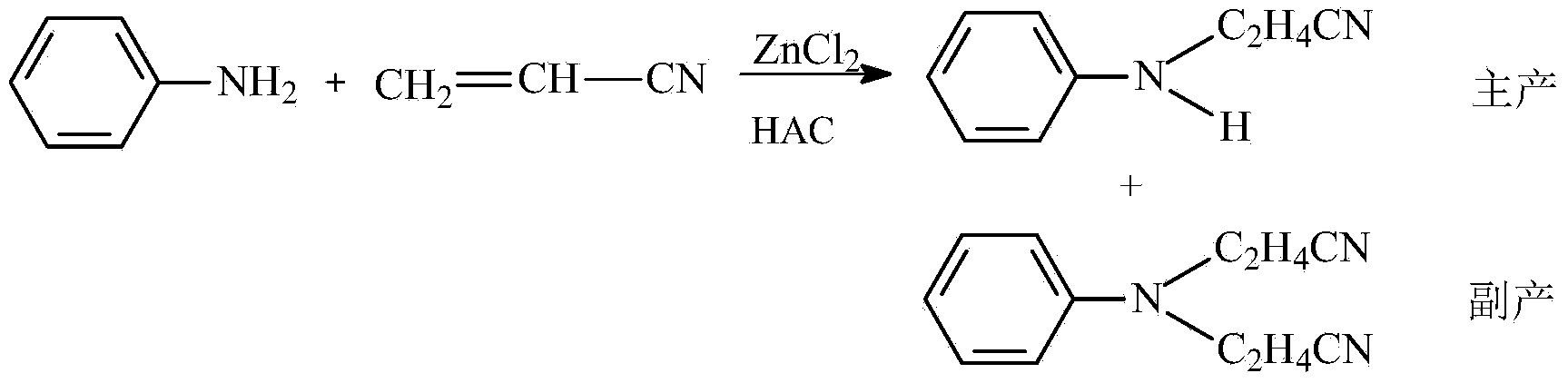

Method for producing N-cyanoethylaniline and N,N-dicyanoethylaniline by adopting one-step cleaning process

A technology for dicyanoethylaniline and cyanoethylaniline is applied in the field of producing N-cyanoethylaniline and N.N-dicyanoethylaniline by a one-step cleaning process, and can solve the problems of multiplying production cost, measurement error, production The problem of high cost is to achieve the effect of reducing the cost of three wastes treatment, simple process control and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 10,000 liters enamel reaction kettle with 30 square meters of sheet enamel condenser, after the inspection of the equipment, add 5000kg of aniline industrial products, 220kg of zinc chloride, 10kg of hydroquinone from the metering tank, seal the reaction kettle, open the condensed water and vacuum, and inhale ice Acetic acid 420kg, water 430kg, then add acrylonitrile 3420kg from the metering tank, slowly heat up, there is back distillation at 68-72 ℃, after back distillation for 2-3 hours, the temperature is at 90 ± 1 ℃, keep 90-100 ℃ back distillation for 10 -13 hours, sample the middle control until the middle control aniline is 0.1±0.02%, N.N-dicyanoethylaniline is 10±2%, and the sum of N-cyanoethylaniline and N.N-dicyanoethylaniline is greater than 98%.

[0028] After the end point, stand still for 2 hours, separate the water phase from the bottom, and then pump the organic phase into the middle tank (the temperature of the middle tank is higher than 60 ° C), and pum...

Embodiment 2

[0031] In the 10000 liter enamel kettle, add 4000kg of aniline, 800-1000kg of water phase, add 200kg of light components, add glacial acetic acid, water, and zinc chloride to the total amount of 176kg, 338kg and 344kg according to the calculation. Hydroquinone 8kg, acrylonitrile 2655kg, slowly heat up to 90±1°C for 2-3 hours, keep at 90-100°C, return distillation reaction for 10-13 hours, and control in the middle.

[0032] After the end point is reached, the organic phase is statically separated to the intermediate tank for rectification in a continuous distillation column (similar to Example 1), and the aqueous phase is about 800-1000kg in the next batch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com