A finishing method for improving the hand feeling of polyester-cotton interwoven jacquard transfer printing fabric

A transfer printing and fabric technology, applied in the field of dyeing and finishing, can solve the problems of not easy to wash off, good compatibility, short sublimation time at high temperature, etc., achieve good effect, improve water solubility, and improve color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

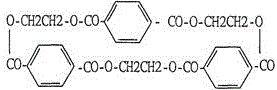

Image

Examples

Embodiment 1

[0021] Refining process:

[0022] Refining agent 7g.L

[0023] Degreaser 3g / L

[0024] Caustic soda 4g / L

[0025] Chelating dispersant 2g.L

[0026] Penetrant 1.5g / L

[0027] 100℃×60min

[0028] Bleaching process:

[0029] 27.5% hydrogen peroxide 6g / L

[0030] Caustic soda 2.5g / L

[0031] Stabilizer 2.5g / L

[0032] Whitening process:

[0033] Whitening agent DT

[0034] Penetrant JFC

[0035] 175℃×50s

[0036] Transfer printing:

[0037] Printing color paste: 7.5% by weight of disperse dye, 2.5% by weight of cationic dispersant, 25% by weight of paste, and the rest is water

[0038] Heat transfer temperature 180°C

[0039] Alkaline reduction cleaning process:

[0040] Ammonia (NH 3 )5g / L

[0041] Nonionic emulsifying and dispersing agent AEO-9 5g / L (Nantong Sangda Chemical Industry)

[0042] Oligomer dispersant ZETESAN OLE 3g / L; (Germany Sima Chemical Company)

[0043] 30℃×30min, washed twice with water

[0044] Soft setting process:

[0045] Softener for ...

Embodiment 2

[0049] Refining process:

[0050] Refining agent 6g.L

[0051] Degreaser 3g / L

[0052] Caustic soda 3g / L

[0053] Chelating dispersant 2g.L

[0054] Penetrant 1g / L

[0055] 100℃×60min

[0056] Bleaching process:

[0057] 27.5% hydrogen peroxide 5g / L

[0058] Caustic soda 2g / L

[0059] Stabilizer 2g / L

[0060] Whitening process:

[0061] Whitening agent DT

[0062] Penetrant JFC

[0063] 170℃×45s

[0064] Transfer printing:

[0065] Printing color paste: 7% by weight of disperse dye, 2% by weight of cationic dispersant, 20% by weight of paste, and the rest is water

[0066] Heat transfer temperature 175°C

[0067] Alkaline reduction cleaning process:

[0068] Ammonia (NH 3 ) 4g / L

[0069] Nonionic emulsifying and dispersing agent AEO-9 4g / L (Nantong Sangda Chemical Industry)

[0070] Oligomer dispersant ZETESAN OLE 2g / L; (Germany Sima Chemical Company)

[0071] 25℃×28min, wash twice with water

[0072] Soft setting process:

[0073] Softener for washing HS-...

Embodiment 3

[0077] Refining process:

[0078] Refining agent 8g.L

[0079] Degreaser 3g / L

[0080] Caustic soda 5g / L

[0081] Chelating dispersant 2g.L

[0082] Penetrant 2g / L

[0083] 100℃×60min

[0084] Bleaching process:

[0085] 27.5% hydrogen peroxide 7g / L

[0086] Caustic soda 3g / L

[0087] Stabilizer 3g / L

[0088] Whitening process:

[0089] Whitening agent DT

[0090] Penetrant JFC

[0091] 180℃×60s

[0092] Transfer printing:

[0093] Printing color paste: 8% by weight of disperse dye, 3% by weight of cationic dispersant, 30% by weight of paste, and the rest is water

[0094] Heat transfer temperature 185°C

[0095] Alkaline reduction cleaning process:

[0096] Ammonia (NH 3 )6g / L

[0097] Nonionic emulsifying and dispersing agent AEO-9 6g / L (Nantong Sangda Chemical Industry)

[0098] Oligomer dispersant ZETESAN OLE 5g / L; (Germany Sima Chemical Company)

[0099] 35℃×32min, washed twice with water

[0100] Soft setting process:

[0101] Softener for washing HS-0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com