Elastic joint structure

An elastic and structural technology, applied in the structural field of elastic joints, can solve the problems of unfavorable force, inability to work together, and affect the durability of buildings, so as to solve the joints that are easy to crack, solve common quality problems, and solve problems that are easy to crack Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

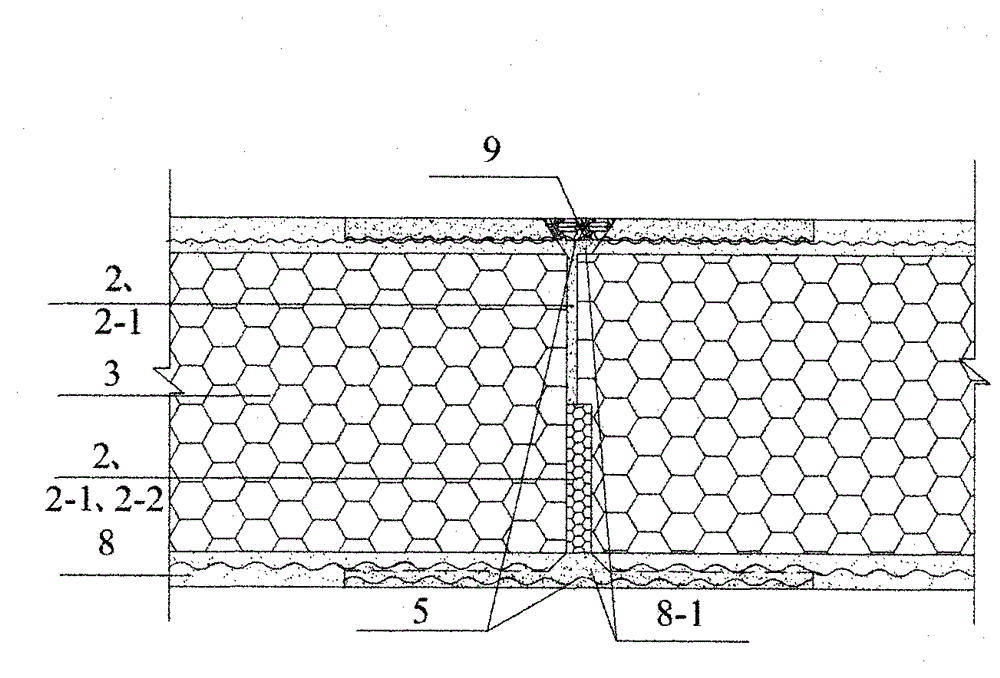

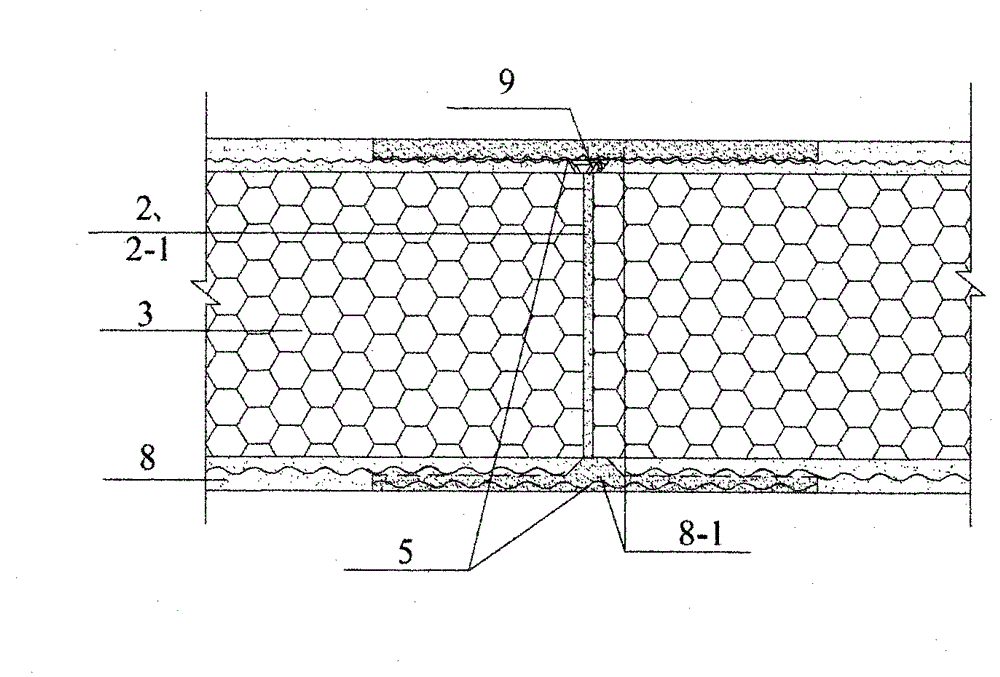

[0027] Implementation mode one: see Figure 1 ~ Figure 4 , an elastic joint structure of the present embodiment, which is composed of a prefabricated composite thermal insulation board 1 and an adhesive material 2 at the joint; The thermal insulation board 1 is adhesively connected, and the adhesive material 2 at the joint can transmit internal force, so that adjacent prefabricated composite thermal insulation panels form a common force-bearing member, and the adhesive material 2 at the joint also has the ability to adapt to a certain deformation (for example, in the The ability to deform under the action of temperature, and the ability to deform under the action of load), forming an elastic joint structure between prefabricated composite thermal insulation boards; the prefabricated composite thermal insulation board 1 is a prefabricated composite thermal insulation board of various structures.

[0028] The prefabricated composite thermal insulation board 1 is composed of a th...

Embodiment approach 2

[0030] Implementation mode two: see Figure 1 ~ Figure 4 , this embodiment provides the following elastic joint structure for reference, which is selected according to the design requirements of convenient construction and energy saving:

[0031] 1) The bonding material 2 at the joint is elastic bonding material 2-1 (such as bonding with cement polymer elastic mortar or cement polymer elastic thermal insulation mortar); or the joint is close to the side with intense temperature changes (usually the room The adhesive material 2 of the inner seam of a certain length on the outside is an elastic adhesive material 2-1, and the adhesive material 2 of the seam on the side with little temperature change (usually the indoor side) is a non-elastic adhesive material 2-2 (If the cement polymer mortar is prepared with a synthetic resin adhesive with a glass transition temperature above 0°C, there will be no elasticity); Or the prefabricated roof can adapt to temperature changes.

[0032...

Embodiment approach 3

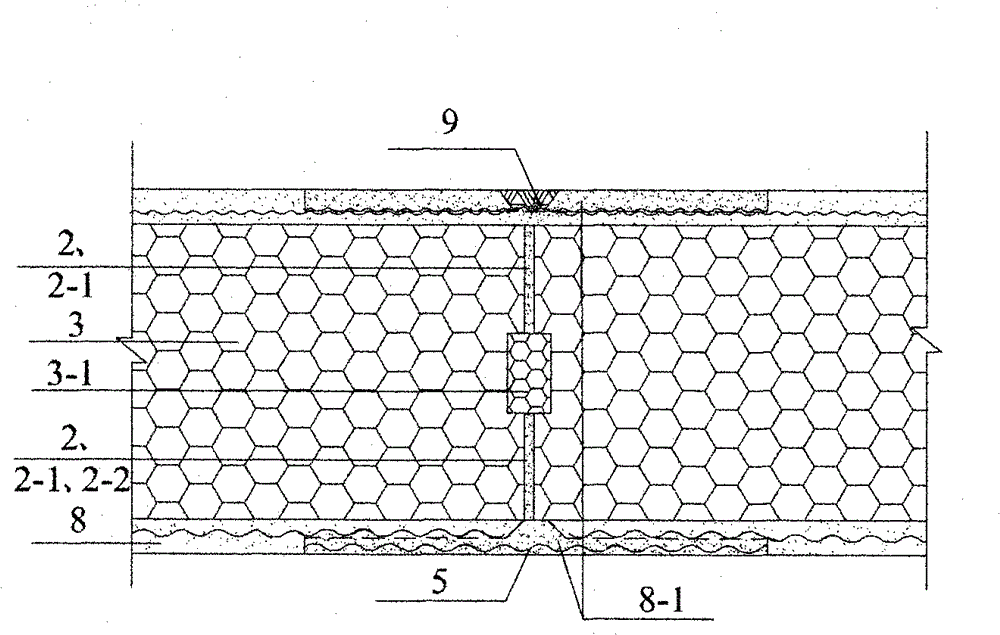

[0041] Implementation mode three: see Figure 5 , an elastic joint structure of the present embodiment, which is composed of a base wall 10, an insulating layer 3, a cement polymer elastic mortar 8-1, a protective layer 8 and a mesh tensile material 5; the base wall 10 is a concrete wall, a brick wall, a block wall, and a lightweight filled wall with cement fiber boards and silicon-calcium boards installed on the keel; the mesh tensile material 5 is metal mesh or alkali-resistant mesh cloth or basalt fiber mesh cloth ; The thermal insulation layer 3 is installed on the base wall 10, and there is a protective layer 8 on the outside of the thermal insulation layer 3, and there is a mesh tensile material 5 in the protective layer 8;

[0042] The cement polymer elastic mortar 8-1 has bonding ability and certain ability to adapt to deformation;

[0043] The elastic joint structure is that there is a cement polymer elastic mortar 8-1 in a certain range at the outer end of the joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com