Prefabricated reinforced concrete hollow web girder and construction method thereof

A reinforced concrete and hollow beam technology, applied in joists, girders, trusses and other directions, can solve the problems of collision, inability to flexibly adjust the position of embedded parts, inconvenient to change, modify and adjust the pipe layout, etc., to facilitate on-site construction, convenient crossing and The effect of embedded parts layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

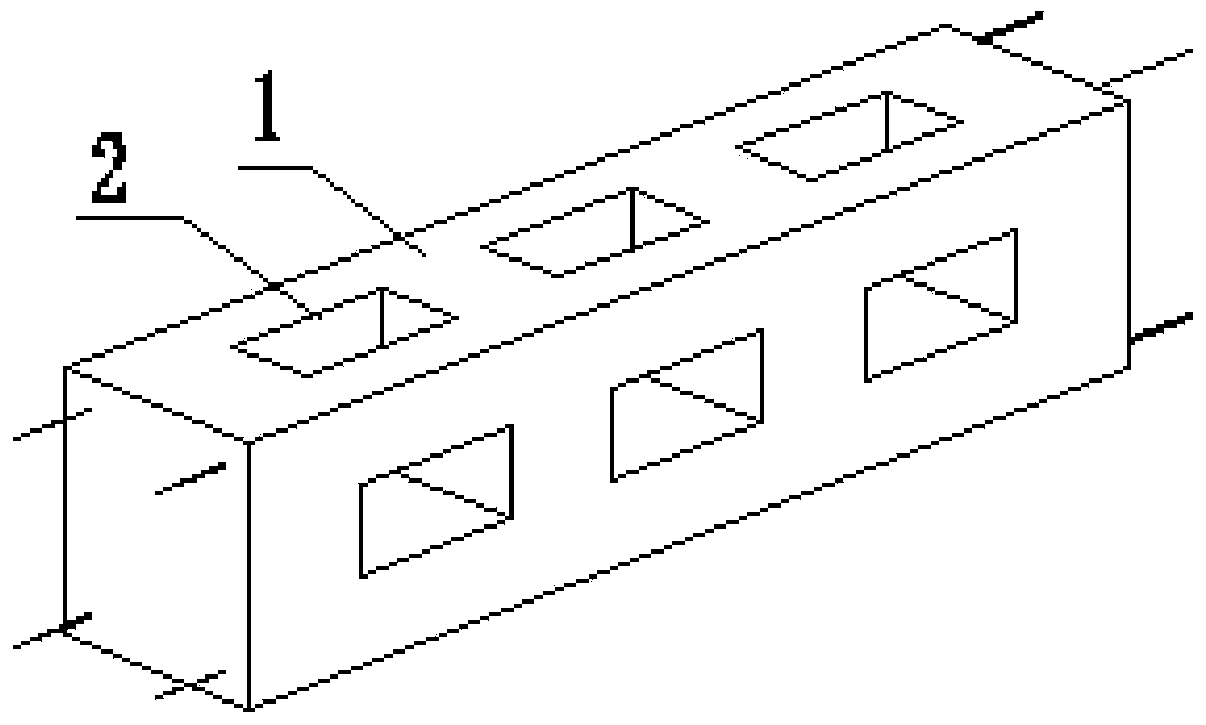

[0032] Such as figure 1 As shown, the longitudinal sections of the prefabricated vierendeel beam extension beam are set into two types: solid section 1 and hollow section 2, and the arrangement and combination of the two sections within the beam length range can be determined according to design and construction requirements.

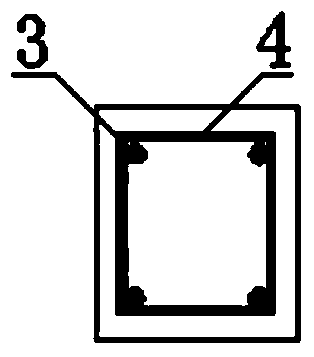

[0033] Such as figure 2 As shown, it is a transverse cross-sectional view of the solid section 1. The number 3 in the figure is a longitudinal reinforcement, and the number 4 is a stirrup. Whether the stirrups in the beam are arranged or not can be selected according to the design load effect.

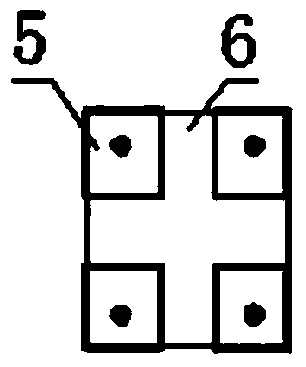

[0034] Such as Figure 3 to Figure 6 As shown, it is a transverse cross-sectional view of the empty stomach section 2, and the number 5 in the figure is reinforced concrete, and the number 6 is a cavity. The structural form of the cavity 6 can consider two factors: the direction of the hole and the closure of the hole end. The direction of the hole means tha...

Embodiment 1

[0036] Such as image 3 As shown, the cavity 6 is a two-way hole and two-way non-closed form, that is, holes are respectively opened in the horizontal direction and the vertical direction along the transverse direction of the beam, and the holes in the horizontal direction and the holes in the vertical direction are not closed, and both ends are transparent. .

Embodiment 2

[0038] Such as Figure 4 As shown, the cavity 6 is a two-way hole with one end closed and the other unclosed, that is, holes are respectively opened in the horizontal direction and the vertical direction along the transverse direction of the beam, wherein the holes in the horizontal direction are not closed, and the two ends are transparent. One end of the hole in the vertical direction is closed; it is also possible that the hole in the vertical direction is not closed, and both ends are transparent, and the hole in the horizontal direction is closed at one end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com