Multi-item bearing seal rotary shaft system used for laser radar scanning rotating mirror

A lidar and rotary shafting technology, applied in the directions of engine sealing, optics, optical components, etc., can solve the problems of large axial and radial dimensions, equipment influence, and unfavorable equipment miniaturization, and achieve convenient lubrication and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings, but those skilled in the art should understand that the embodiments to be described below are not intended to limit the present invention.

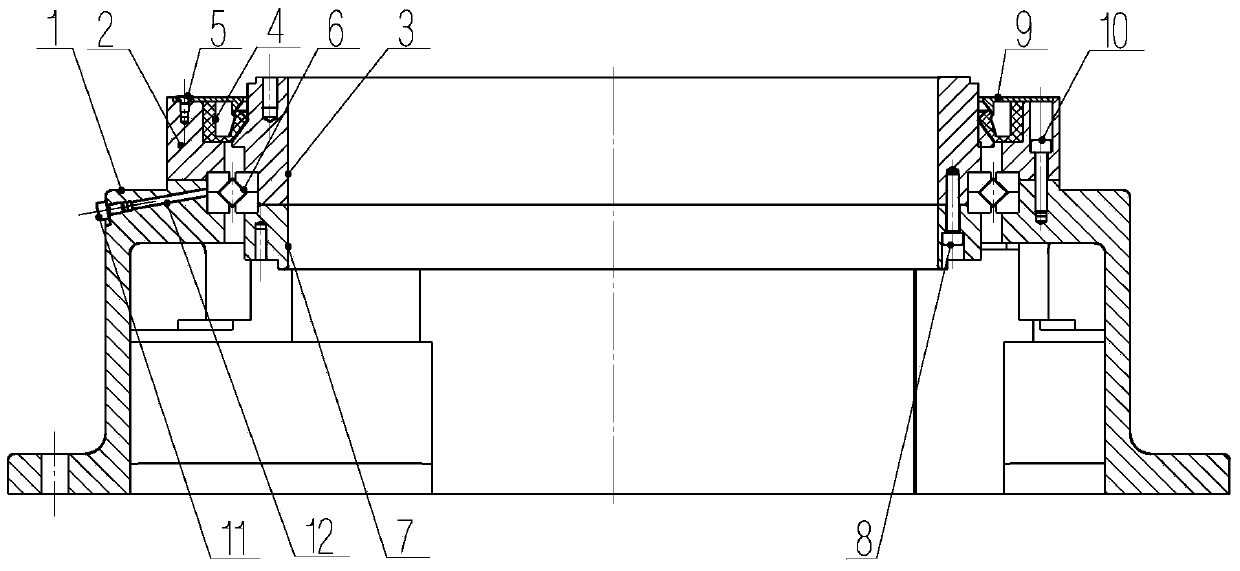

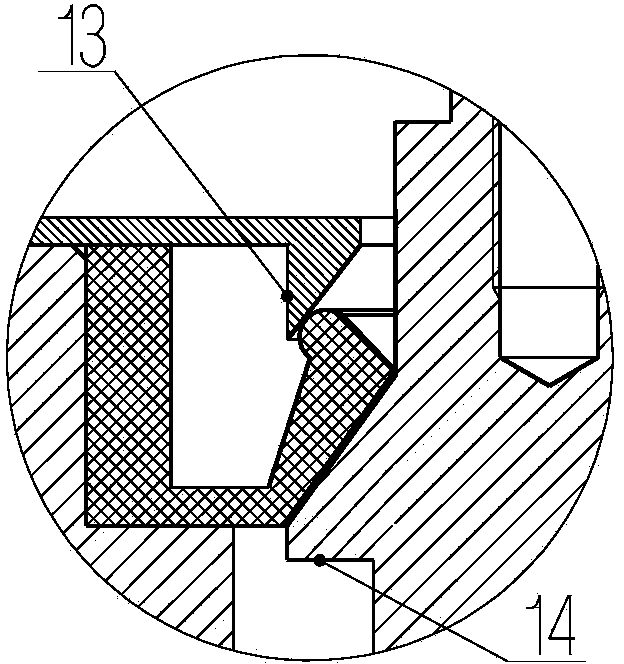

[0022] refer to figure 1 , which shows the multi-directional load-bearing sealed rotary shaft system for the laser radar scanning rotating mirror of the present invention, including the machine base 1, the bearing outer pressure ring 2, the rotating shaft of the laser radar scanning rotating mirror 3, and the fiber reinforced radial oil seal 4 , Screw 5, cross roller collar 6, drive shaft 7, screw 8, oil seal platen 9, screw 10, sealing screw 11, oil hole 12 constitute. There is a stepped part in the bearing hole on the surface of the machine base 1 to fit into the cross roller collar 6, and the lower stepped part of the bearing outer pressure ring 2 presses the outer ring of the cross roller collar 6, and the bearing outer pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com