Rope-free leveling system rubber membrane sealing coal gas cabinet

A technology of rubber seals and gas holders, applied in the field of gas holders, can solve the problems of gas holders that cannot be produced normally, piston rigidity is small, and wire ropes are broken, and achieve the effects of improving competitiveness, reducing steel consumption, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

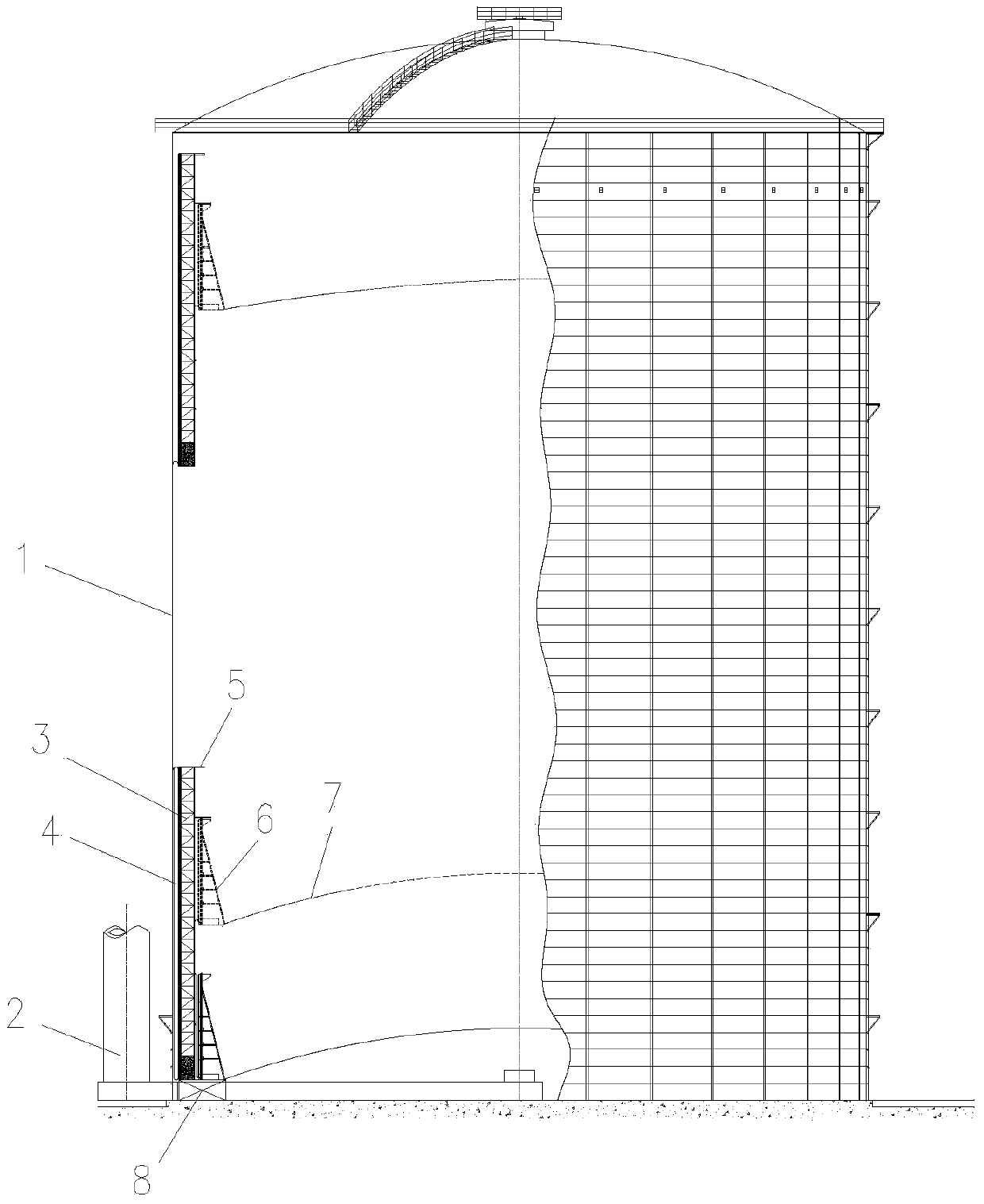

[0016] Such as figure 1 As shown in the figure, the figure shows the working state of the liner piston in three different working positions. The rubber membrane sealed gas holder of the cordless leveling system in the figure includes the gas tank cylinder 1, and the bottom of the gas tank cylinder is provided with a gas The inlet and outlet 2, the gas holder barrel is also provided with a sliding H-type piston that can slide along its inner wall, and the sliding H-type piston includes a cylindrical fence frame 3 that can slide along the inner wall of the gas holder barrel. The outer wall of the cylindrical fence frame is provided with a rubber sealing film 4, the inne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap