Torsional mode magnetostriction sensor array

An array sensor and magnetostrictive technology, applied in the direction of magnetic materials, magnetic objects, permanent magnets, etc., can solve the problems of low energy conversion efficiency, improve energy and signal-to-noise ratio, arrange neatly, improve signal energy and signal The effect of the noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the following examples are only descriptive and not restrictive, and cannot be used to limit the protection scope of the present invention.

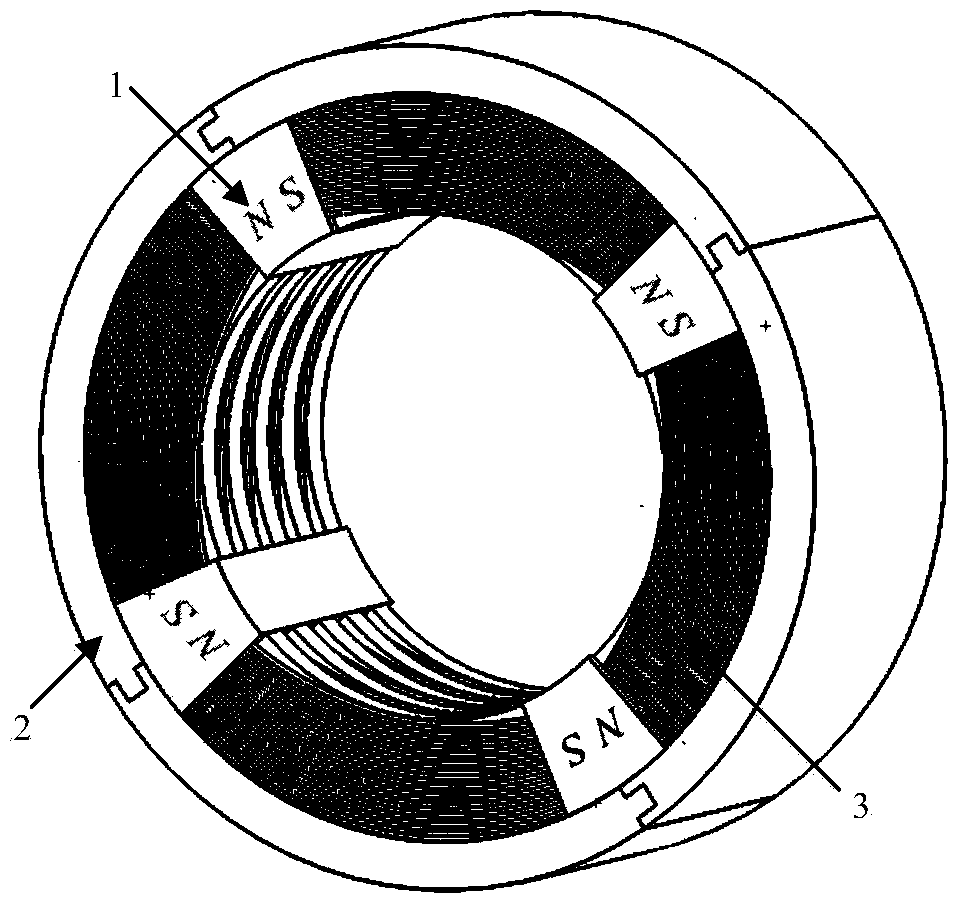

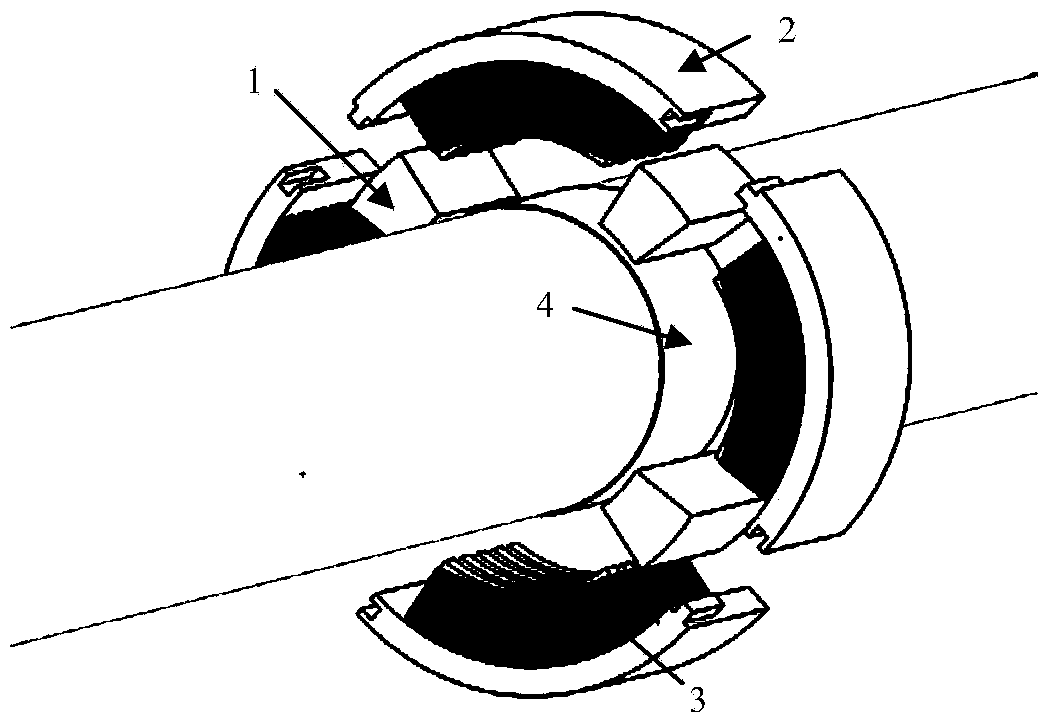

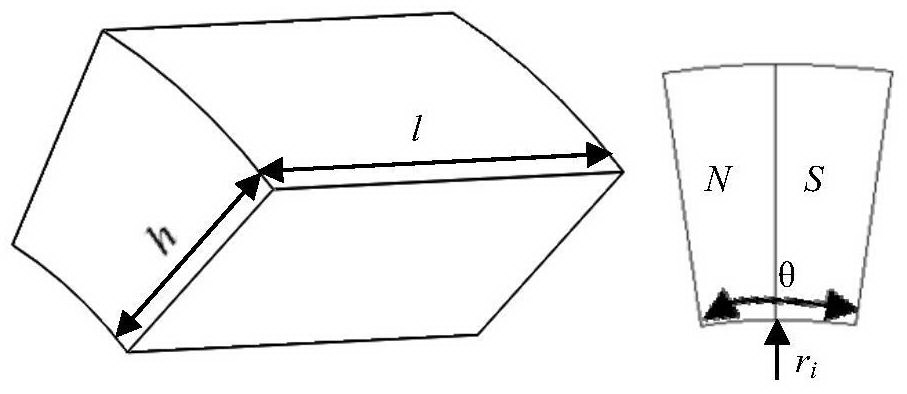

[0038] like figure 1 , figure 2 Schematic diagram of the assembly and disassembly of the torsional mode magnetostrictive array sensor. The magnetostrictive sensor of the improved planar solenoid array MPSA coil is used as the array unit to form a circular array sensor suitable for pipeline detection, that is, the torsional mode magnetostrictive array sensor, including NdFeB magnet 1, sensor housing 2, and MPSA coil 3. Nickel belt4. The detection object is alloy steel pipe, the specification is (unit: mm), the material is 12Cr1MoV alloy steel pipe, the density is 7.85g / cm 3 , Poisson's ratio is 0.27. Image 6 The dispersion curve of the torsional mode in the alloy steel pipe 13 under the above parameters is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com