High solid content water-based adhesive bead planting process and production line

A high-solid content, water-based adhesive technology, applied in the direction of layered products, optics, instruments, etc., can solve the problem that water-based adhesive and bead-planted film are not suitable for transfer and compounding, which affects production and product quality, and has a greater impact on vacuum aluminum plating, etc. problems, to avoid difficult cleaning, prevent static electricity, and achieve good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

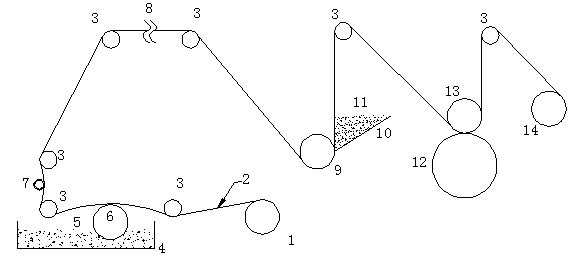

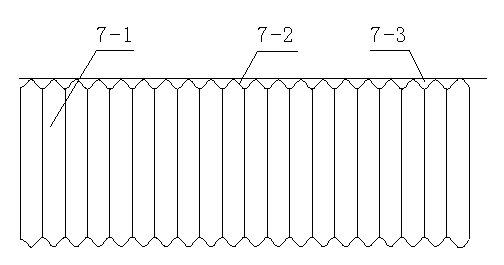

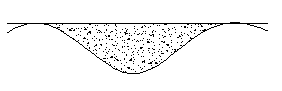

[0012] Embodiment 1: with reference to attached Figure 1-3 . A high-solid content water-based glue bead planting production line, the unwinding roller 1 is located outside the rubber tank 4, the rubberized roller 6 is located in the rubber tank 4, and the front guide roller 3 and the rear guide roller are respectively arranged on both sides of the rubberized roller 6 3 and the roll surface of the front guide roller 3 and the rear guide roller 3 is lower than the roll surface of the unwinding roller 1 and the rubber roller 6, the wire guide roller 3 is located above the rear guide roller 3, and the wire bar 7 is located between the rear guide roller 3 and the wire guide Between the rollers 3 and the smearing surface of the wire rod 7 is lower than the film passing surface of the rear guide roller 3 and the wire guide roller 3, the oven 8 is set above the glue tank 4 and the inlet and outlet ends of the oven 8 are respectively equipped with a guide roller 3 and a bead planting ...

Embodiment 2

[0014] Example 2: On the basis of Example 1, a high-solid content water-based glue bead planting process, the PET film 2 of 1.0-5.0CS passes through the unwinding roller unwinding 1, the guide roller 3 enters the glue groove 4 and is located in the glue groove After the rubberized roller 6 in 4 is glued to one side of the PET film 2, a 10-80g wire rod 7 is used to smear the glued surface, and then enters the oven (8) for drying and drying, and then passes through the bead planting roller 9, microbeads The glass beads 11 in the tank 10 and the bead tank 10 plant beads on the dry and viscous plastic surface PET surface, and the PET surface after bead planting enters the composite roller 12 and the pressure roller 13 for extrusion compounding, and finally The winding roller 14 winds up. The water-based glue 5 in the glue tank 4 is an acrylic adhesive with a solid content of 20% to 80%. The thickness of the coating is controlled by the solid content instead of artificially using a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com