Display module and method for manufacturing same

A technology for display modules and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of organic light-emitting display modules such as thickness and poor yield, and achieve the improvement of manufacturing process yield and thickness Effect with weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

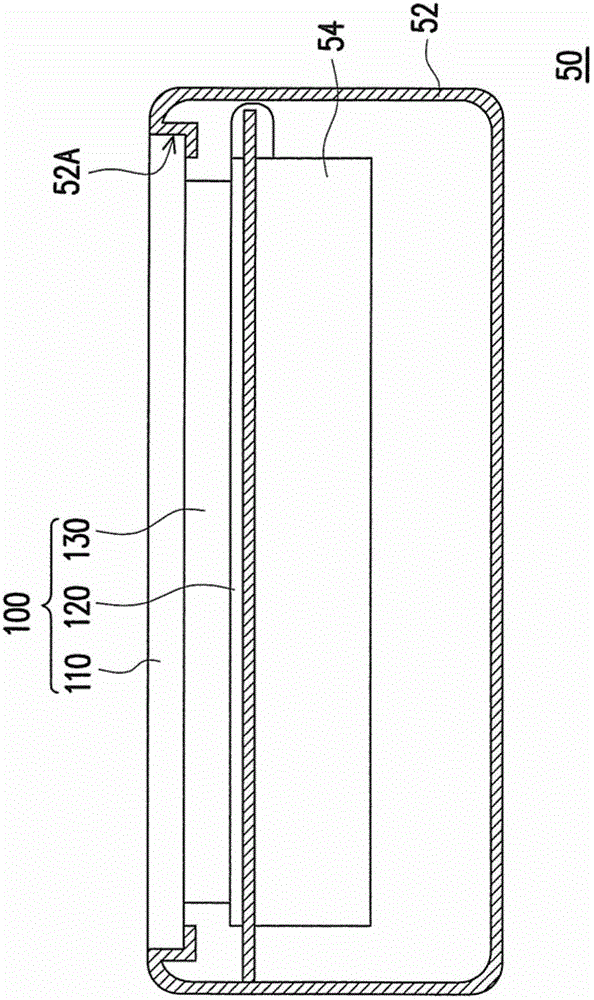

[0047] figure 1 It is a schematic cross-sectional view of a handheld electronic device according to an embodiment of the present invention, wherein the size ratio of each component has been adjusted for clarity. Please refer to figure 1 , the handheld electronic device 50 of this embodiment includes a main body 52 , a host system 54 and a display module 100 . The body 52 has a display opening 52A. The host system 54 is disposed in the main body 52 . The display module 100 is disposed on the display opening 52A. The display module 100 includes a transparent cover 110 , a first protective film 120 and an organic light emitting display element 130 . The organic light emitting display element 130 is disposed between the transparent cover 110 and the first protection film 120 , and is electrically connected to the host system 54 . The organic light emitting display device 130 is electrically connected to the host system 54 through a flexible circuit board or other components, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com