Method for producing coating liquid for metal oxide film, coating liquid for metal oxide film, and metal oxide film

A technology of oxide film and manufacturing method, applied in metal material coating process, application, coating and other directions, can solve the problems of complicated manufacturing process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

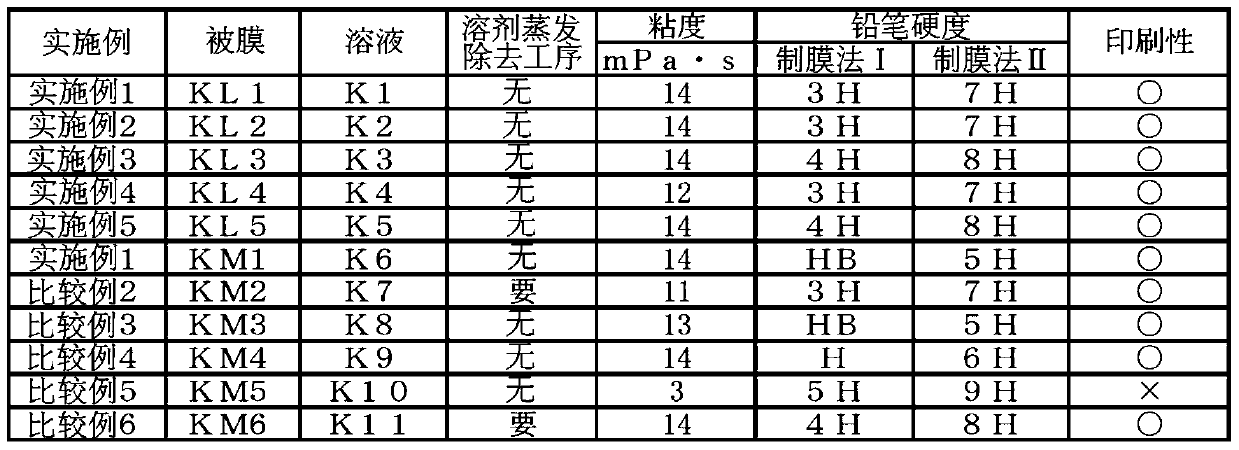

[0117] Hereinafter, although the Example of this invention is demonstrated more concretely, it should not be construed as being limited to these Examples.

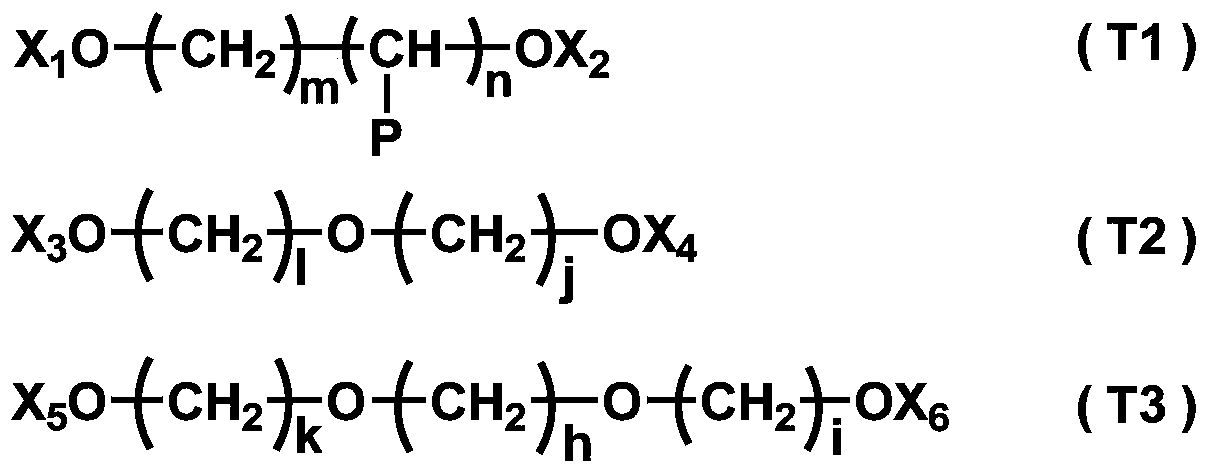

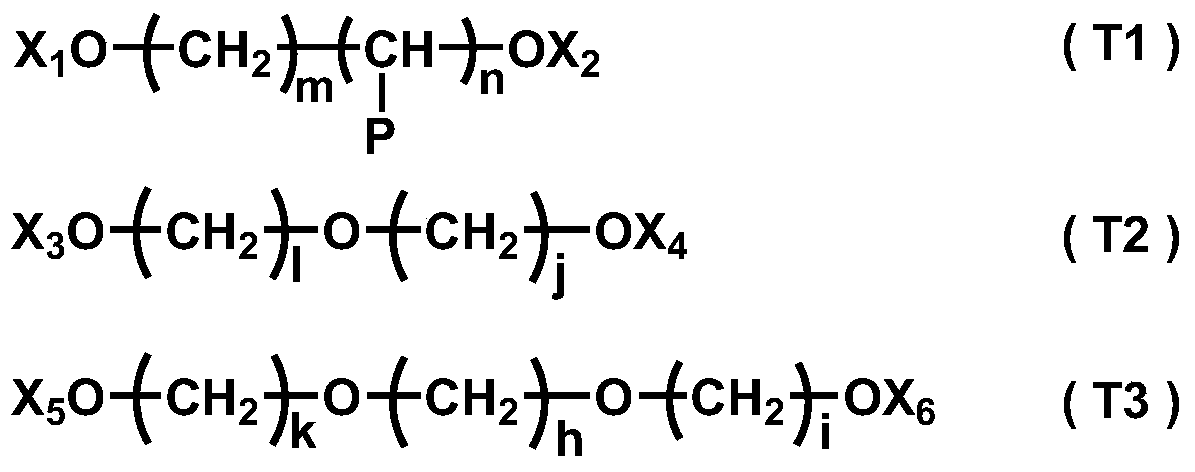

[0118] The abbreviations of the compounds used in this example are as follows.

[0119] TEOS: Tetraethoxysilane

[0120] UPS: γ-ureidopropyltriethoxysilane

[0121] MPMS: Methacryloxypropyltrimethoxysilane

[0122] MTES: Methyltriethoxysilane

[0123] TTE: Tetraethoxytitanium

[0124] TIPT: titanium tetraisopropoxide

[0125] AN: aluminum nitrate nonahydrate

[0126] EG: ethylene glycol

[0127] HG: 2-methyl-2,4-pentanediol (alias: hexanediol)

[0128] BCS: 2-butoxyethanol (alias: butyl cellosolve)

[0129] PGME: Propylene Glycol Monomethyl Ether

[0130] EtOH: ethanol

[0131] InN: indium nitrate trihydrate

[0132] ZTB: tetra-n-butyl zirconate

Synthetic example 1

[0134] 11.9 g of AN and 2.8 g of water were added to a 300 mL flask and stirred to dissolve AN. BCS25.8g and TTE12.4g were added there, and it stirred at room temperature for 30 minutes. Thereafter, 14.7 g of TEOS and 7.5 g of MPMS were added, followed by further stirring at room temperature for 30 minutes. 120.5 g of HG and 4.4 g of BCS were mixed in this solution to obtain a solution (K1).

Synthetic example 2

[0136] 11.9 g of AN and 2.8 g of water were added to a 300 mL flask and stirred to dissolve AN. BCS28.2g and TTE12.4g were added there, and it stirred at room temperature for 30 minutes. Thereafter, 12.6 g of TEOS and 7.2 g of MTES were added, followed by further stirring at room temperature for 30 minutes. HG122.5g and BCS2.4g were mixed with this solution, and the solution (K2) was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap