Medical guiding wire with insulating coating layer and manufacturing method of medical guiding wire

An insulating coating and manufacturing method technology, applied in the field of medical devices, can solve the problems of guide wires without insulating coating, limited range of use, interlaced knotting of catheters, etc., to achieve smooth introduction, low manufacturing cost, and product qualification rate Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

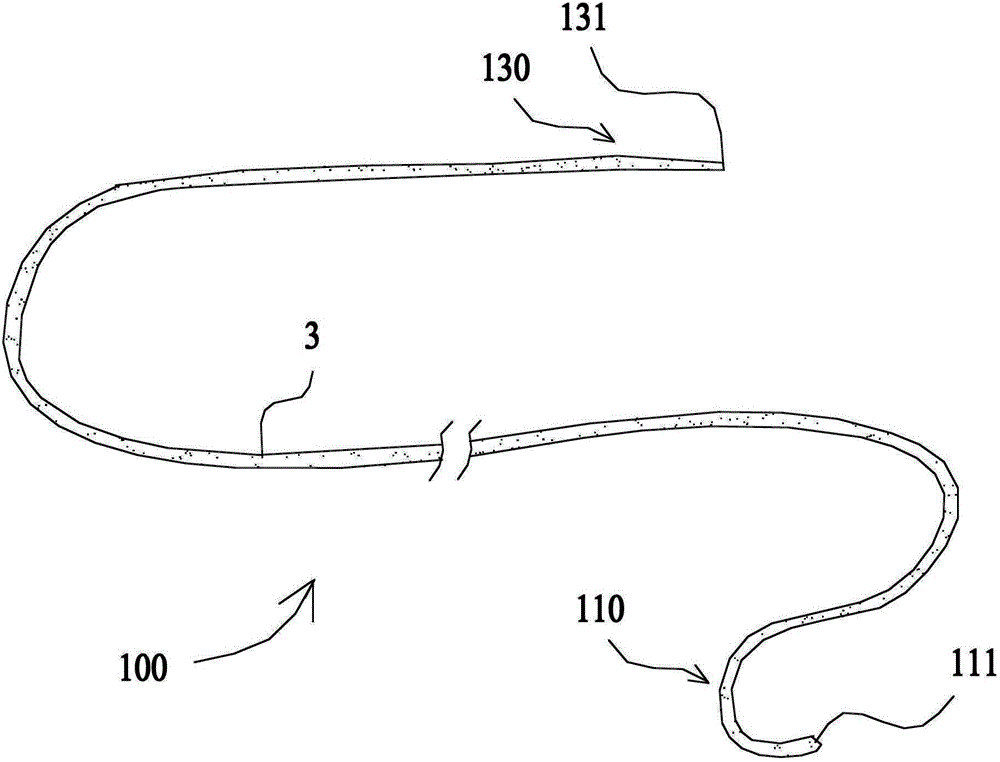

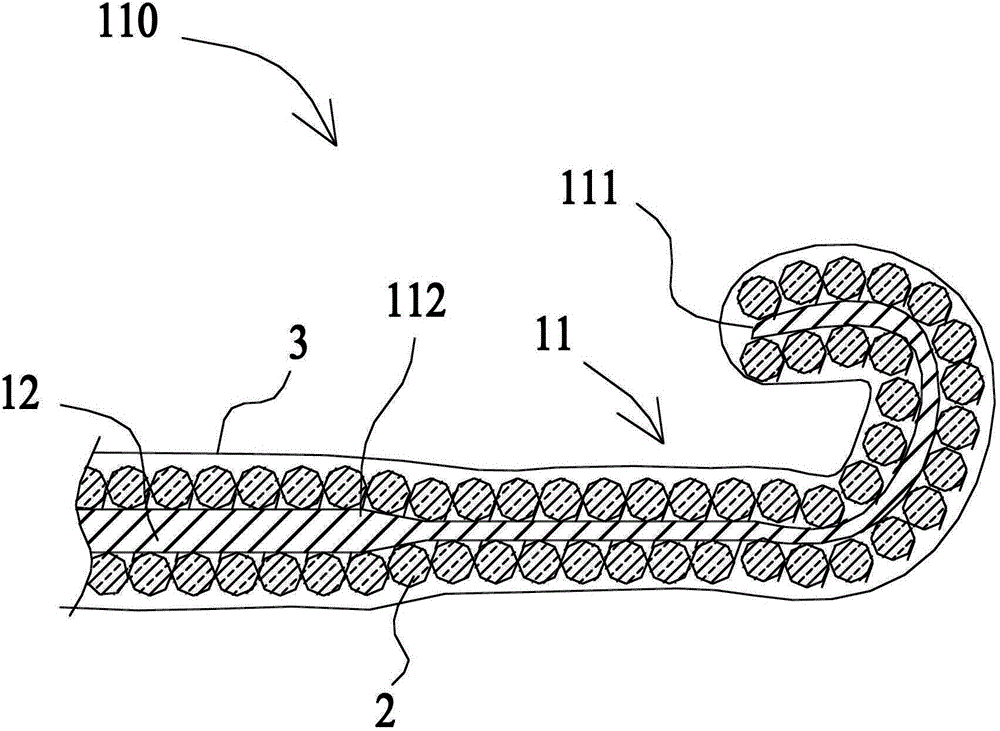

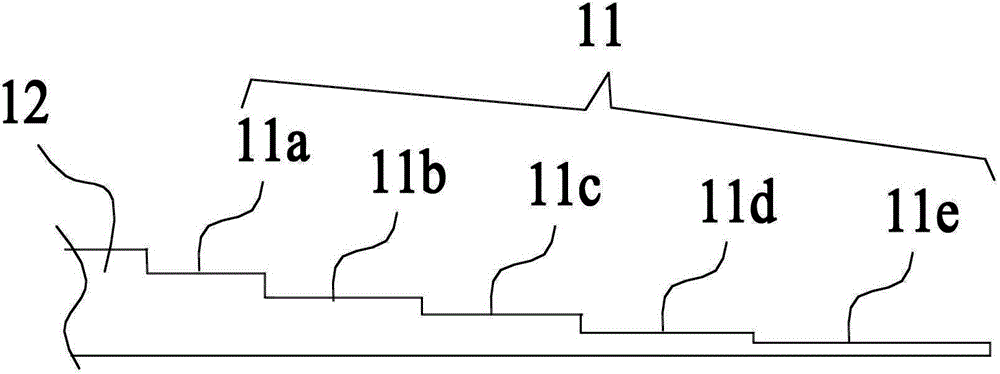

[0071] see figure 1 , figure 2 , Figure 5 As shown, it is a medical guide wire with an insulating coating provided by the embodiment of the present invention. The medical guide wire 100 includes: a core wire, which is made of a metal material and made of a flexible linear body; its head 11 is curved shape, the diameter of the front end 111 of the head 11 gradually increases along the direction of the rear end 112, making the head 11 more flexible relative to the middle part 12 of the core wire; the tail 13 is straight, and the diameter of the end 131 of the tail 13 is along the The direction of the secondary end 112 gradually becomes larger, so that the tail portion 13 is more flexible relative to the middle portion 12 of the core wire; the integral elastic body 2 is made of a metal material in the shape of a coil spring, and the core wire is placed in the elastic body 2 cavity and supports the elastic body 2, the front end 111 and the end 131 are affixed to both ends of t...

no. 2 approach

[0089] see Image 6 , Figure 7 , Figure 8 , Figure 9 , which is a medical guide wire with an insulating coating provided by the embodiment of the present invention. The general structure and manufacturing method of the medical guide wire 200 are the same as those in the first example, and the same parts will not be described again; The difference is that it has two heads 210 and 220; both are curved.

[0090] On the basis of the full description of the first embodiment, in the second embodiment, the materials of the core wire 202 and the elastic body can be changed to 316 or MP35N metal steel wire or nickel-titanium alloy, etc. The length and diameter of the core wire 202 and the elastic body can also be adjusted according to needs; the following is an explanation that can be adjusted flexibly, and further detailed description, the core wire used for the core wire is made A, and the grinder used in the core wire manufacturing step 2 is a centerless grinder , the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com