A Microwave Heating Modification Method for Enhancing Basic Groups on the Surface of Activated Carbon

A technology of microwave heating and surface alkalinity, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effect of expanding the scope of application, low price, and enhancing surface alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

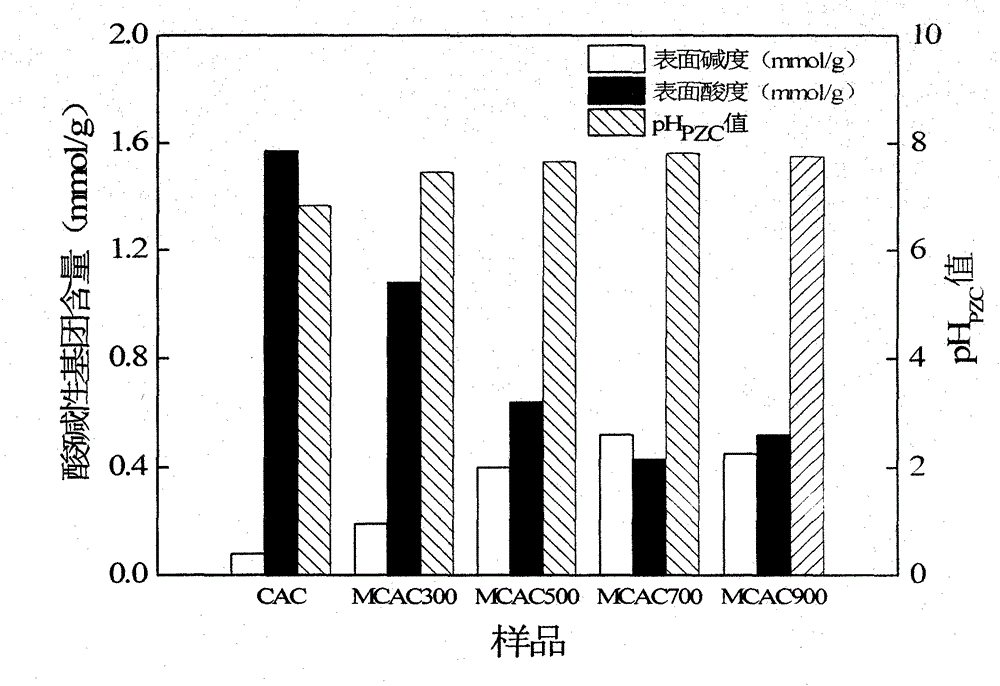

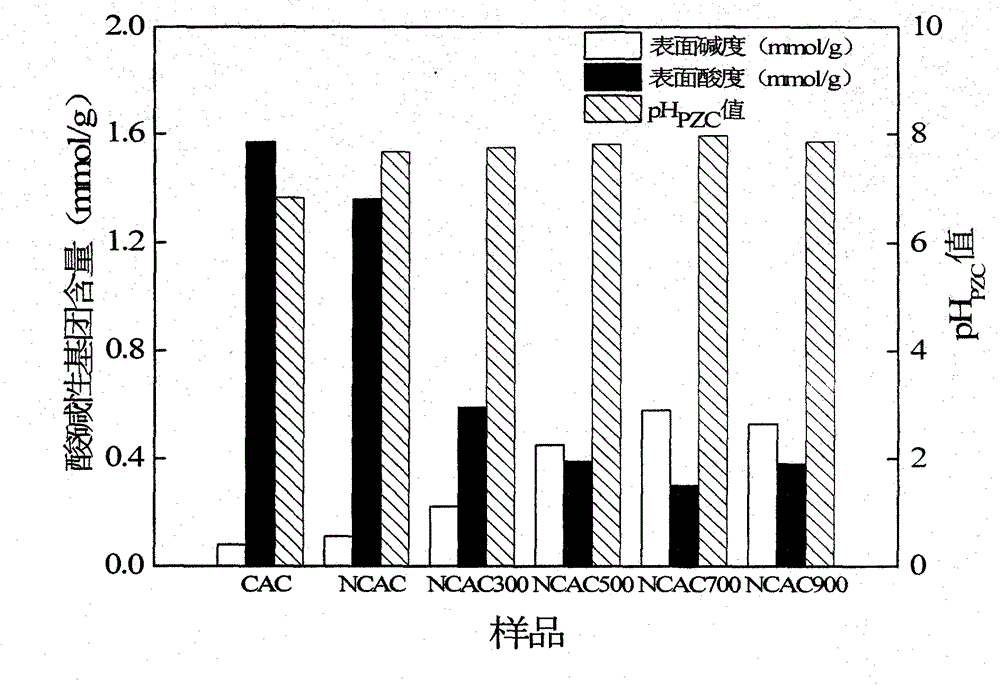

Embodiment 1

[0023] Weigh and mix uniformly raw coal-based activated carbon and ammonia modified (10% ammonia concentration, treatment time 12h, treatment temperature 35 ℃) treatment activated carbon respectively 3.0g, placed in a quartz tube and installed on the refitted microwave reactor , at N 2 Under protection, set the microwave time to 15min, and the microwave power to 300W for microwave heating modification. After the modification reaction was finished and cooled, the samples prepared by microwave modification were MCAC300 and NCAC300, respectively. Then the prepared modified sample was washed with 0.1mol / L HCl and 0.1mol / LNaOH, and then distilled water until the filtrate pH=7, and dried in an oven at 110°C for 12h to obtain activated carbons prepared in two modified ways. The surface basic groups of the modified activated carbons MCAC300 and NCAC300 prepared under the two conditions were 0.19mmol / g and 0.22mmol / g, and the surface acidic groups were 1.08mmol / g and 0.59mmol / g, respe...

Embodiment 2

[0025] Weigh and mix uniformly raw coal-based activated carbon and ammonia modified (10% ammonia concentration, treatment time 12h, treatment temperature 35 ℃) treated activated carbon 3.0g, placed in a quartz tube and installed on the refitted microwave reactor , at N 2Under protection, set the microwave time to 15min, and the microwave power to 500W for microwave heating modification. After the modification reaction was finished and cooled, the samples prepared by microwave modification were MCAC500 and NCAC500, respectively. Then the prepared modified sample was washed with 0.1mol / L HCl and 0.1mol / LNaOH, and then distilled water until the filtrate pH=7, and dried in an oven at 110°C for 12h to obtain activated carbons prepared in two modified ways. The surface basic groups of the modified activated carbons MCAC500 and NCAC500 prepared under the two conditions were 0.40mmol / g and 0.45mmol / g, and the surface acidic groups were 0.64mmol / g and 0.39mmol / g, respectively. g, pH ...

Embodiment 3

[0027] Weigh and mix uniformly raw coal-based activated carbon and ammonia modified (10% ammonia concentration, treatment time 12h, modification temperature 35°C) treated activated carbon 3.0g, respectively, placed in a quartz tube and installed in the modified microwave reactor on, at N 2 Under protection, set the microwave time to 10min, and the microwave power to 700W for microwave heating modification. After the modification reaction was completed and cooled, the samples prepared by microwave modification were MCAC700 and NCAC700 respectively. Then the prepared modified sample was washed with 0.1mol / L HCl and 0.1mol / LNaOH, and then washed with distilled water until the filtrate pH=7, and dried in an oven at 110°C for 12 hours to obtain the activated carbon prepared in two modified ways . The surface basic groups of the modified activated carbons MCAC700 and NCAC700 prepared under the two conditions were 0.52mmol / g and 0.58mmol / g, and the surface acidic groups were 0.43mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com