Mechanical connection type connection pipe inner wall surfacing auxiliary device and method for conducting connection pipe inner wall surfacing through mechanical connection type connection pipe inner wall surfacing auxiliary device

An auxiliary device and mechanical connection technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of long time required to connect ribs, high operating environment temperature, affecting production efficiency, etc., and achieve assembly Simple and fast, improve production efficiency and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

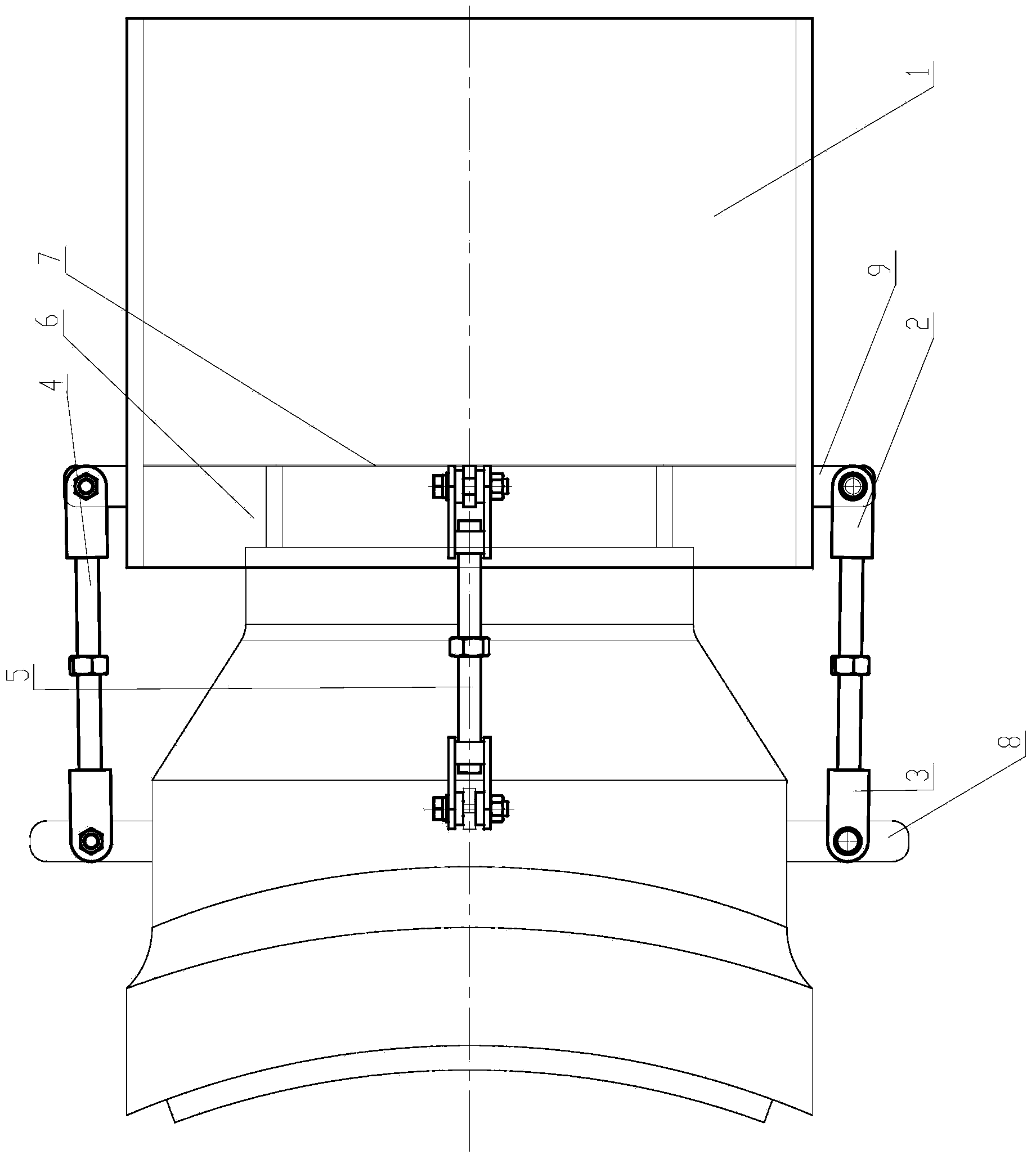

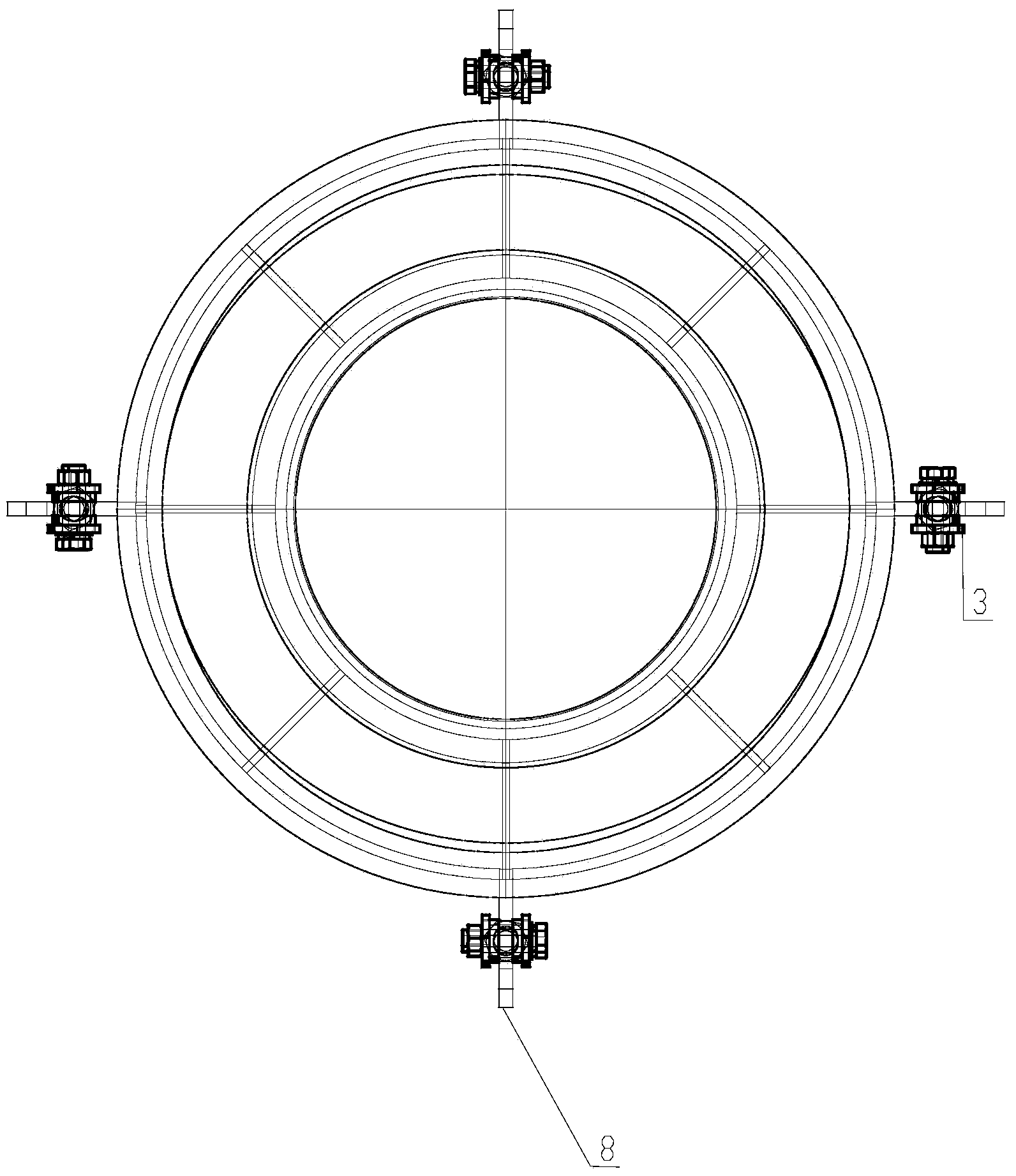

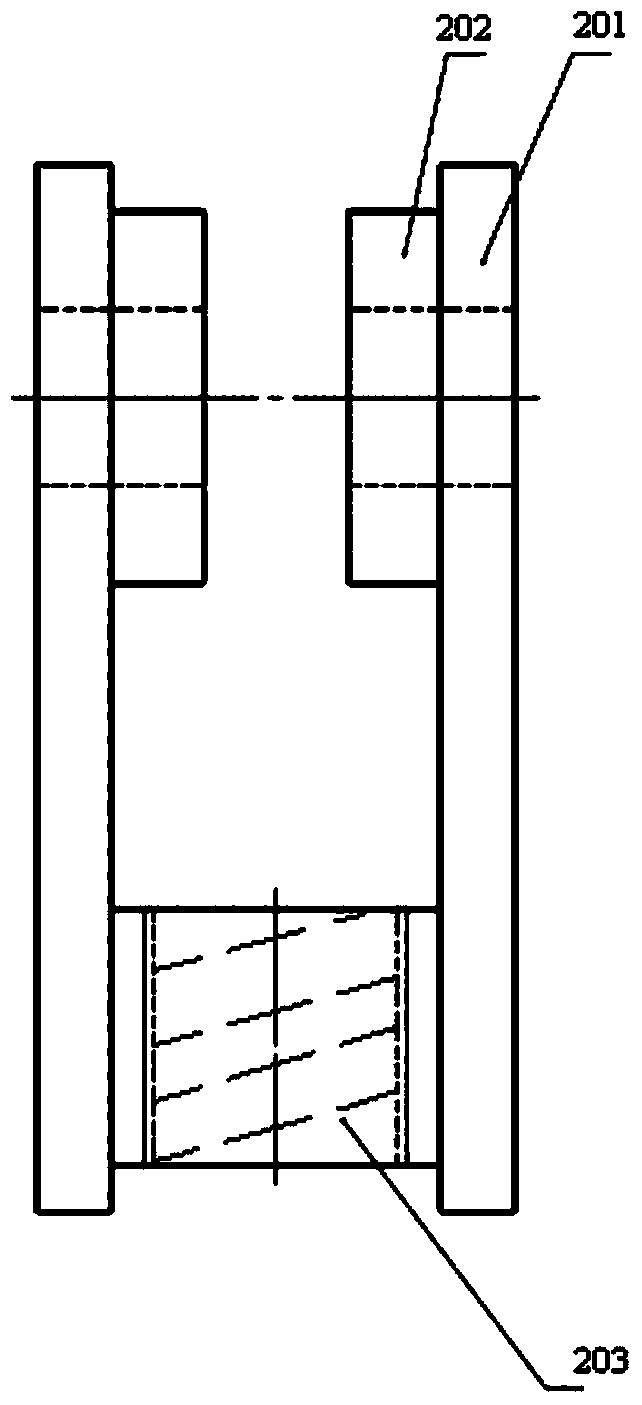

[0032] like figure 1 and figure 2 As shown, a mechanically connected auxiliary device for overlay welding on the inner wall of the connecting pipe, the outer wall of the connecting pipe is stepped, the large diameter end of the connecting pipe is a saddle-shaped end face, and the auxiliary device includes a hollow tubular structure cylinder 1 and Four connection devices, the outer diameter of the cylinder 1 is consistent with the maximum outer diameter of the adapter, so that the central axis of the cylinder 1 and the central axis of the adapter are on the same line, making the whole more stable Placed on the idler roller. The connecting device includes a cylinder connection pull plate 2, a connecting pipe connecting pull plate 3 and a connecting rod, and a connecting pipe end positioning device 6 is provided at the opening of one end of the cylinder body 1 . like Figure 7 and Figure 8 As shown, the nozzle end positioning device 6 includes a tube 602 and eight plates 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com