Blank mold combination surface clamp

A technology that combines surfaces and forms a preliminary mold. It is used in clamping, clamping devices, manufacturing tools and other directions. It can solve the problems of troublesome replacement of parts, unstable parts size, and poor repeat positioning, so as to save materials and ensure The effect of machining accuracy and ensuring production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

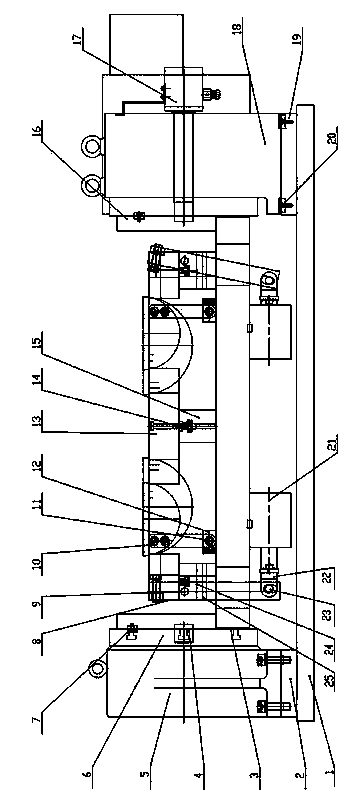

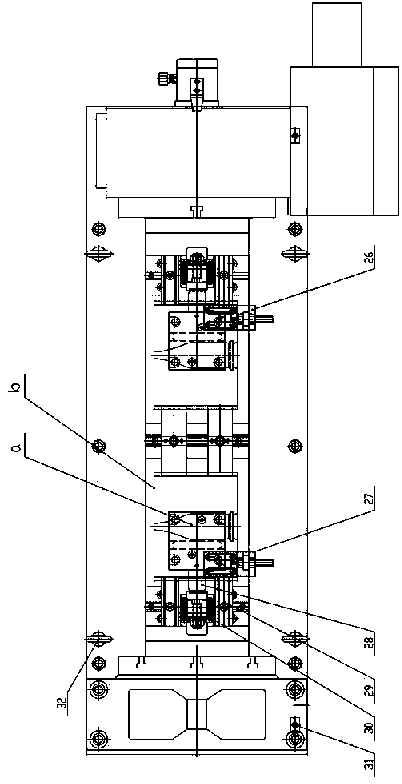

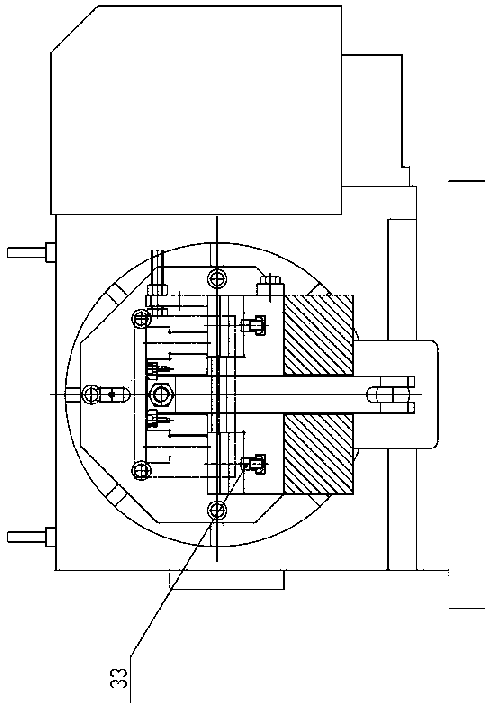

[0018] Such as Figure 1 to Figure 3 Shown are respectively the front view, top view and left view schematic diagrams of the present invention after the joint surface fixture of the blank mold mold is installed with parts.

[0019] A fixture for the joint surface of a mold forming mold, including a turntable tailstock motherboard structure, a side positioning and clamping mechanism, an intermediate positioning mechanism, and a lateral positioning mechanism; wherein two sets of side positioning and clamping mechanisms are installed on both sides of the motherboard, and the female An intermediate positioning mechanism is installed in the middle of the board, and a lateral positioning mechanism is installed behind the motherboard.

[0020] Among them, the mother board structure of the turntable tailstock includes: base plate 1, tailstock pad block 2, motherboard 3, mandrel 4, tailstock 5, tailstock connection plate 6, key A 7, turntable connection plate 16, oil distribution mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com