Method for preparing release agent from waste engine oil

A technology of release agent and waste engine oil, which is applied in the field of preparation of release agent from waste engine oil, to achieve the effects of stable polymerization reaction, high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The main raw materials of the release agent are waste engine oil; anionic emulsifier; silicone oil; industrial sodium hydroxide. The preparation of waste engine oil release agent comprises:

[0028] (1) Pretreatment: dewatering, pickling, alkali washing, adsorption, filtration.

[0029] (2) Preparation:

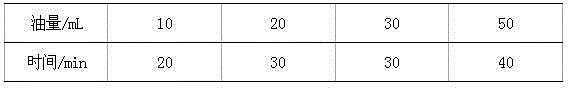

[0030] Step 1: It is mainly for preheating and modifying oil products, which requires high temperature and stirring at a medium speed. Based on 30ml of oil, the required heating temperature is about 90°C, and the heating and stirring time is about 30 minutes. Oil can be increased or decreased, and the time can also be increased or decreased appropriately, generally not less than 20 minutes, as long as there is stable foam on the surface.

[0031] The second step: This stage is to add lye (with CaO or NaOH) to the pretreated oil variety to saponify and complete the emulsification process at the same time. The main conditions are: oil-alkali ratio, water volume, time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com