A refillable gel pen

A gel pen and pen shell technology, applied in ballpoint pens, printing, writing utensils, etc., can solve the problems of high power consumption, stuck, bulky, etc., to reduce the waste of refills, increase the ink storage space, and fill the ink. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

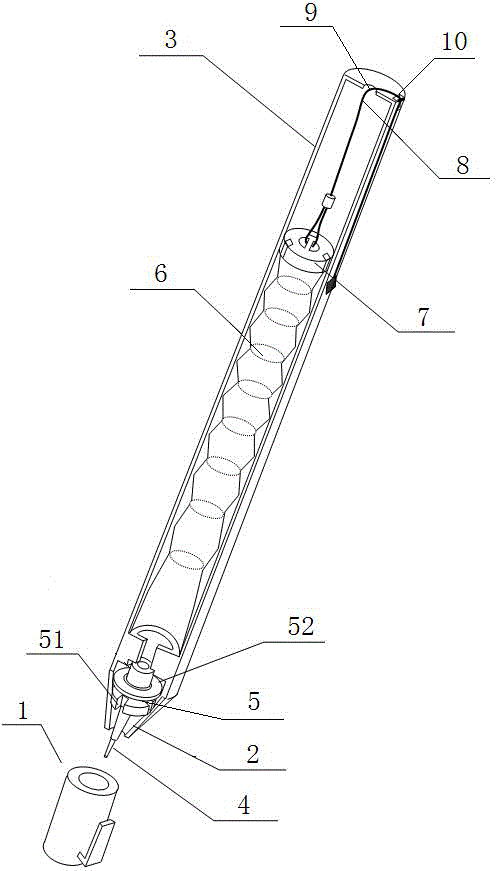

[0021] Such as figure 1 The shown gel pen for refilling ink includes a pen case 3, a pen head 2, and a pen cap 1. The pen head 2 is connected to the pen case 3, and the pen cap 1 is installed on the pen head 2. It is characterized in that: it also includes sequentially connected and The nib 4, the one-way ink valve 5, the ink storage device 6, and the ink pumping device installed in the nib 2 and the pen case 3; An ink leakage hole is provided on the disc 51 .

[0022] There are three ink leakage holes on the ink leakage tray 51, which are evenly distributed along the center of the cylinder. The number of ink leakage holes is set to be three optimal in consideration of the convenience of processing and the effects of ink leakage and ink absorption.

[0023] The one-way ink valve 5 is positioned at the lower end of the ink reservoir 6, and is close to the nib 4 under the normal state, and tightly seals the ink leakage hole, and the ink can only flow out from the nib by hydrau...

Embodiment 2

[0025] As an optimized embodiment of Embodiment 1, the ink reservoir 6 is a compressed ink reservoir with a soft plastic folded structure. Replace the hard ink tube of the existing pen core with a compressed ink storage device, and use a soft plastic ink storage device with a structure similar to the folded structure of a straw. The ink storage device completes the process of filling ink and discharging ink through its volume change , In this way, the piston of the traditional refill is not needed to realize the sealing and flow of the ink, which not only achieves the effect of smoothness but also sealing.

[0026] The ink pumping device includes a one-way limit valve 7 connected to the ink reservoir 6 at one end and an ink pumping control line 8 connected to the other end of the one-way limit valve 7. One end has an outlet hole 9, and the other end of the ink pumping control line 8 passes through the outlet hole 9 of the pen case.

[0027] The outlet hole 9 is arranged at th...

Embodiment 3

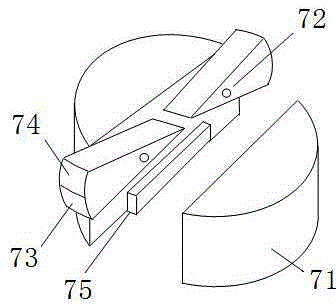

[0030] Such as figure 2 As shown in , as a further optimization of Embodiment 2, the one-way limit valve 7 includes a valve body 71 and a limit block 72 installed on the valve body 71. The body is movably connected, half of the arc-shaped end surface of the limit block is set as a smooth surface 73, and half is set as a rough surface 74, the smooth surface 73 faces the direction of the nib, and the rough surface 74 faces away from the direction of the nib, so that when writing normally, due to the negative pressure, the single The limit valve 7 only moves towards the direction of the nib, and squeezes the compression type ink reservoir to discharge ink.

[0031] As the ink gradually decreases during the writing process, the compressed ink reservoir 6 tends to move downward under the action of gravity, and the smooth surface of the arc-shaped end face contacts the pen shell under the action of friction, so the entire ink pumping device can work normally. When the pen tip move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com