Vortex type automobile exhaust heating device and control method thereof

A technology for automobile exhaust and heating devices, which is applied to vehicle parts, transportation and packaging, and air treatment equipment, etc., can solve problems such as single function, complex structure and control, and difficult start-up, and achieve simple structure, good heating effect, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

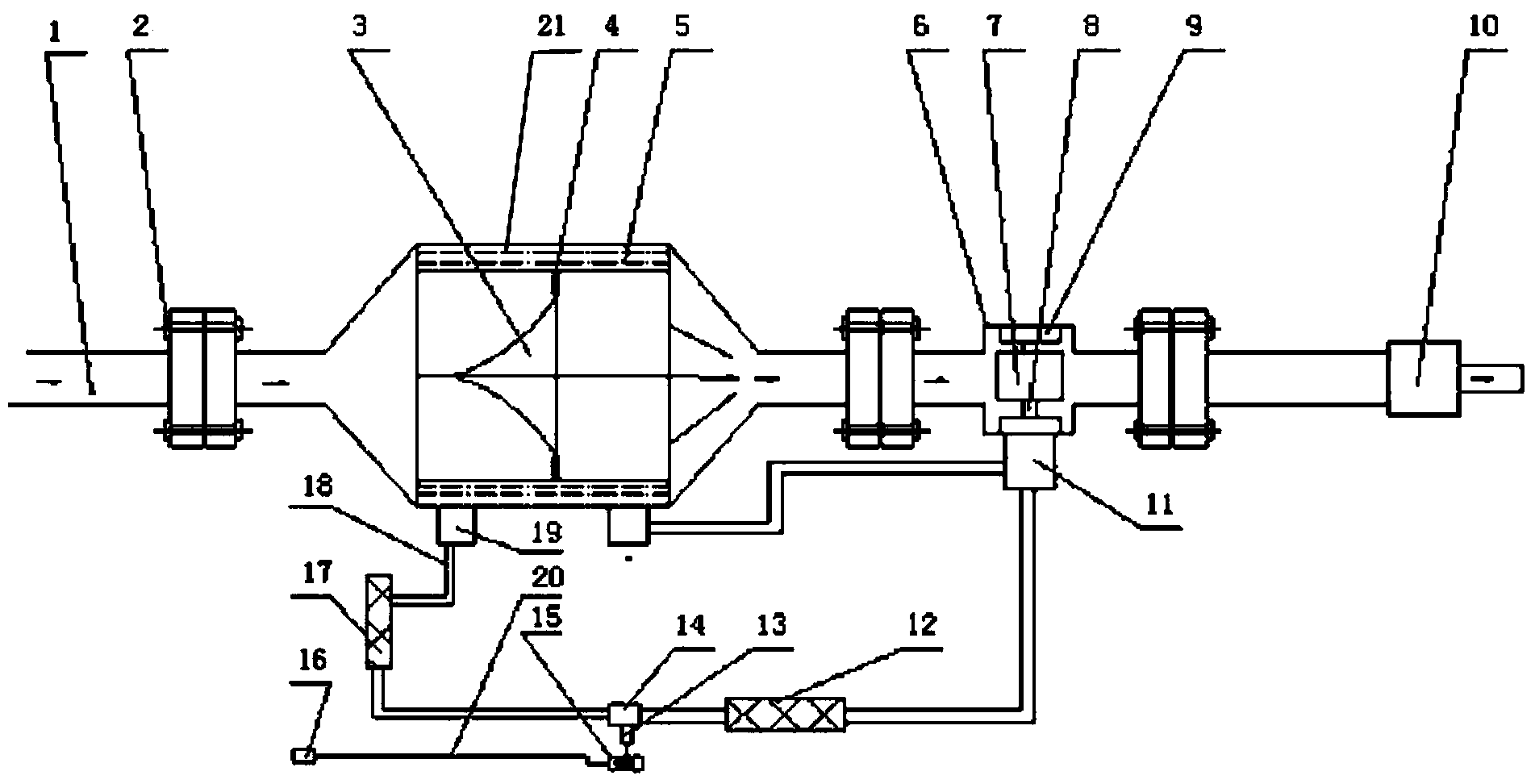

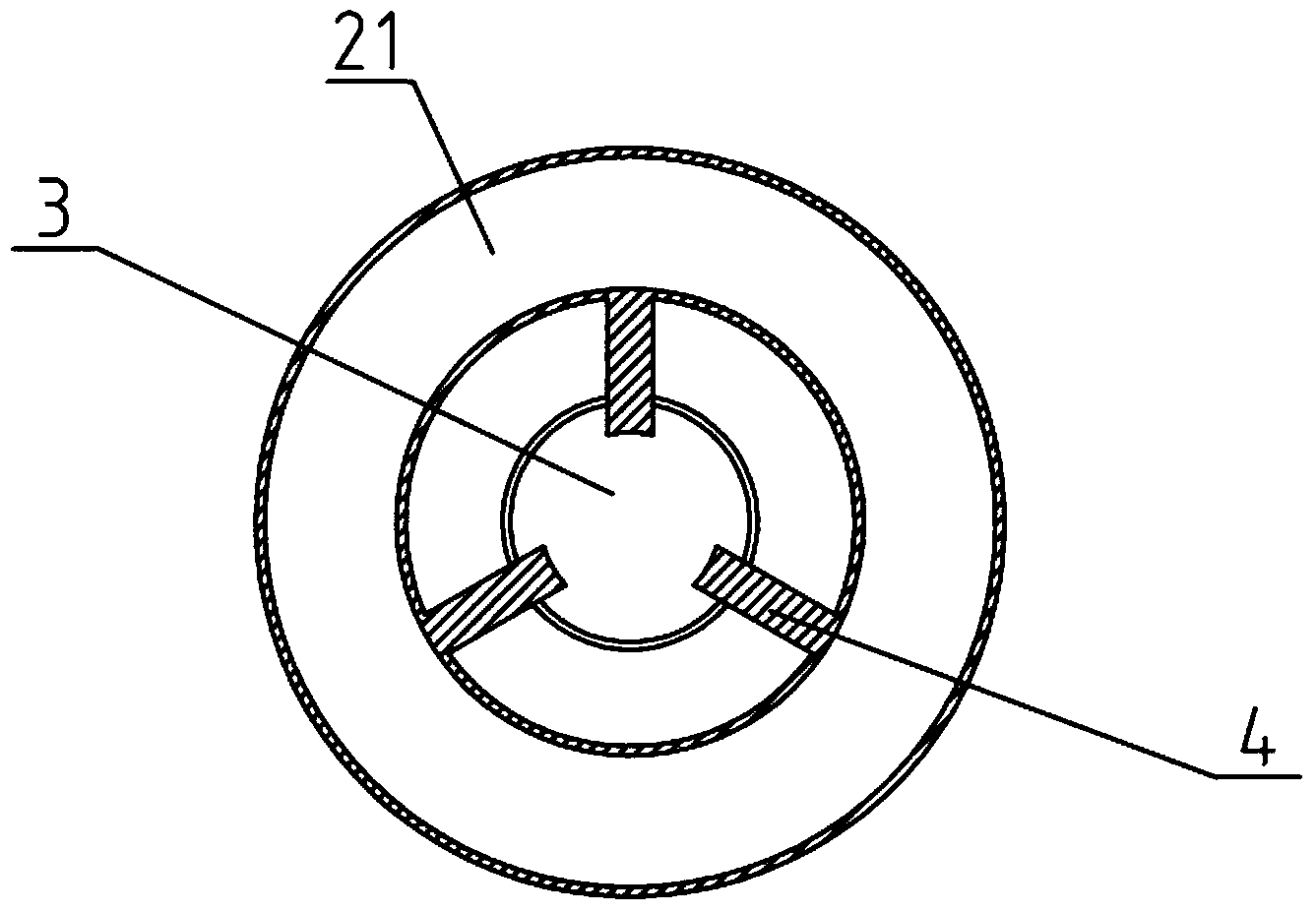

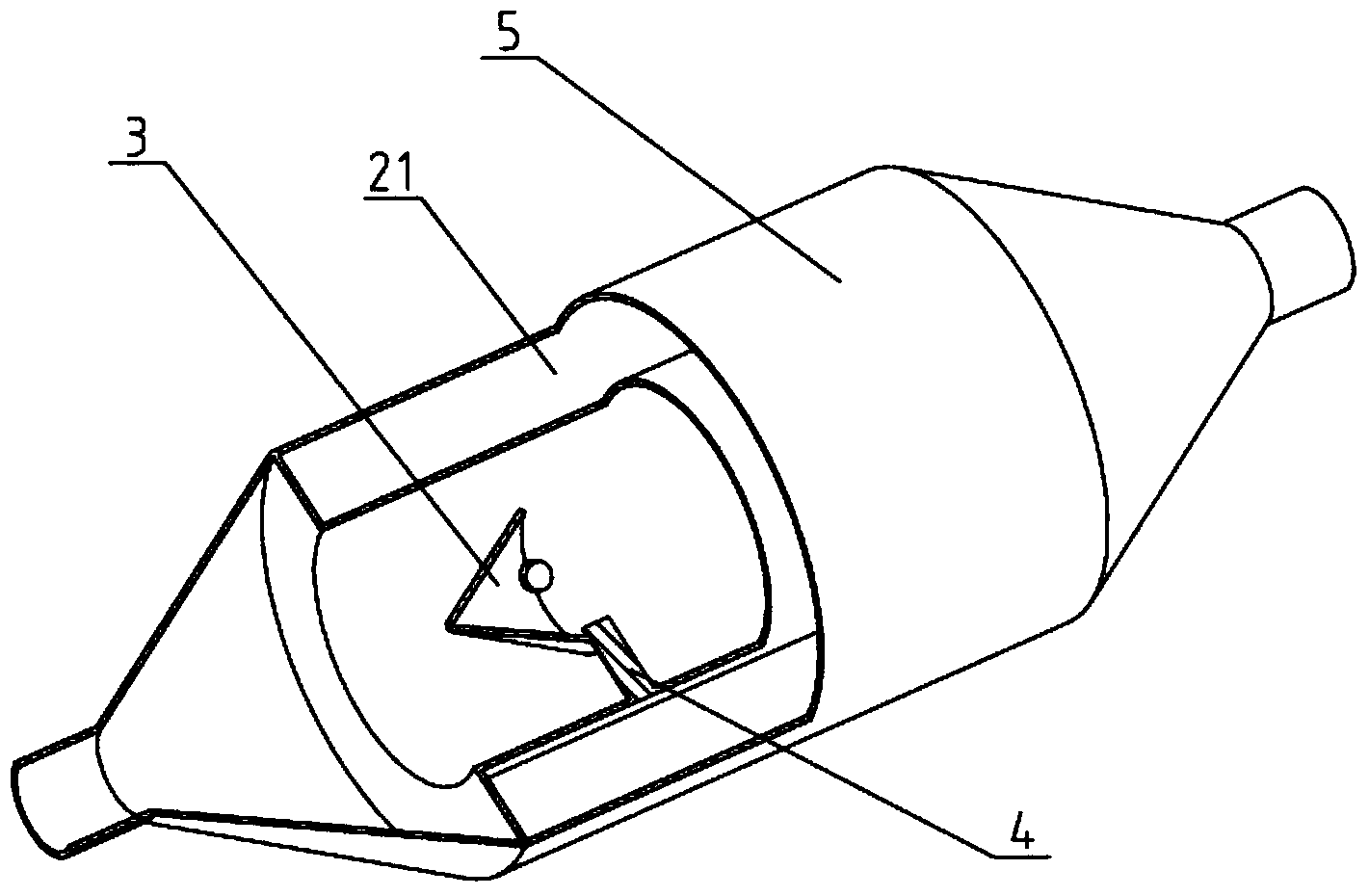

[0032] Such as figure 1 As shown, a vortex type automobile exhaust heating device includes an engine exhaust pipe 1 and a muffler 10, and a heat exchanger is also communicated between the engine exhaust pipe 1 and the muffler 10 from left to right 5 and a water pump housing 6; the heat exchanger 5 is a cylinder, the outside of which is provided with an annular sealed cavity 21 filled with cooling liquid, and a plurality of installation apexes are evenly arranged on the circumferential wall of the cylinder towards the The vortex generator fixing rod 4 of the conical vortex generator 3 of the engine exhaust pipe 1, the bottom of the annular sealing chamber 21 is provided with two water pipe joints 19 connected to the outside; The air direction is provided with a water pump drive shaft 8 with a turbine blade 7 in the middle, a magnetic suspension bearing 9 is provided between the two ends of the water pump drive shaft 8 and the water pump housing 6, and the lower end of the water...

Embodiment 2

[0039] Such as figure 1As shown, a vortex type automobile exhaust heating device, on the basis of the first embodiment, a clutch can also be provided between the water pump drive shaft 8 and the water pump 11 .

[0040] For the control method of the above-mentioned eddy current vehicle exhaust heating device provided with a clutch, the following steps are included:

[0041] a. Start the engine;

[0042] b. controlling the clutch to be closed to make the transmission connection between the water pump 11 and the water pump drive shaft 8;

[0043] c. the temperature control module 15 controls the solenoid valve 13 so that the flow valve 14 is opened;

[0044] d. The temperature control module 15 regularly detects the temperature sensor 16, if the temperature detected by the temperature sensor 16 is lower than a preset value, then controls the solenoid valve 13 so that the opening of the flow valve 14 becomes If the temperature detected by the temperature sensor 16 is higher th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com