Method for producing vortex spinning yarn with color fiber circles

A production method and technology of vortex spinning, which is applied in the field of vortex spinning color dot yarn production, can solve problems such as easy fluffing and pilling, weak adhesion between color dots and yarn cloth surface, and excessive hairiness, so as to achieve firm and unique bonding The effect of appearance color style and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

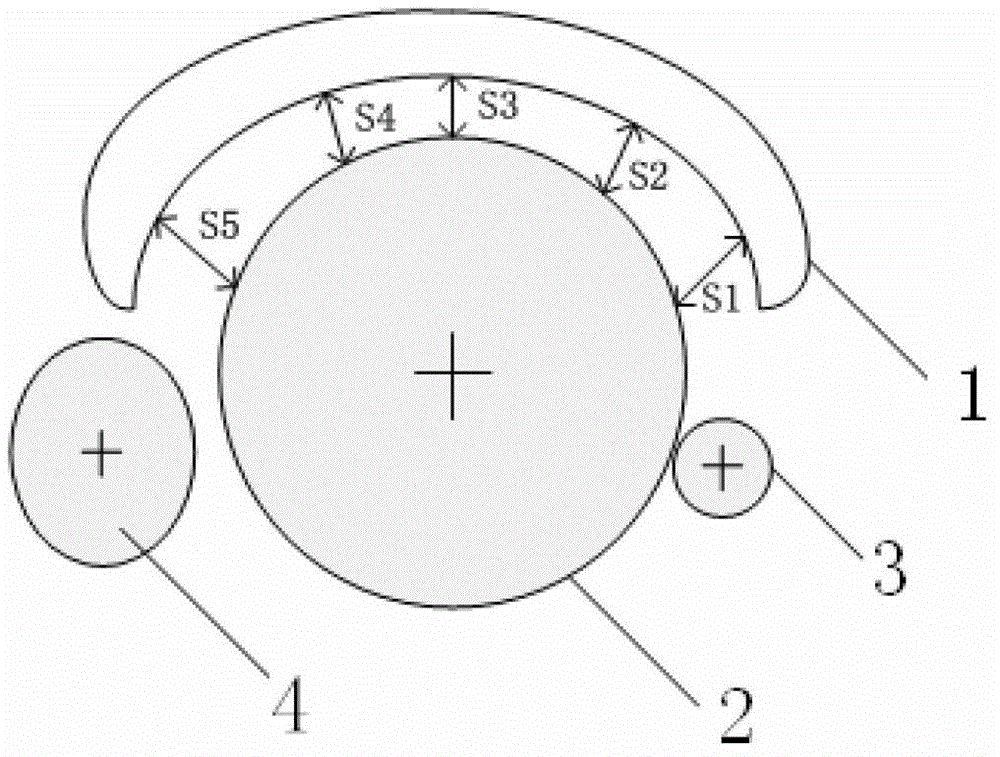

Image

Examples

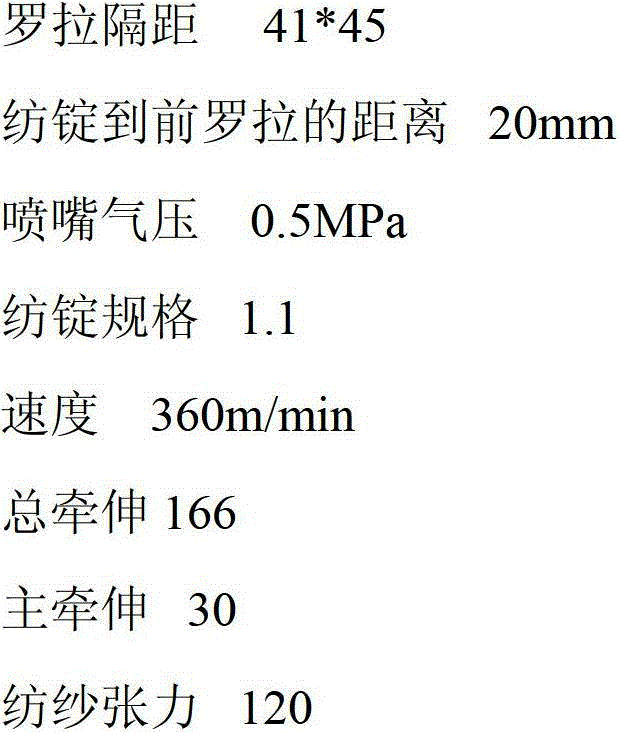

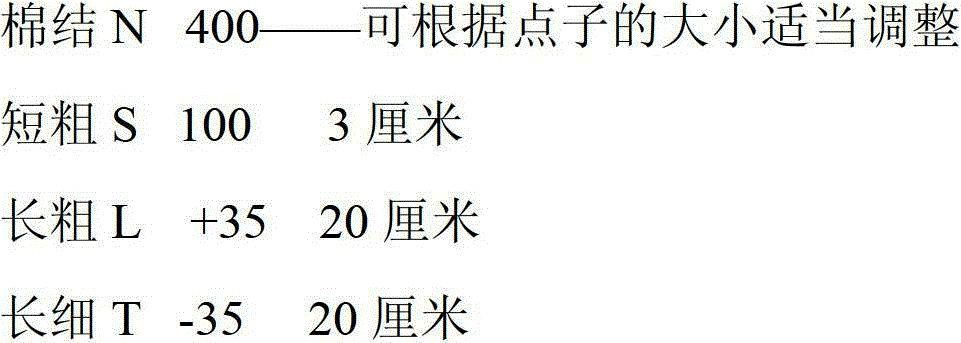

Embodiment 1

[0047] Cotton blending process requirements: according to the weight percentage, 98% viscose / 2% viscose colored dots, the average diameter of the colored dots is 0.8 mm, and the total weight is 100 kg. Quantitative stacking method, the total weight of the mixture is 50KG each time, weigh the materials twice, and mix them manually to make the various raw materials and color points evenly mixed;

[0048] Requirements for the cleaning process: open and further mix the mixed raw materials so that the fiber bundles of each raw material are evenly mixed. Through the cleaning process, the color dots are completely distributed in a granular state. Finally, it is made into a cotton lap, and the dry weight of the cotton lap is 350 g / m; the length of the lap is 36 meters;

[0049] Requirements for the carding process: the cotton laps produced by the blowing process are carded into slivers on the carding machine, and the raw sliver weight is 20 grams / 5 meters; Configured according to co...

Embodiment 2

[0058] Cotton blending process requirements: by weight percentage, 97% viscose / 3% viscose colored dots, the average diameter of the colored dots is 1.0 mm, and the total weight is 1000 kg. Quantitative stacking method, the total weight of the mixture is 50KG each time, weigh the materials twice, and mix them manually to make the various raw materials and color points evenly mixed;

[0059] Requirements for the cleaning process: open and further mix the mixed raw materials so that the fiber bundles of each raw material are evenly mixed. Through the cleaning process, the color dots are completely distributed in a granular state. Finally, it is made into a cotton lap, and the dry weight of the cotton lap is 450 g / m; the length of the lap is 35 meters;

[0060] Requirements for the carding process: the cotton laps produced by the blowing process are carded into slivers on the carding machine, and the raw sliver dry weight is 24 grams / 5 meters; the doffer speed is 15 rpm; the dist...

Embodiment 3

[0069] Cotton blending process requirements: by weight percentage, 98% modal / 2% viscose colored dots, the average diameter of the colored dots is 0.5 mm, and the total weight is 500 kg. Heap mixing method, each time the total weight of the mixture is 50KG, weighing twice, manual mixing evenly, so that various raw materials and color spots are evenly mixed;

[0070] Requirements for the cleaning process: open and further mix the mixed raw materials so that the fiber bundles of each raw material are evenly mixed. Through the cleaning process, the color dots are completely distributed in a granular state. Finally, it is made into a cotton lap, and the dry basis weight of the cotton lap is 350 g / m; the length of the lap is 40 meters;

[0071] Requirements for the carding process: the cotton laps produced by the blowing process are carded into slivers on the carding machine, and the raw sliver weight is 16 grams / 5 meters; the doffer speed is 22 rpm; Configured according to cotton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com