Measurement device and method for fracture shapes after physical model samples are fractured

A crack shape and measuring device technology, applied in the field of petroleum industry, can solve problems such as complex operation, difficult operation, complex equipment, etc., and achieve the effect of accurate identification, convenient use and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

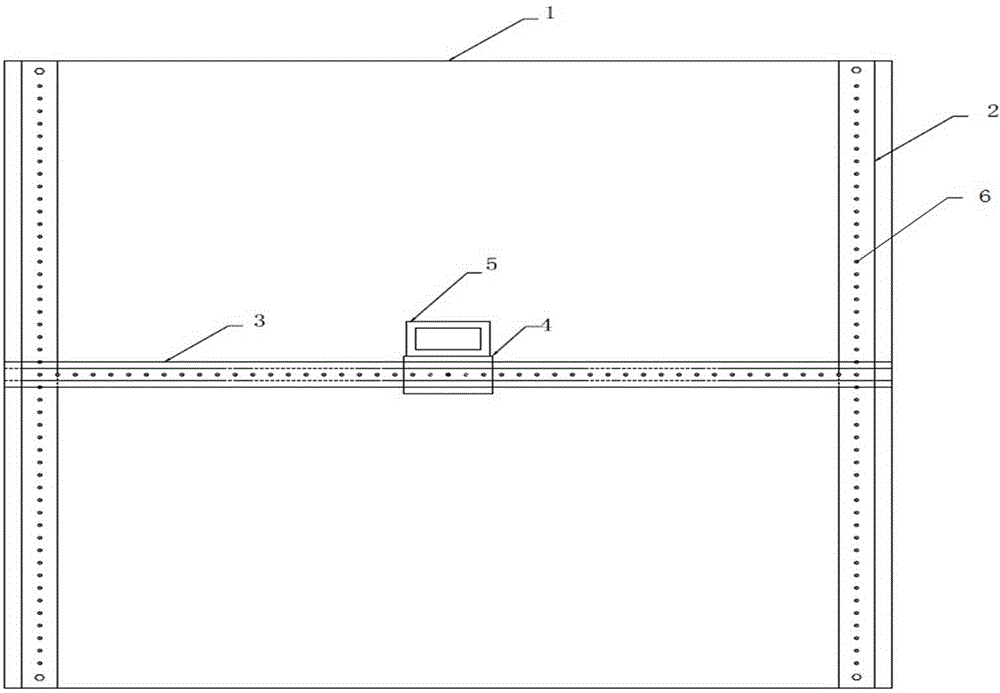

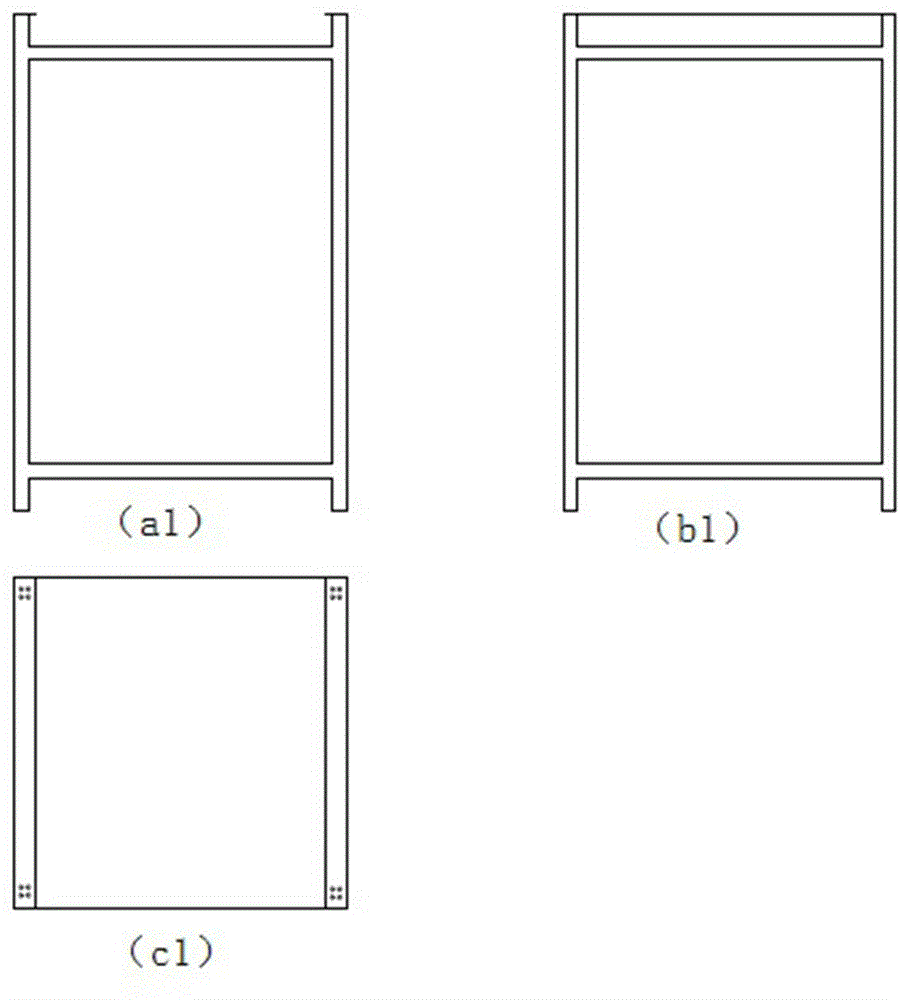

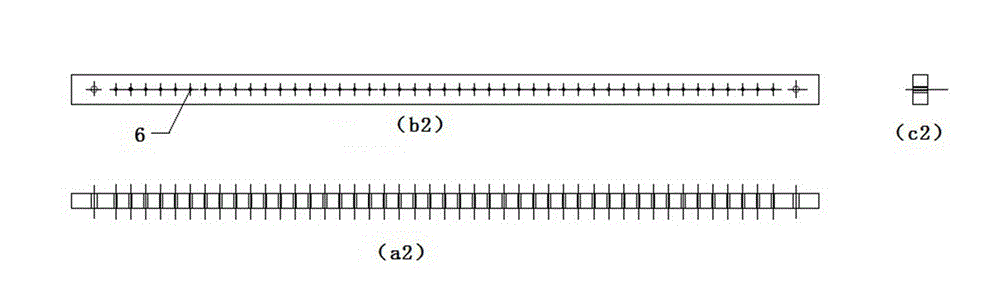

[0049] A device for measuring the fracture shape of a physical model sample after fracturing, such as figure 1 As shown, it comprises a test frame 1, a positioning clamp 2 is installed on the test frame 1, a linear positioning guide rail 3 is installed on the positioning clamp 2, and a positioning slide block 4 is connected on the linear positioning guide rail 3. The positioning slider 4 is fixed together with the positioning box 5, and a laser rangefinder is housed in the positioning box 5, and the positioning slider 4 can drive the positioning box to move laterally on the linear positioning guide rail. The positioning guide rail can move longitudinally on the positioning clip.

[0050] In this embodiment, the positioning clip 2 is fixed on the test frame 1 by bolts, and the linear positioning guide rail 3 is fixed on the positioning clip 2 by positioning pins, and can be positioned on the positioning clip 2. Move vertically.

[0051] In this embodiment, the positioning sli...

Embodiment 2

[0076] A device for measuring the shape of cracks after fracturing of a physical model sample, which includes a test frame 1, a positioning clip 2 is installed on the test frame 1, and a linear positioning guide rail 3 is installed on the positioning clip 2. The linear positioning guide rail 3 is connected with a positioning slider 4, the positioning slider 4 is fixed with the positioning box 5, a laser rangefinder is housed in the positioning box 5, and the positioning slider 4 can drive the positioning The box moves laterally on the linear positioning guide rail, and the positioning guide rail can move longitudinally on the positioning clip bar.

[0077] In this embodiment, the positioning clip 2 is fixed on the test frame 1 by welding, and the linear positioning guide rail 3 is fixed on the positioning clip 2 through positioning pins, and can be positioned on the positioning clip 2. Move vertically.

[0078] In this embodiment, the positioning slide block 4 can slide freel...

Embodiment 3

[0103] A kind of method for measuring the fracture shape after the fracturing of the physical model sample, the device used is the measuring device in embodiment 1, this method is basically the same as that of embodiment 1, and the difference is to include the following steps:

[0104] A, carry out fracturing test to rock core sample, after described rock sample is fractured to produce crack, stop injecting fracturing fluid;

[0105] B, the rock core sample in the step A is opened along the fracture surface of each depressing, be placed on above-mentioned test frame 1 of the measuring device of the fracture form after the fracturing of the physical model sample;

[0106] C. Move the linear positioning guide rail 3 longitudinally along the positioning clip 2, the linear positioning guide rail 3 drives the positioning slider 4 to move, and the positioning slider 4 drives the positioning box 5 to move together, thereby realizing the longitudinal movement of the laser rangefinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com