Coal tar ingredient analysis instrument

A component analysis and coal tar technology, applied in the field of coal tar component analyzer, can solve the problems of difficult to guarantee the accuracy of measurement results, low accuracy of manual observation test, cumbersome process and time cost, etc., to improve test accuracy, reduce operation difficulty, The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

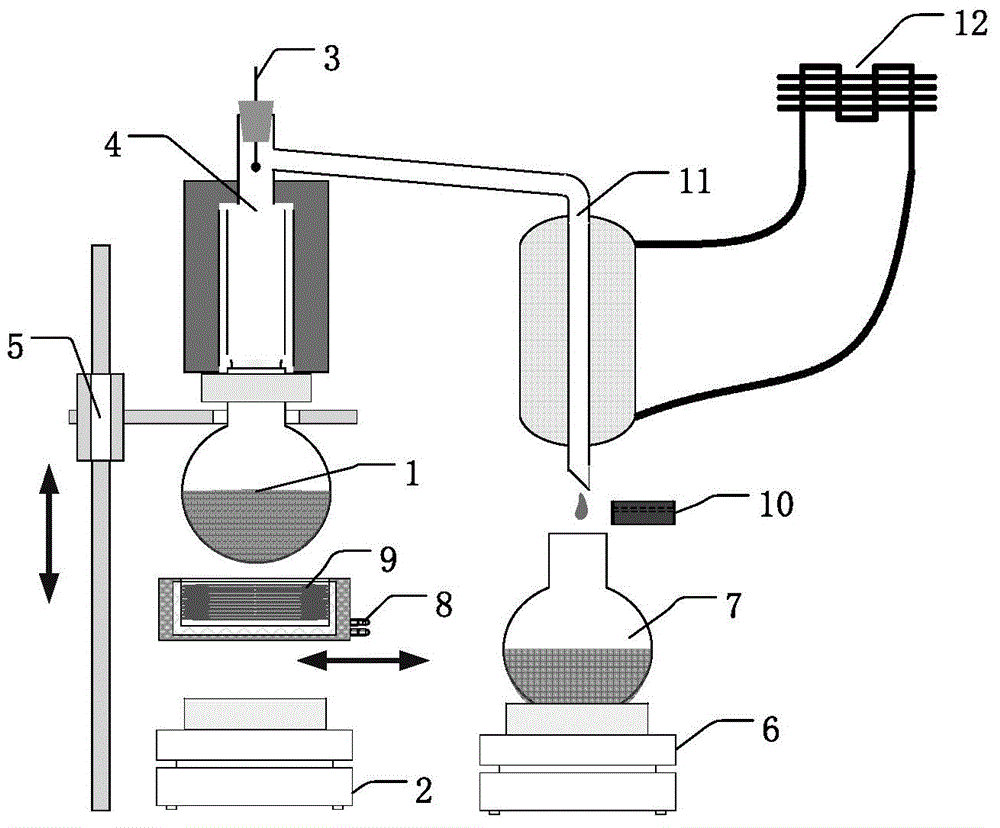

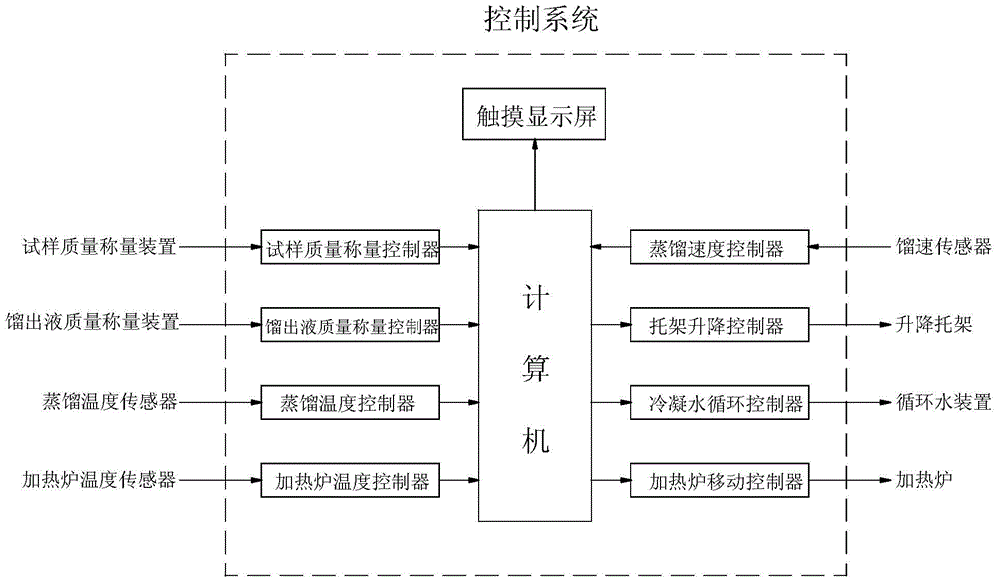

Method used

Image

Examples

Embodiment 1

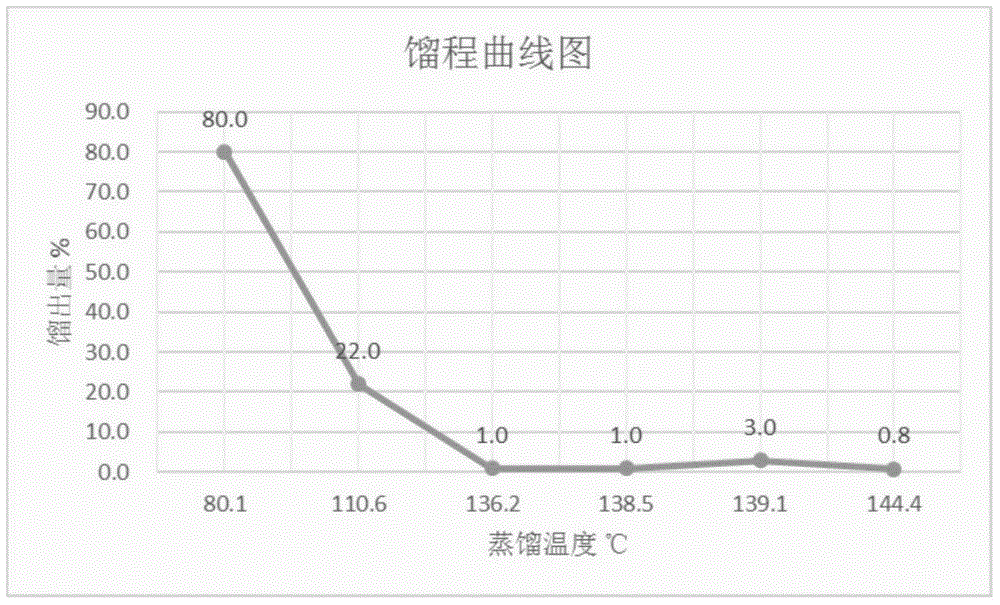

[0049] [Example 1] Apply the coal tar component analyzer of the present invention to measure the content of 5 components in a coal tar product, and draw the distillation range curve, the 5 components are respectively: benzene, toluene, ethylbenzene , p-xylene, meta-xylene and ortho-xylene.

[0050] This embodiment is carried out according to the method for determining the distillation curve curve of the present invention. During the experiment, the temperature of the heating furnace 9 is controlled so that the sample in the distillation bottle 1 is heated up at a rate of 6 ° C / min. After the distillate is distilled , control the heating temperature so that the droplet temperature is controlled at 20°C, the computer automatically counts the distillation range data, and the content inspection report of each component is as follows:

[0051] Content inspection report of each component

[0052]

[0053] The distillation range curve figure of the present embodiment is shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com