Method and device for measuring air permeability of battery diaphragm

A technology for battery separators and testing methods, which is applied to measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problems of expensive testing equipment, complicated operation process, inconvenient maintenance, etc., and achieve simple structure, The effect of simple principle and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

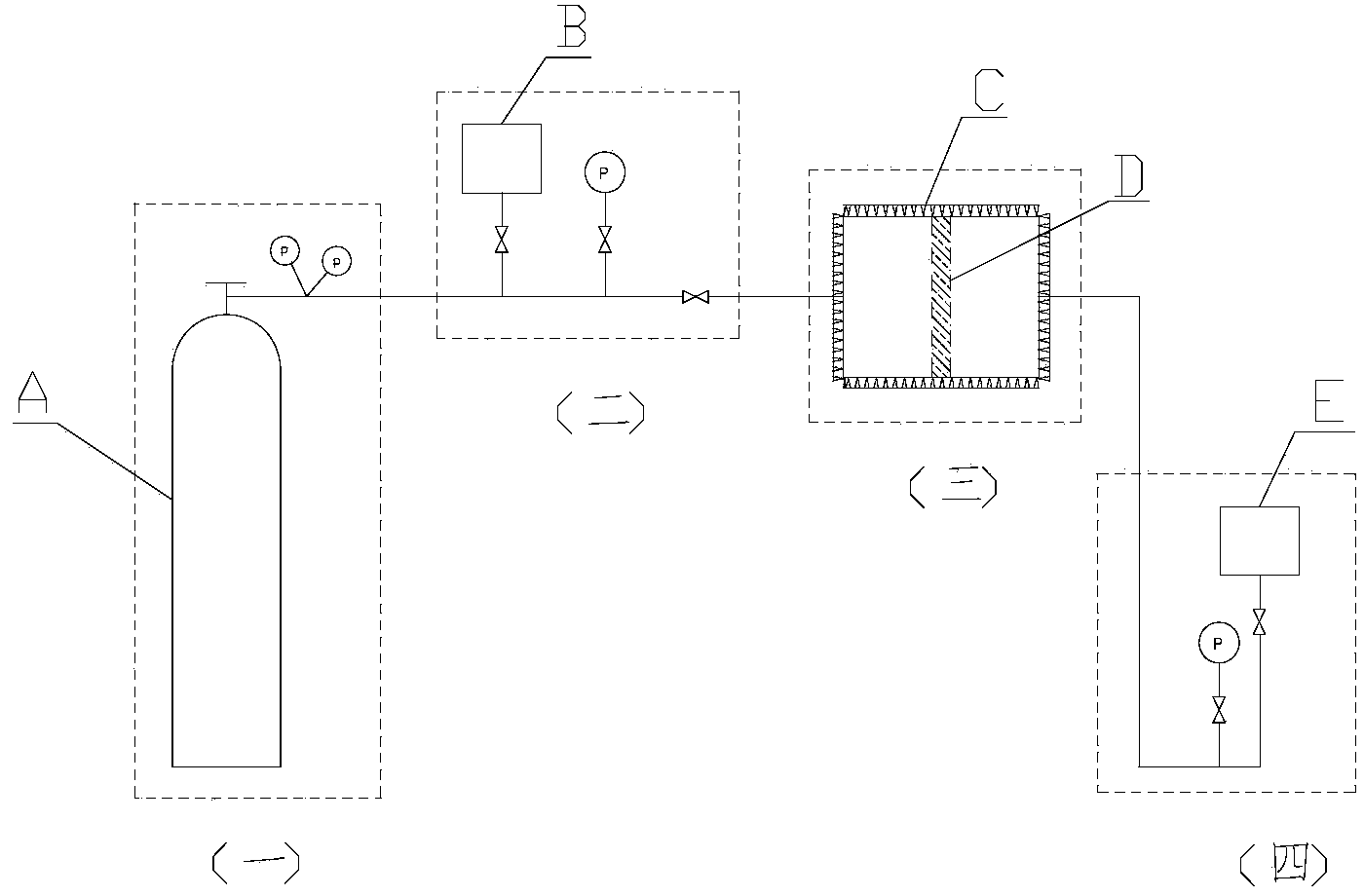

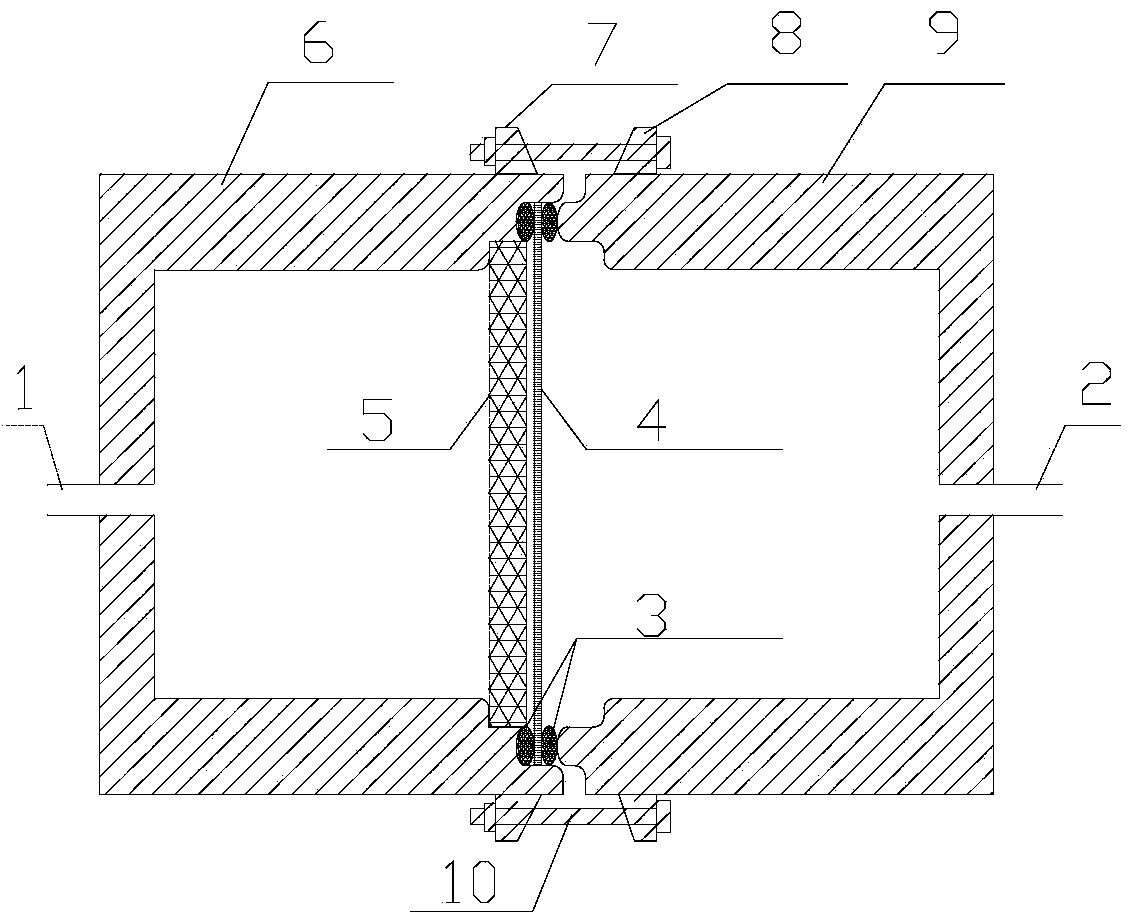

[0022] Such as Figure 1-Figure 2 As shown, the battery diaphragm air permeability test device of the present invention mainly includes: an air supply system (1), a voltage stabilization system (2), a temperature change test system (3), a metering system (4), and an output end of the air supply system (1) It is connected to the voltage stabilizing system (2), the output end of the voltage stabilizing system (2) is connected to the variable temperature testing system (3), and the output end of the variable temperature testing system (3) is connected to the metering system (4), where:

[0023] The test gas is mainly air (oxygen:nitrogen=29:71 according to the volume ratio), and any other types of gases can also be tested. The gas supply system (1) is mainly composed of gas cylinder A and its supporting high and low pressure relief valves and on-off valves.

[0024] The voltage stabilization system (2) is mainly composed of the back pressure valve B and its matching needle valve, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com