Simple low-cost test method

A test method and low-cost technology, applied in the electronic field, can solve the problems of high test cost and complex test method, and achieve the effect of reducing impedance mismatch, simple operation, and avoiding excessive return loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

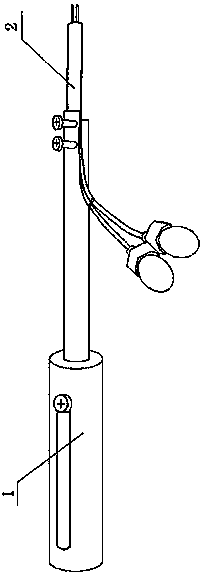

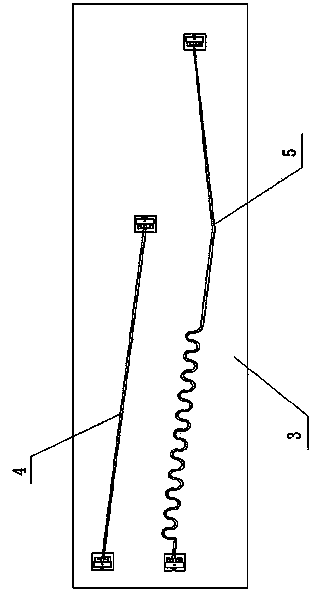

[0019] A simple and low-cost test method, including test fixtures and test boards, two transmission lines to be tested with different lengths are designed on the same level of the test board, named X1 and X2 respectively, as test structures A and B, and the wiring environment Try to be as consistent as possible, where the length of X1 is 11 inches, the length of X2 is 5 inches, and the length difference between X1-X2 is 6 inches. The two ends of the test line are respectively connected to the test points through via holes;

[0020] The S parameters of structure A measured through the transmission line X1 include: IL(A)=11inch transmission line loss + 2 PCB via hole losses + probe loss + uncertain influence of test fixtures;

[0021] The S parameters of structure B measured through the transmission line X2 include: IL(B)=5inch transmission line loss+2 PCB via hole loss+probe loss+test fixture uncertainty influence;

[0022] Calculate the loss formula per inch after the differen...

Embodiment 2

[0024] When designing and testing the transmission line loss of a certain material, such as IT150DA board, design 8-layer board, 4 signal layers, two surface layers and two inner layers, it is necessary to investigate the loss of these four layers of 85 ohm differential transmission lines. Make a test strip next to the motherboard, which can more truly reflect the PCB characteristics of the product. After the PCB processing is completed, take the test strip to the laboratory, use VNA and SMA probes for measurement, and change the PCB working environment, for example, take 3 points between 25 and 75 degrees, 25 degrees, 50 degrees, and 75 degrees. Next do the measurement. After doing differential calculations, the IT150DA sheet is stacked in this structure, and the loss characteristics per inch are obtained in different temperature environments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com