Winding technology of dry-type air reactor

An air-core reactor and winding technology, which is used in the manufacture of inductors/transformers/magnets, circuits, and coils, etc., can solve the problem of accelerating the aging speed of the insulating material of the magnet wire, affecting the safe and stable operation of the power grid, and the winding sealing is not tight, etc. problems, to achieve the effect of increasing anti-aging ability, good sealing, and preventing infiltration

Inactive Publication Date: 2014-09-03

HERONG ELECTRIC

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the summary analysis of the fault problem, we found that the main reason for the reactor burnout is that the winding envelope is not tightly sealed, which is manifested in the small cracks on the inner and outer surfaces of the envelope and the small gaps at the inlet and outlet lines, resulting in a long-term outdoor operation. During operation, rainwater and moisture slowly infiltrate, which accelerates the aging speed of the insulation material of the electromagnetic wire, and finally causes the inter-turn insulation breakdown and short circuit, which causes the product to burn out and affects the safe and stable operation of the power grid. There is no better solution to this problem in technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

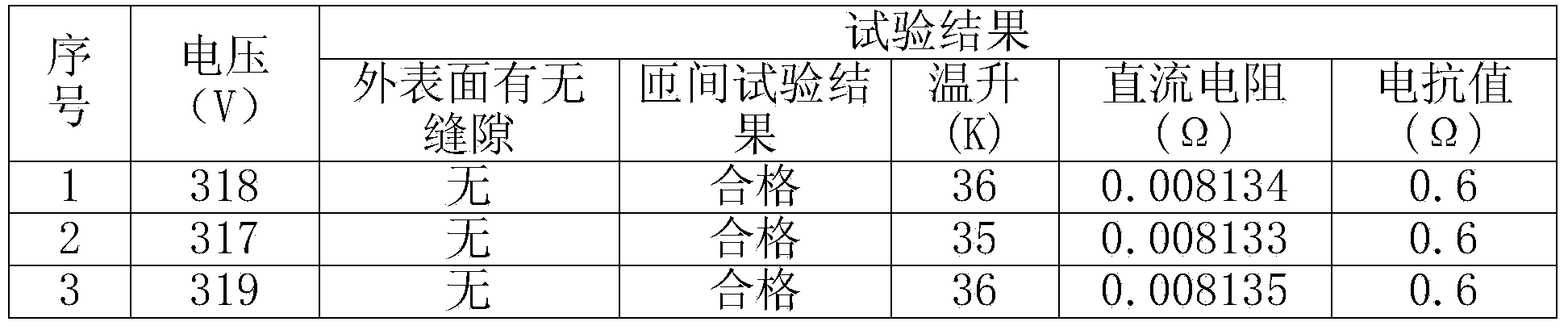

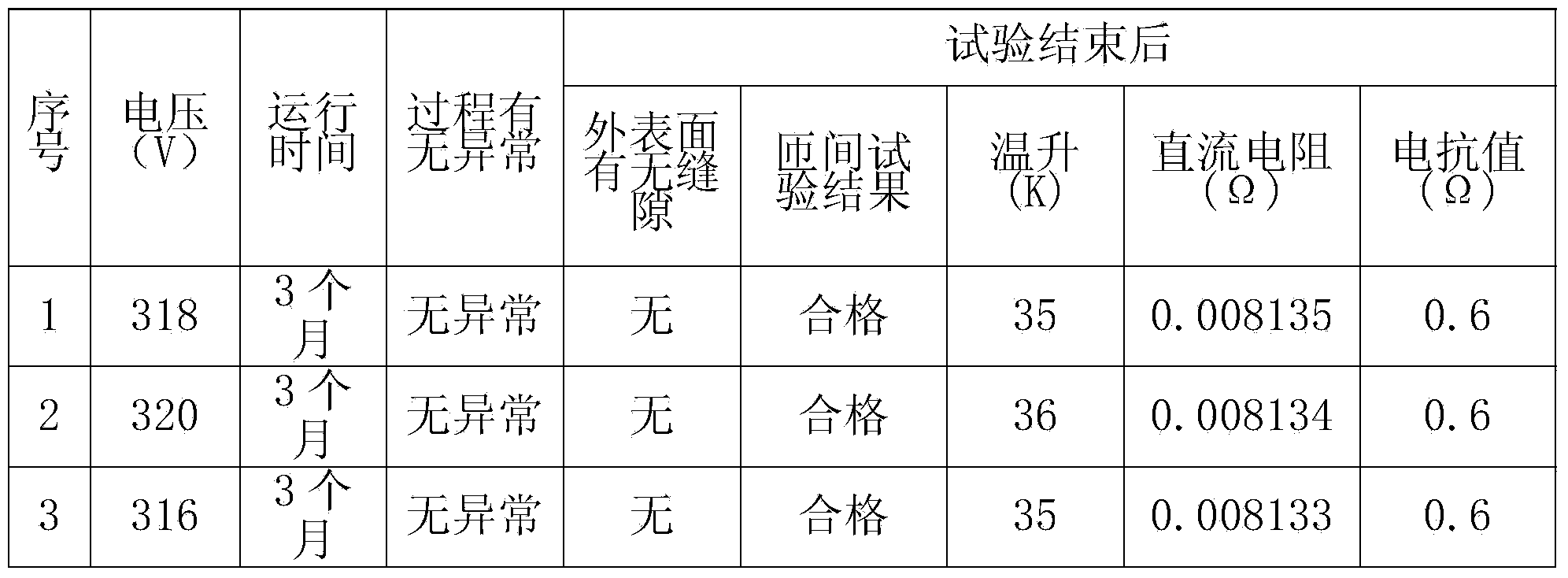

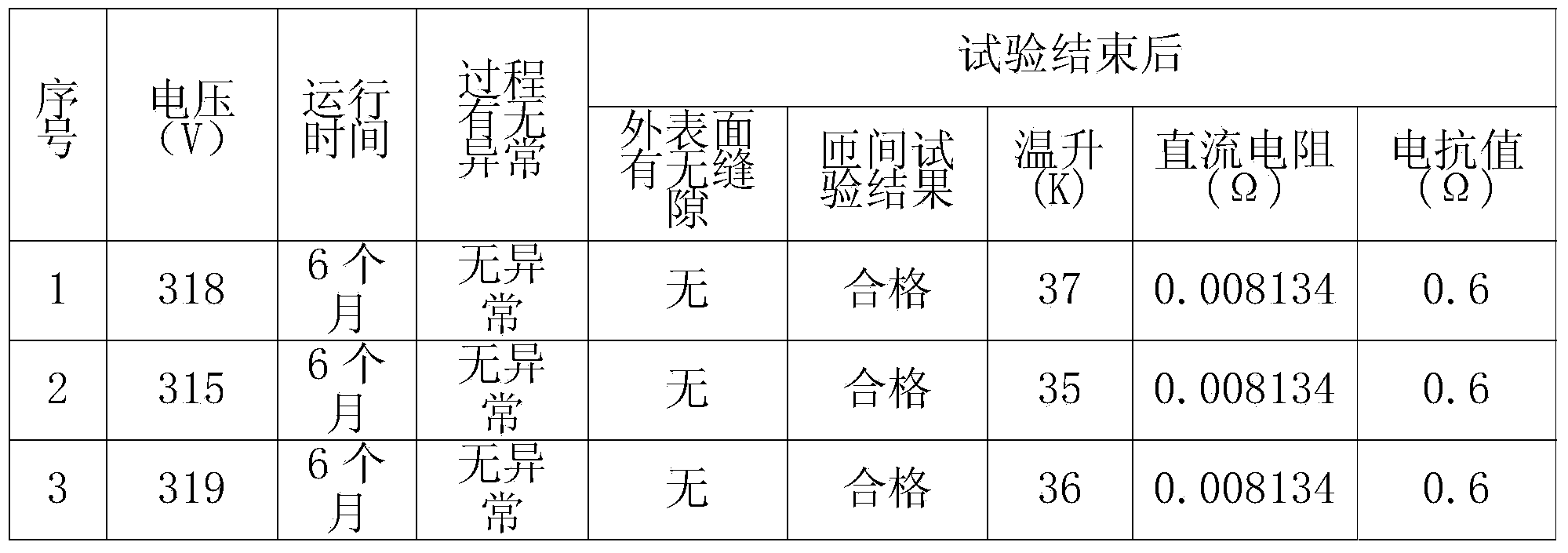

[0038] Take the dry-type air-core reactor CKGKL-167 / 10-5 as an example to carry out the experiment. After the experiment is completed, the test requirements for various data are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a winding technology of a dry-type air reactor. The winding technology comprises the following steps of yarn and insulating material winding, electromagnetic wire winding, plaster filling, epoxy resin mixture brushing, encapsulating outer insulating layer winding, winding solidifying, inlet-outlet wire and lead wire welding, electricity performance testing, insulation varnish painting and silicon rubber insulating paint painting. By means of the winding technology, the insulating level and the damp-proof capacity of the dry-type air reactor can be improved, tiny cracks in the inner surface and the outer surface of an encapsulation of the reactor and small cracks in an inlet-outlet wire are eradicated, the aging speed of a polyester film wrapping an electromagnetic wire is reduced, short circuit caused by turn-insulating breakdown is prevented, product burning is avoided, and the safe and stable operation of a power grid is not affected.

Description

technical field [0001] The invention relates to a production process technology for improving the moisture-proof ability of a dry-type air-core reactor, in particular to a winding process for a dry-type air-core reactor. Background technique [0002] With the acceleration of my country's power grid construction and the expansion of scale, the number of substations is also increasing. Due to its simple structure, convenient and flexible installation, good linear characteristics, stable parameters, low noise, and no oil, dry-type air-core reactors have been favored by users in recent years, and their consumption is increasing year by year, and their capacity and voltage level are also increasing. keep rising. With the increasing use of the grid, there are also various operational failures that come with it. In the summary analysis of the fault problem, we found that the main reason for the reactor burnout is that the winding envelope is not tightly sealed, which is manifeste...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01F41/00H01F41/06H01F17/02H01F41/04H01F41/12

Inventor 刘全峰苗海涛李磊刘娟刘涛

Owner HERONG ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com