Seedling and peanut picking-up and conveying device of peanut harvest

A peanut harvester and conveying device technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve problems such as failure to pick up seedlings, unclean fruit picking, retention, etc. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

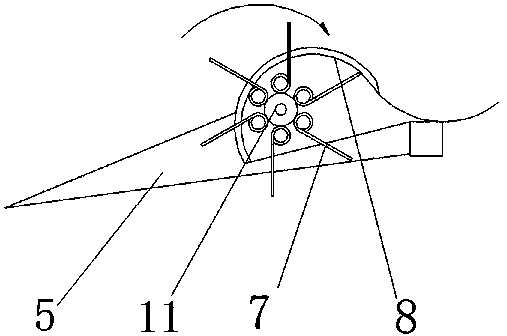

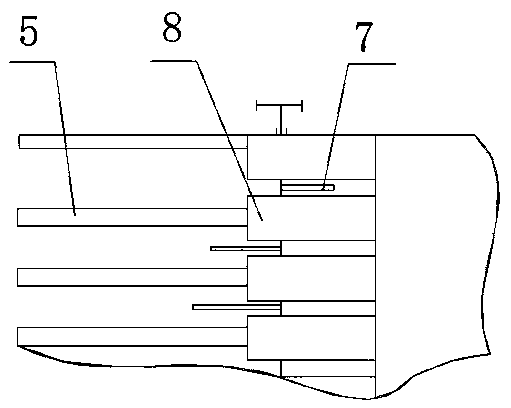

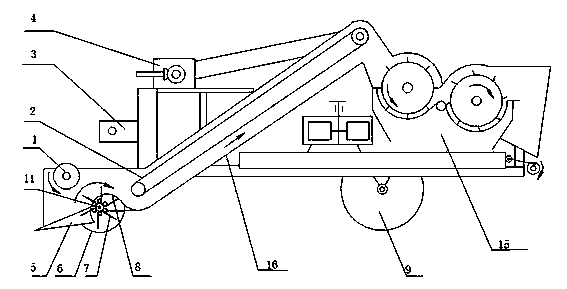

[0018] Such as figure 1 , 2 As shown in and 3, a seedling and fruit picking and conveying device of a peanut harvester includes: a fuselage 15, a traction frame 3, a transmission gearbox 4, and ground wheels 9, wherein the fuselage 15 is supported by the ground wheels 9, and the fuselage 15 is Frame 3 traction, body 15 is powered by transmission gearbox 4, characterized in that: the front end of body 15 is provided with a pick-up conveying device, the pick-up and conveying device consists of feeding roller 1 and fork teeth uniformly distributed on the lower part of feeding roller 1 5. The semicircular arc-shaped partition 8 connected to the rear of the fork 5 and the seedling fruit lifting cylinder 16 are composed. The fork 5 is pointed and triangular, and the arc-shaped partition 8 is provided with uniformly arranged gap grooves. , the inner side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com