Straw cutting, fertilization and seeding all-in-one machine

An all-in-one machine and stalk cutting machine technology, which is applied in the direction of fertilizers and sowing equipment, cutters, harvesters, etc., can solve the problems of uneven sowing, prone to cavitation, and sowing on straw, and achieve fertilization and Uniform sowing depth, high fertilization and sowing quality, and favorable retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

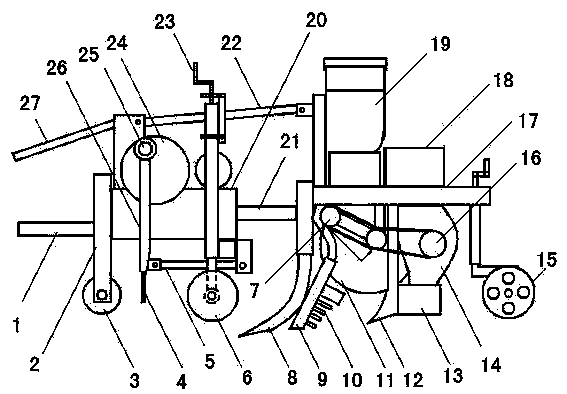

[0021] Such as figure 1 , 2 , 3, 4, 5, and 6, an integrated machine for cutting stalks, fertilizing and seeding, including a stalk cutting machine and a seeder, the draw bar 1 and the upper hanging bar 27 of the stalk cutting machine are respectively connected to the traction shaft and the lifting bar of the tractor, The power shaft 45 of the stalk cutter is connected to the gearbox of the tractor; the rear of the stalk cutter is connected with a fertilizer seeder. The cutting knife 4 of the straw cutter corresponds to the longitudinal positions of the fertilizing plow leg 8 and the sowing plow leg 12 of the fertilizing seeder, that is, the cutting knife 4 cuts the straw into small sections, which is the opening of the fertilizing plow leg 8 and the sowing plow leg 12. Ditch fertilization and sowing to lay the foundation.

[0022] The structure of the straw cutter is:

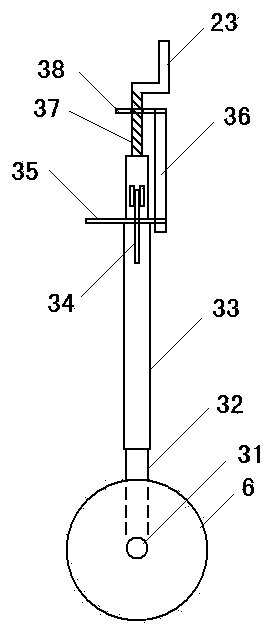

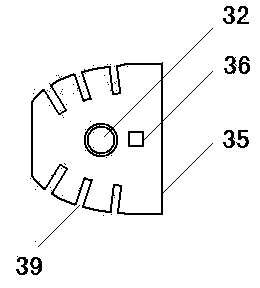

[0023] The bearing 44 is arranged on the stalk cutting frame 20, and a shaft is fixed inside the bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com