Preparation process of melamine foam

A preparation process, melamine technology, applied in the field of new polymer materials, can solve problems such as not involving foaming equipment and parameters, and unclear foaming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

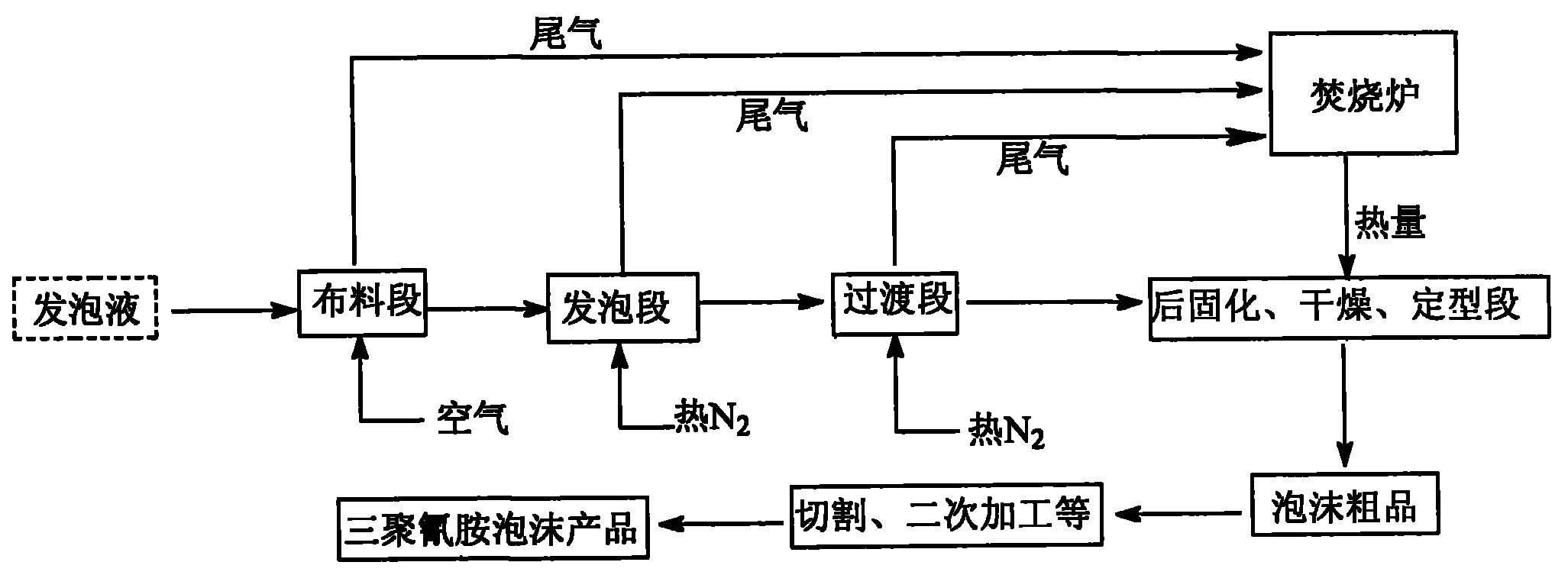

Method used

Image

Examples

Embodiment 1

[0018] Distribute the foaming liquid evenly in the mold, turn on the microwave with 60% power, wait until the foaming liquid is full of the mold, reduce the microwave power to 30%, and adjust the power to 100% after about 2 minutes, 3 minutes The foam is basically formed, after passing through the transition section , enter the drying and shaping section and solidify for 30 minutes to prepare a crude melamine foam product, which is cut to obtain a melamine product.

Embodiment 2

[0020] Distribute the foaming liquid evenly in the mold, turn on the microwave with 20% power, wait until the foaming liquid is full of the mold, adjust the microwave power to 60%, and adjust the power to 100% after 2 minutes of basic crosslinking, 2 minutes The foam is basically formed, and then After passing through the transition section, drying and setting section, curing for 20 minutes, a crude melamine foam product is prepared, and the crude product is cut to obtain a melamine foam product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com