Fiber rod filling corrugated sandwich structure

A sandwich structure and fiber rod technology, which is applied in the field of space debris protection, can solve the problems of arduous spacecraft protection tasks and the difficulty of the protection structure to meet the protection requirements, and achieve the effect of significant protection effect, enhanced overall strength, and reduced speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

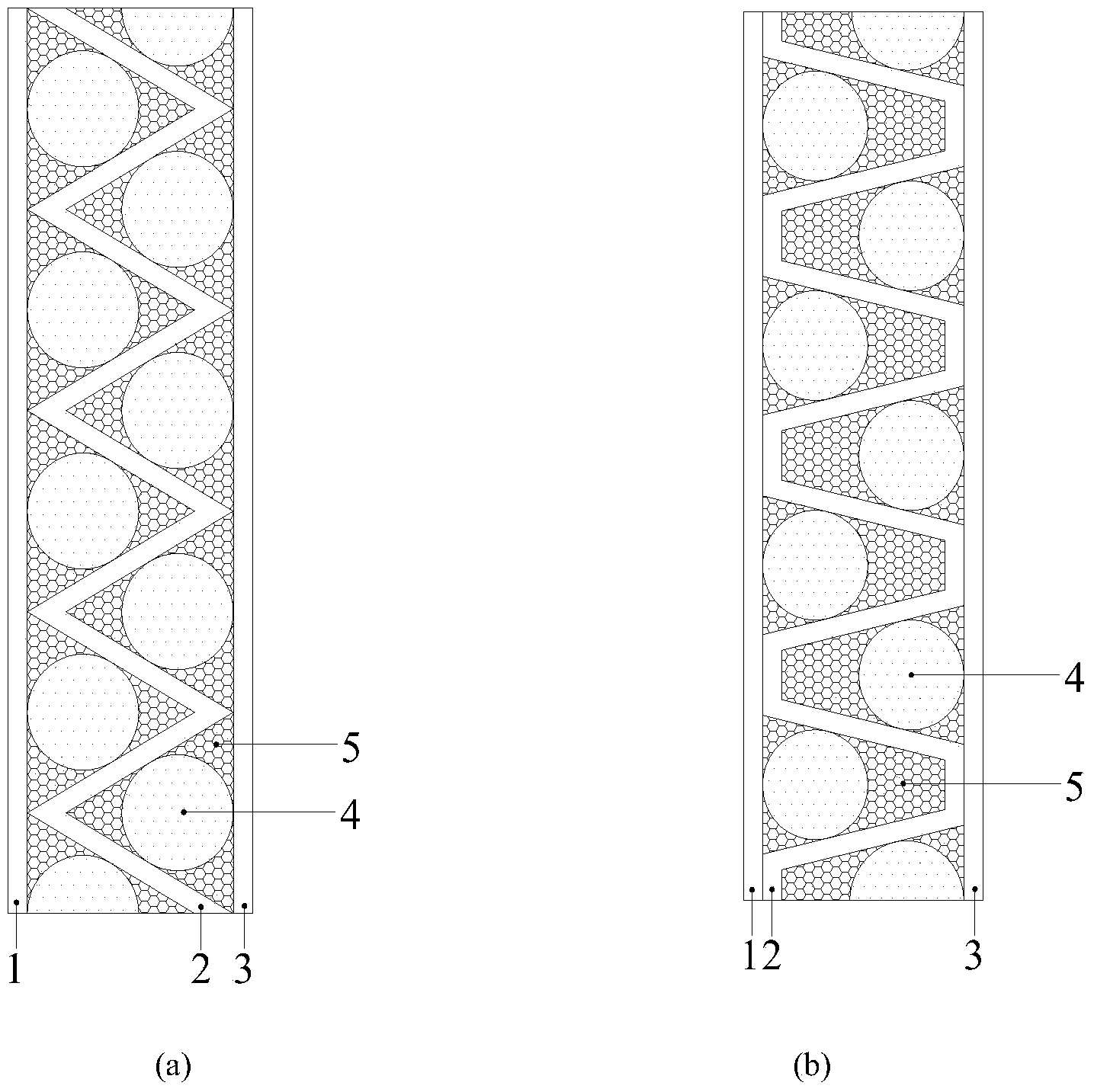

[0026] refer to figure 1 (a), a fiber rod filled corrugated sandwich structure, including an outer plate 1, an inner plate 3, a corrugated plate 2 arranged in the middle of the inner and outer plates, and a corrugated plate arranged in a cavity surrounded by the inner and outer plates and the corrugated plates Cylindrical fiber rod 4 and resin 5 filled in the void. The material of the outer plate 1, the corrugated plate 2 and the inner plate 3 can be light alloy, titanium alloy; the thickness of the outer plate 1, the inner plate 3 and the corrugated plate 2 can be the same; the corrugated shape of the corrugated plate is triangular The material of the fiber rod 4 is carbon fiber; the filling resin 5 is a low-density epoxy resin; the outer plate 1, the corrugated plate 2 and the inner plate 3 are bonded together by a special adhesive, and the fiber rod 4 is inserted into the inner and outer plates and In the cavity surrounded by the corrugated board, the low-density resin 5 i...

Embodiment 2

[0028] refer to figure 1 (b), a fiber rod filled corrugated sandwich structure, comprising an outer flat plate 1, an inner flat plate 3, a corrugated plate 2 arranged in the middle of the inner and outer flat plates, and a corrugated plate arranged in the cavity surrounded by the inner and outer flat plates and the corrugated plates Cylindrical fiber rod 4 and resin 5 filled in the void. The constituent materials of the outer plate 1, the corrugated plate 2 and the inner plate 3 can be light alloys, such as aluminum alloy; the thickness of the outer plate 1, the inner plate 3 and the corrugated plate 2 can be the same; the corrugated shape of the corrugated plate is trapezoidal; the fiber rod 4 is basalt fiber; the filling resin 5 is low-density epoxy resin; the outer plate 1, the corrugated plate 2 and the inner plate 3 are bonded together by a special adhesive, and the fiber rod 4 is inserted into the inner and outer plates In the cavity surrounded by the corrugated board, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com