Unblocking device for cylindrical flat-bottom-shaped reinforced concretebunker

A reinforced concrete, flat-bottomed technology, applied in the field of beneficiation process equipment, can solve the problems of inability to install a pneumatic vibrating hammer, hindering the sliding of ore in the silo, affecting production, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

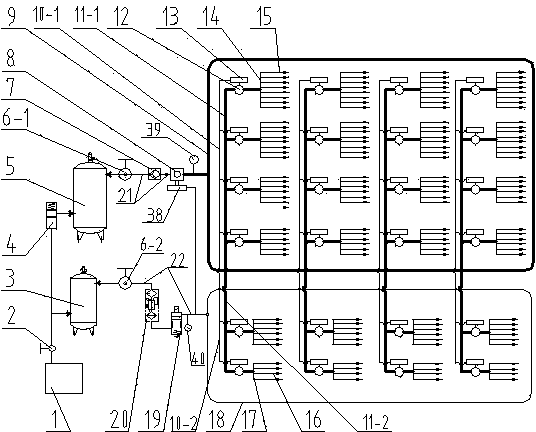

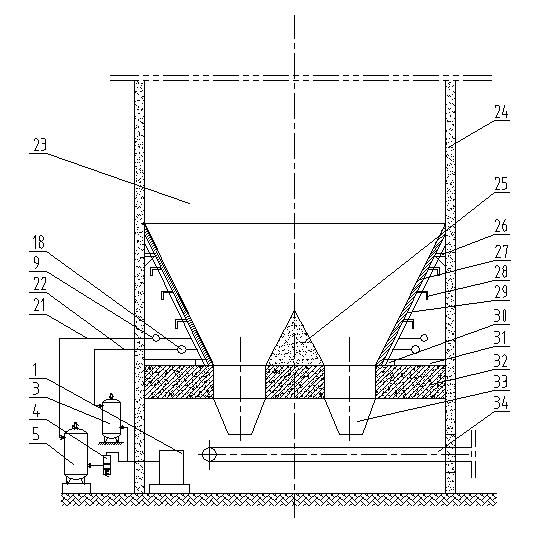

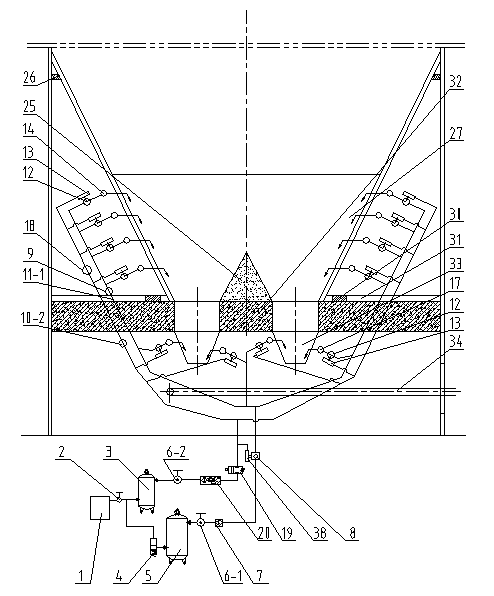

[0021] From Figure 1-Figure 4 It can be seen from the figure that a cylindrical flat-bottomed reinforced concrete silo cleaning device (abbreviated as a silo cleaning device) includes a cylindrical flat-bottomed silo 23, and the silo wall 24 of the silo 23 is round. Cylindrical, the bottom of the silo 23 is provided with a silo flat bottom 32, four discharge holes are evenly distributed on the circumference of the silo flat bottom 32, and a belt conveyor 34 is arranged below each discharge hole; its characteristics Yes: The unclogging device of the cylindrical flat-bottomed reinforced concrete silo also includes air compressor 1, manual ball valve Ⅰ2, air storage tank Ⅰ3 (that is, the air storage tank for control), manual ball valve Ⅱ6-2, and the minimum pressure maintaining valve 4. Air storage tank Ⅱ5 (i.e. air storage tank for flow aid), manual ball valve Ⅲ6-1, left junction box 37, right junction box 35, electric control box 36, pneumatic flow aid device, and pneumatic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com