Plate glass melting furnace clarification portion stepped arch top

A flat glass, stepped technology, used in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of large space for clarifying section, large heat dissipation area, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

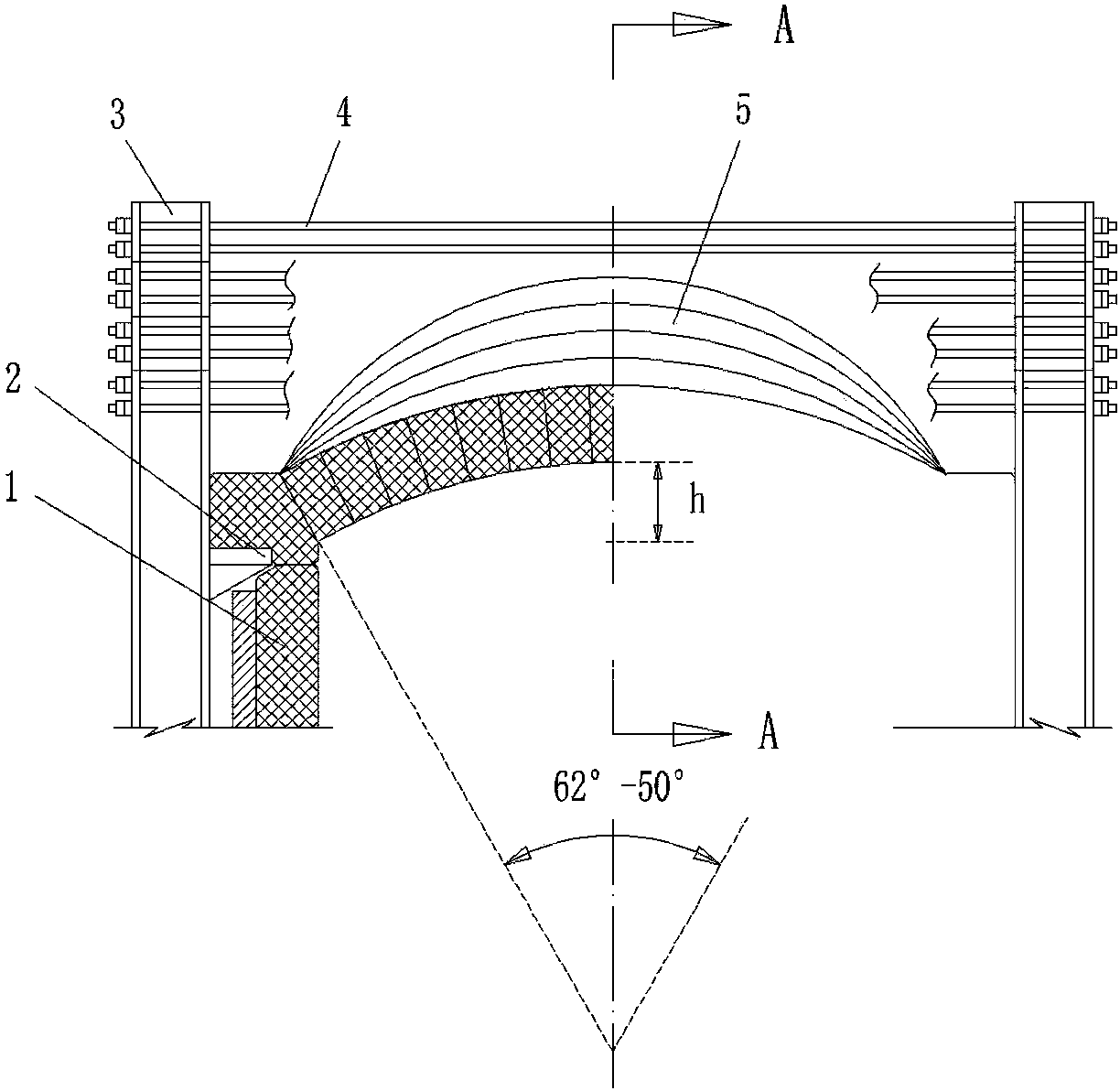

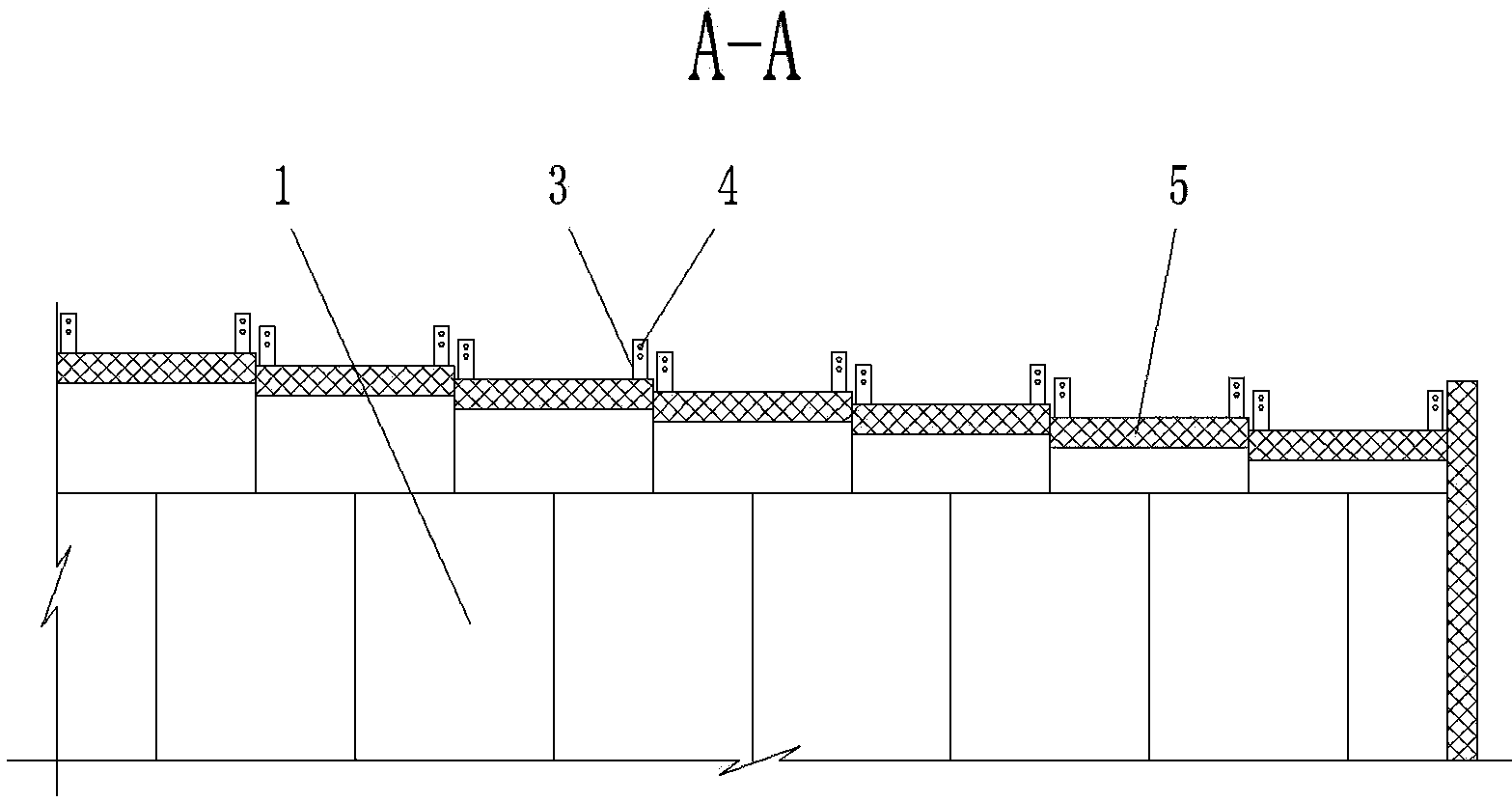

[0012] like figure 1 , figure 2 As shown, a stepped roof of the clarification part of a flat glass melting furnace, which includes: parapets 1 on both sides of the clarification part of the melting furnace, steel columns 3 on the outside of the parapet, roof supports 2 and roof tie rods 4 set on the steel columns , which is characterized by a set of arc-shaped arches 5 with successively decreasing central angles along the parapets on both sides, so that the vault height h of the arches decreases successively in a stepped shape, and the two ends of the arches are connected to the parapets through the arches .

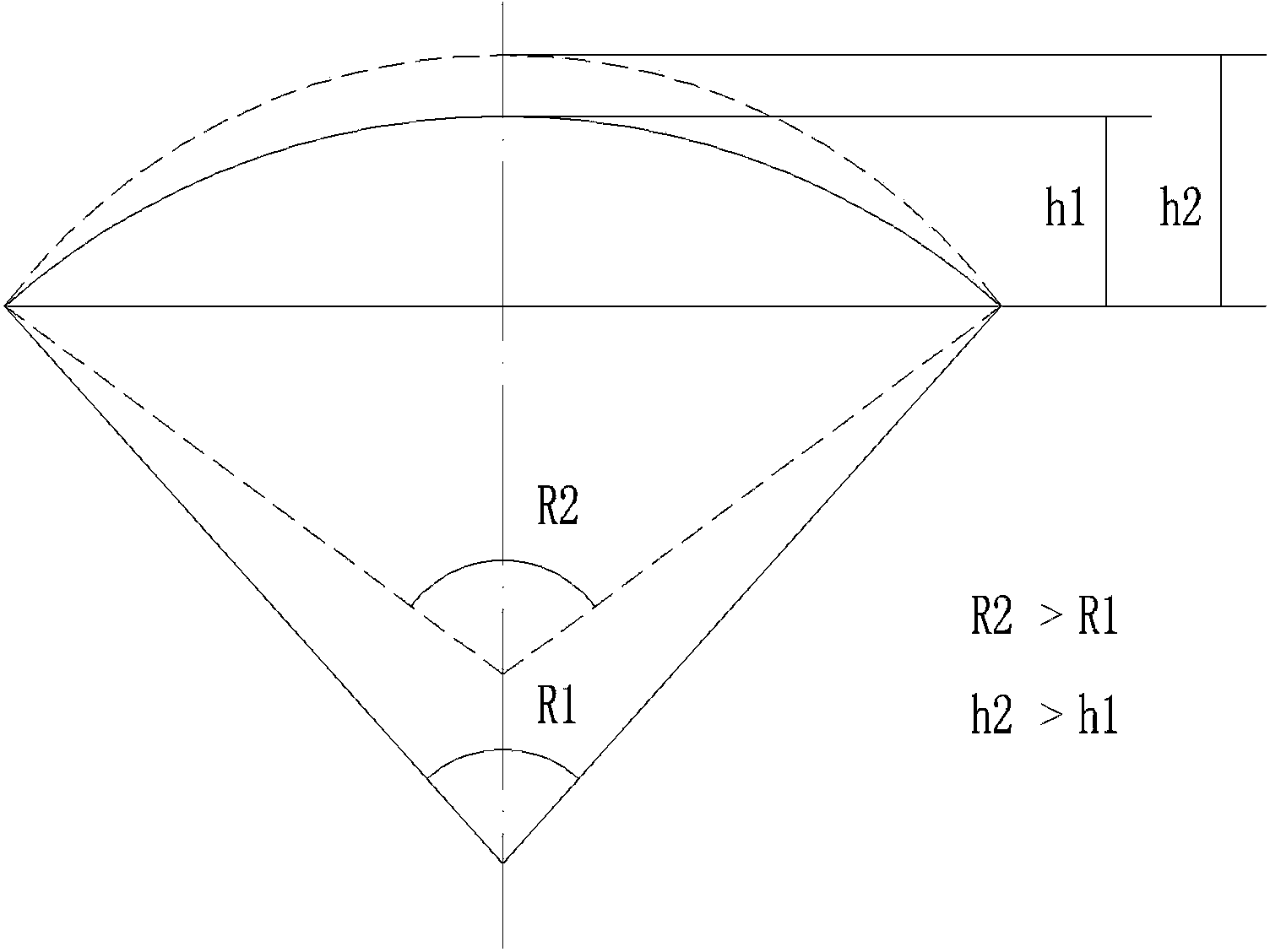

[0013] The described central angle is the angle of the apex on the center of the circle, and the two sides of the angle are two radii of the same garden, such as image 3 As shown, when the chord length of the arc is constant, the chord height h of the arc is proportional to the change of the central angle R, and the stepped crown of the present invention, the width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com