Joint structure and construction method of hybrid connected-wall steel column and non-energy-dissipating beam

A technology for connecting nodes and connecting limb walls, applied in the direction of walls, building components, building structures, etc., to achieve the effect of reliable connection relationship, easy repair, and ensure the quality of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

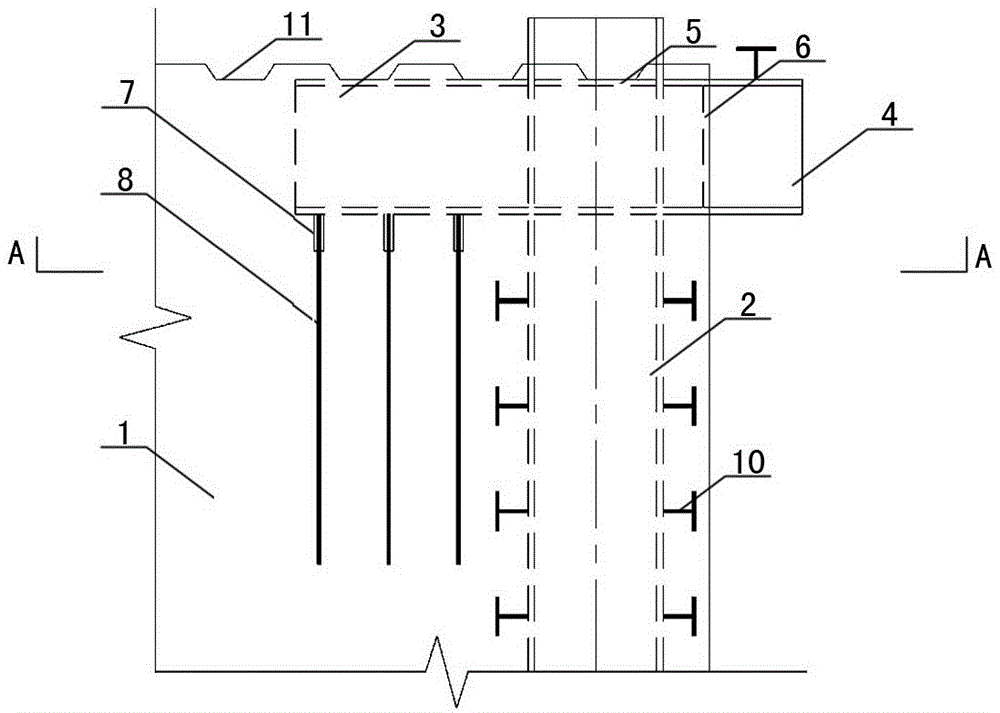

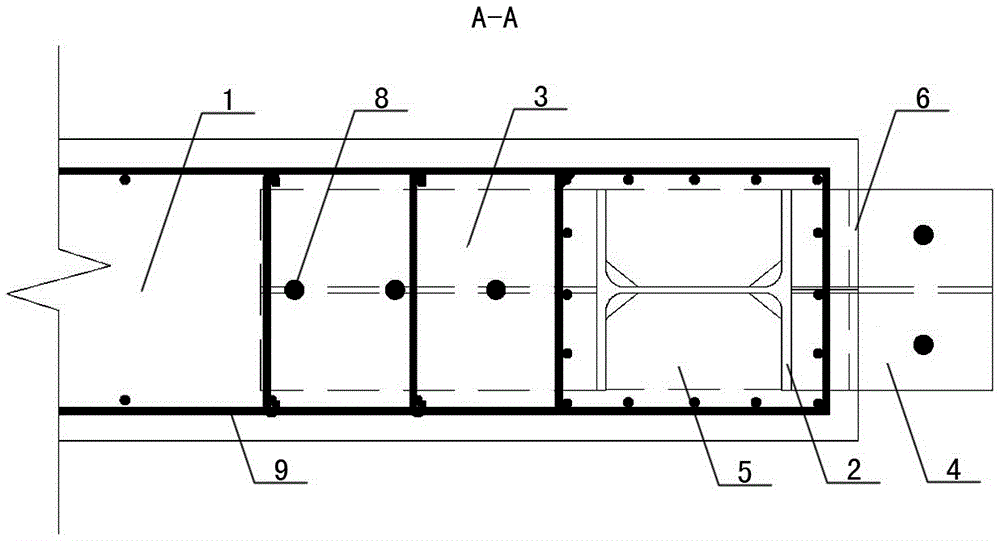

[0035] Examples see figure 1 As shown, the connection node structure between the steel column of the hybrid connected limb wall and the short beam of non-energy dissipating steel includes the steel skeleton 9 poured in the composite connected limb wall 1 and the steel column 2 located at the inner end of the composite connected limb wall 1 , and a non-energy-dissipating steel short beam 4 connected to the outside of the steel column 2, a transverse stiffener 5 is fixed on the steel column 2, and a shear stud is fixed on the steel column 2 and the short non-energy-dissipating steel beam 4 10. One or more of the upper, lower, left, and right sides of the mixed limb wall 1 is rough or has key grooves in the horizontal direction.

[0036] Both the upper and lower ends of the shaped steel column 2 protrude from the mixed limb wall 1, and the upper part of the shaped steel column 2 is fixed along the length direction of the mixed limb wall 1. One end of the beam 4 connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com