Photovoltaic element and manufacturing method thereof

A photovoltaic element and protective layer technology, applied in the field of photovoltaic elements and its manufacturing, can solve the problem of increasing the reflectivity of the anti-reflection layer and achieve the effect of suppressing the PID effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

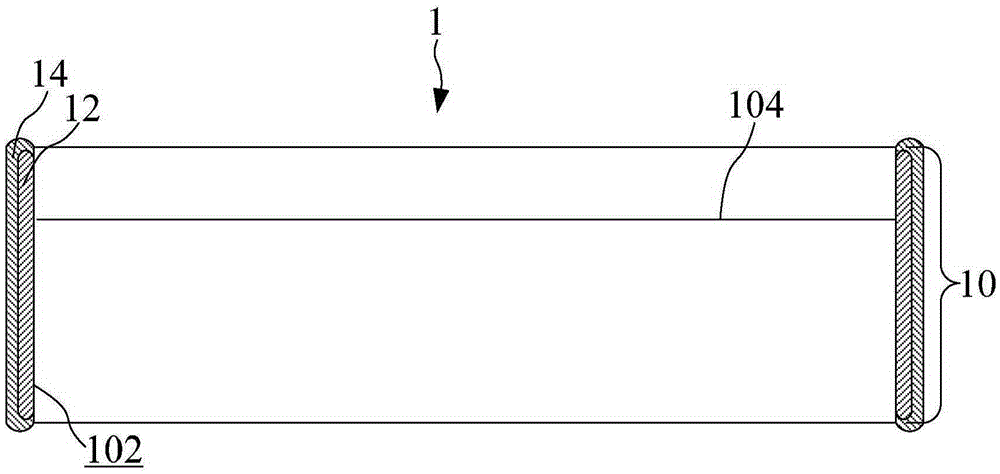

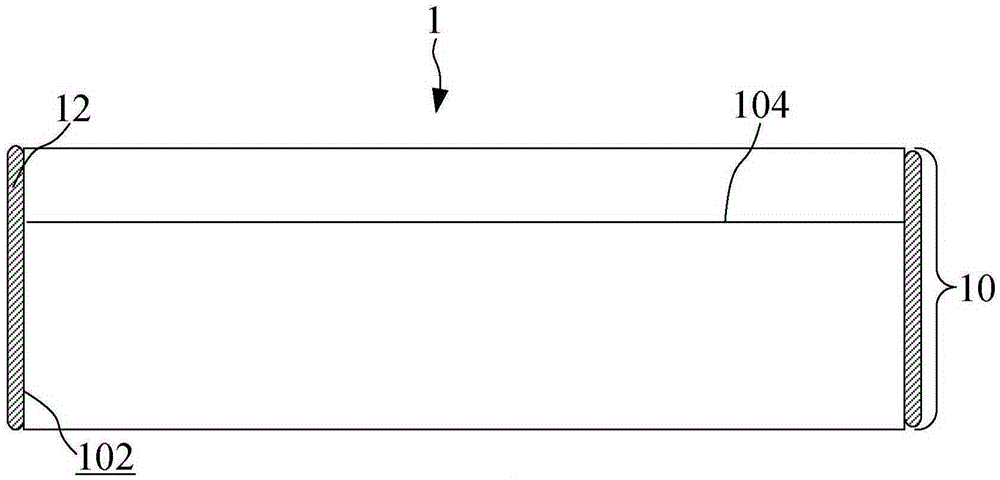

[0019] see figure 1 , figure 1 A photovoltaic element 1 according to a preferred embodiment of the present invention is schematically shown in a cross-sectional view.

[0020] Such as figure 1 As shown, the photovoltaic element 1 of the present invention includes a semiconductor structure combination 10 and a first protective layer 12 . The semiconductor structure assembly 10 has multiple side surfaces 102 and includes p-n junctions, n-p junctions, p-i-n junctions, n-i-p junctions, double junctions, multiple junctions, or other types of junctions. That is to say, the photovoltaic element 1 of the present invention can be a monocrystalline silicon photovoltaic element, a quasi-monocrystalline silicon photovoltaic element, a polycrystalline silicon photovoltaic element, a gallium arsenide-based photovoltaic element, an amorphous silicon thin film photovoltaic element, a microcrystalline silicon (μ-Si ) thin film photovoltaic elements, cadmium sulfide (CdS) thin film photovolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com