A kind of preparation method of crystalline silicon solar cell

A technology of solar cells and crystalline silicon, applied in the field of solar energy, can solve the problems of increasing the cost of solar modules, limited selection of inverters, adverse effects on system efficiency, etc. Simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a crystalline silicon solar cell, taking the preparation of an existing conventional cell as an example, comprises the following steps:

[0030] (1) Texturing, diffusion, and edge etching of the silicon wafer;

[0031] (2) Form a silicon dioxide dielectric film on the light-receiving surface of the silicon wafer by PECVD, and the silicon oxide thickness is 2.2nm;

[0032] (3) Plating anti-reflection film, printing electrodes by screen printing, and sintering to form ohmic contact;

[0033] (4) Using conventional packaging materials, the battery strings are interconnected, packaged, and laminated to make components.

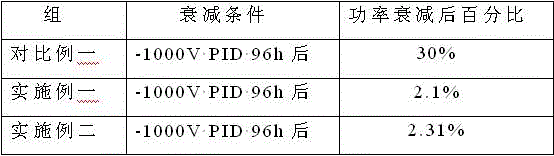

Embodiment 2

[0035] A method for preparing a crystalline silicon solar cell, taking the preparation of an existing conventional cell as an example, comprises the following steps:

[0036] (1) Texturing, diffusion, and edge etching of the silicon wafer;

[0037] (2) Form a silicon dioxide dielectric film on both sides of the silicon wafer by PECVD, and the silicon dioxide thickness is 2.2nm;

[0038] (3) Plating anti-reflection film, printing electrodes by screen printing, and sintering to form ohmic contact;

[0039] (4) Using battery sheets with the same efficiency level as in Example 1 and conventional packaging materials, the battery strings are interconnected, packaged, and laminated to make components.

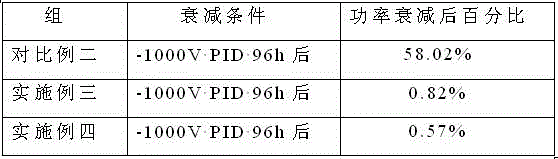

Embodiment 3

[0050] A method for preparing a crystalline silicon solar cell, taking the preparation of a MWT cell as an example, comprises the following steps:

[0051] (1) Texturing, diffusion, and edge etching of the silicon wafer;

[0052] (2) Form a silicon dioxide dielectric film on the light-receiving surface of the silicon wafer by PECVD, and the silicon oxide thickness is 2.5nm;

[0053] (3) Plating anti-reflection film, drilling, printing electrodes by screen printing, and sintering to form ohmic contact;

[0054] (4) Using conventional packaging materials, the battery strings are interconnected, packaged, and laminated to make components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com