Metal guardrail coating with high weather resistance and stain resistance, and preparation method thereof

A highly weather-resistant and stain-resistant technology, used in anti-fouling/underwater coatings, polyester coatings, metal-free paints, etc. Performance, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

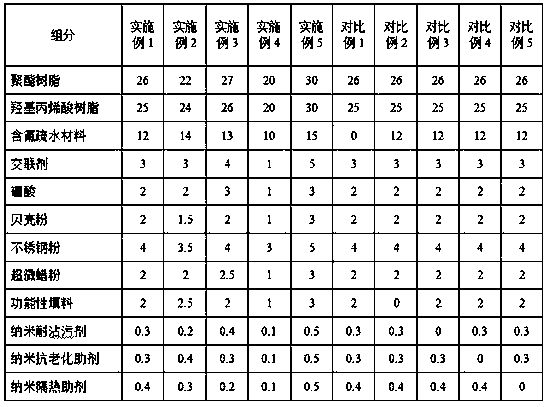

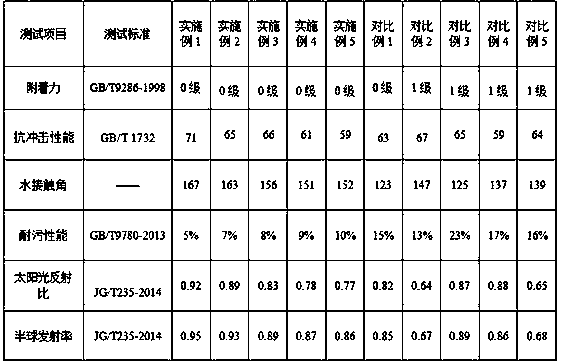

Embodiment 1-5 and comparative example 1-5

[0027] The raw materials used are all commercially available, wherein:

[0028] Polyester resin, Luoyang Lesen Petrochemical New Material Co., Ltd. polyester resin 8690A;

[0029] Hydroxy acrylic resin, Kemic chemical hydroxy acrylic resin KR9250;

[0030] Cross-linking agent, Zigong Tianlong Chemical Co., Ltd. cross-linking agent TAC;

[0031] Boric acid, Zhengzhou Del Boron Chemical Co., Ltd. customized 200 mesh boric acid;

[0032] Shell powder, Martinet ecological shell powder;

[0033] Stainless steel powder, ultrafine stainless steel powder from Feida Metallurgical Powder Co., Ltd.;

[0034] Superfine wax powder, Clariant Chemical Co., Ltd. 3920F;

[0035] Functional filler, Zhongke Huaxing New Material Co., Ltd. hollow glass microspheres-C20;

[0036] The nano-scale anti-fouling agent is nano-scale modified fumed silica, Kane Chemical R974;

[0037] Nano anti-aging additives, nano TiO 2 ;

[0038] The nano-insulation additive is nano-alumina, DK410-2 from Beijin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com