A high-efficiency special heavy-duty anti-corrosion coating

A heavy-duty anti-corrosion and special technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, conductive coatings, etc., can solve problems such as waterproof, anti-mildew, poor bactericidal effect, harmful anti-corrosion coatings, high VOC emissions, etc., to achieve construction safety Convenient, beneficial to human health and environmental sanitation, low VOC emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

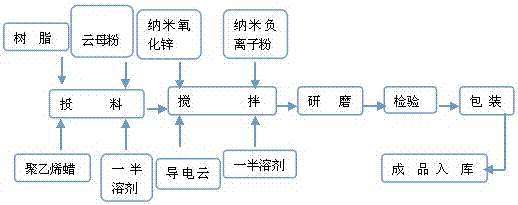

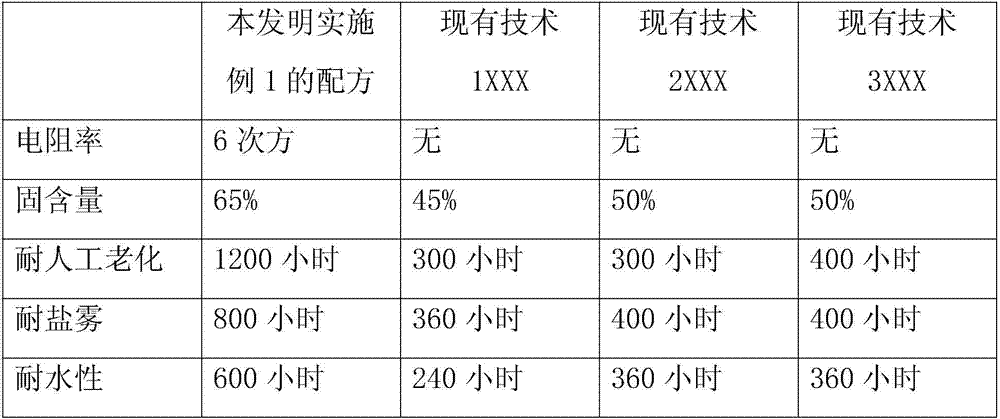

[0027] According to modified epoxy resin: conductive mica powder: composite nano-anion: nano-zinc oxide: mica powder: polyethylene wax: butyl acetate: n-butanol = 50:25:5:10:20:3:15:10 , take by weighing 50kg of modified epoxy resin, 25kg of conductive mica powder, 5kg of composite nano-anion powder, 10kg of nano-zinc oxide, 20kg of mica powder, 3kg of polyethylene wax, 15kg of butyl acetate, and 10kg of n-butanol for subsequent use.

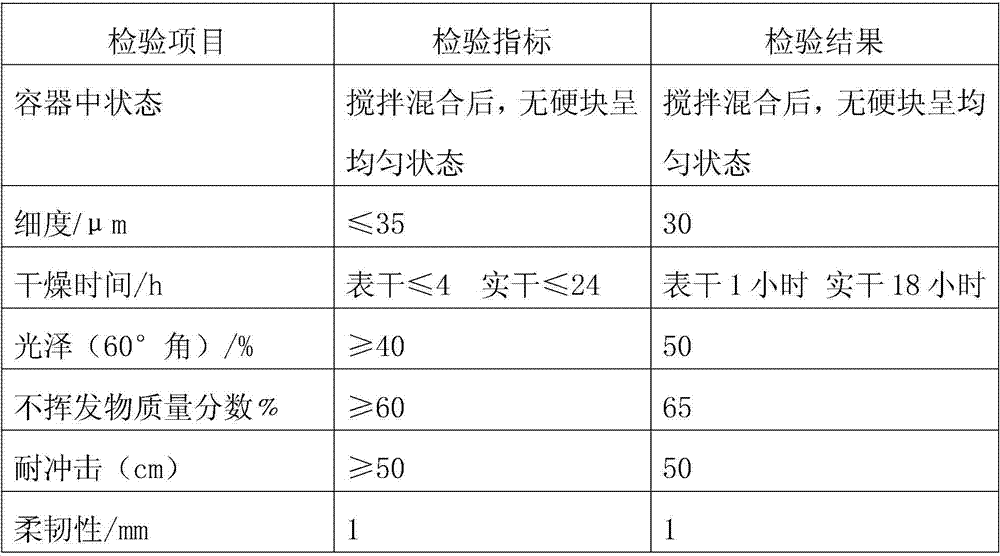

[0028] ①Add modified epoxy resin, half of n-butanol, half of butyl acetate, polyethylene wax, and mica powder into the stirring tank of the high-speed disperser according to the process formula, and stir and mix evenly; ②Add nano-zinc oxide, nano-anions, Conductive mica powder, the other half of n-butanol, the other half of butyl acetate, etc. are dispersed and mixed evenly; ③Pumped to a sand mill for further grinding, and sampling inspection until the fineness meets the standard requirements; ④Packed through a vibrating sieve; ⑤The finished prod...

Embodiment 2

[0033] Modified epoxy resin: conductive mica powder: composite nano-anion: nano-zinc oxide: mica powder: polyethylene wax: butyl acetate: n-butanol = 55:35:5:10:20:5:20:15 , take by weighing 55kg of modified epoxy resin, 35kg of conductive mica powder, 5kg of composite nano-anion, 10kg of nano-zinc oxide, 20kg of mica powder, 5kg of polyethylene wax, 20kg of butyl acetate, and 15kg of n-butanol, and set aside.

[0034] ①Put modified epoxy resin, half of n-butanol, half of butyl acetate, polyethylene wax, and mica powder raw and auxiliary materials into the stirring tank of the high-speed disperser according to the process formula, and stir and mix evenly; ②Add nano-zinc oxide, Nano negative ions, conductive mica powder, the other half of n-butanol, the other half of butyl acetate, etc. are dispersed and mixed evenly; ③Pumped to a sand mill for further grinding, sampling inspection until the fineness meets the standard requirements; ④Packed through a vibrating sieve ; ⑤ Finishe...

Embodiment 3

[0039] Modified epoxy resin: conductive mica powder: composite nano-anion: nano-zinc oxide: mica powder: polyethylene wax: butyl acetate: n-butanol = 70:35:5:10:15:6:15:10 , take by weighing 70kg of modified epoxy resin, 35kg of conductive mica powder, 5kg of composite nano-anion, 10kg of nano-zinc oxide, 15kg of mica powder, 6kg of polyethylene wax, 15kg of butyl acetate, and 10kg of n-butanol for subsequent use.

[0040] ①Put modified epoxy resin, half of n-butanol, half of butyl acetate, polyethylene wax, and mica powder raw and auxiliary materials into the stirring tank of the high-speed disperser according to the process formula, and stir and mix evenly; ②Add nano-zinc oxide, Nano negative ions, conductive mica powder, the other half of n-butanol, the other half of butyl acetate, etc. are dispersed and mixed evenly; ③Pumped to a sand mill for further grinding, sampling inspection until the fineness meets the standard requirements; ④Packed through a vibrating sieve ; ⑤ Fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com