Photovoltaic module frame and material thereof, and photovoltaic module

A photovoltaic module and frame technology, applied in photovoltaic modules, photovoltaic power generation, electrical components, etc., can solve problems affecting the power generation of photovoltaic modules, achieve light weight, reduce transportation costs, and increase output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

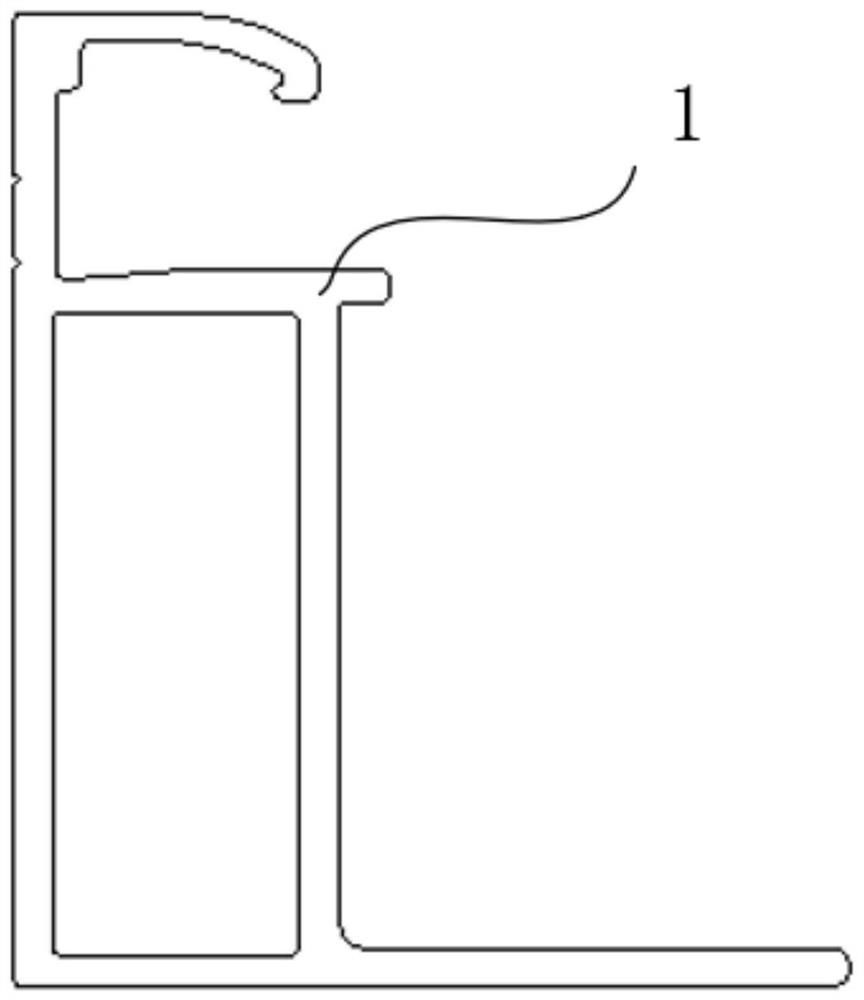

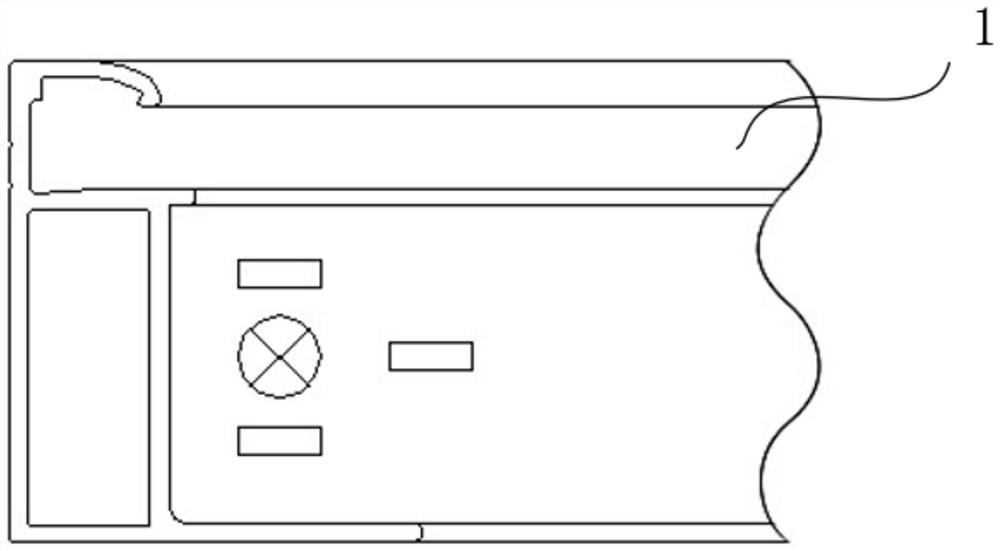

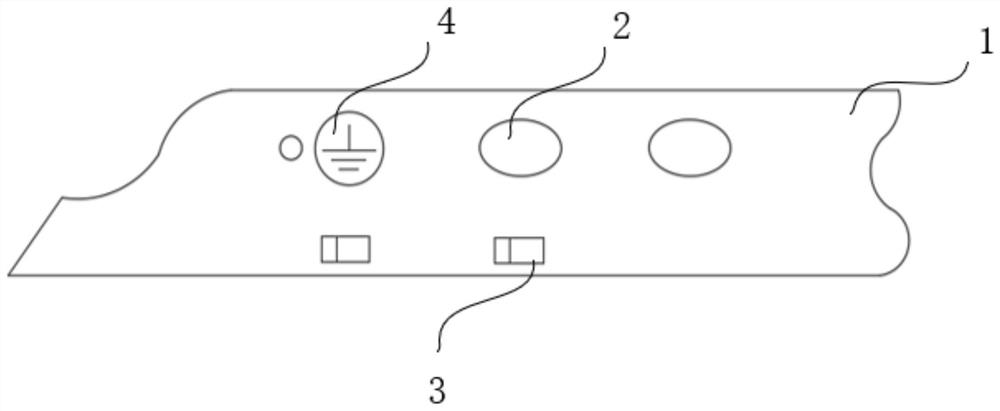

Image

Examples

Embodiment 1

[0045] In terms of mass percentage, the photovoltaic module frame material provided by the embodiment of the present invention includes: 64% by mass of polyamide resin, 32% by mass of glass fiber, 2.5% by mass of triethylhexyl phosphoric acid, 2.5% by mass of triethylhexyl phosphoric acid, 0.8% polycarbodiimide, 0.6% by mass of o-hydroxybenzophenone, and 0.1% by mass of antimony trioxide. Put the above materials into the twin-screw extruder in sequence, and extrude the photovoltaic module frame material through the twin-screw extruder, and then heat and melt the above-mentioned photovoltaic module frame material through the twin-screw extruder, The extrusion die head is cold cut and shaped to obtain the frame of the photovoltaic module provided by the embodiment of the present invention. The continuous production of the frame of the photovoltaic module can be realized by continuously adding each component of the above-mentioned mass ratio into the twin-screw extruder, and the ...

Embodiment 2

[0047] Different from Example 1, in terms of mass percentage, the photovoltaic module frame material provided by the embodiment of the present invention includes: 72% by mass of polypropylene, 24% by mass of carbon fiber, 2.5% by mass of twelve A mixture of sodium alkyl sulfate and methyl amyl alcohol (the mass ratio of sodium lauryl sulfate and methyl amyl alcohol is 1:1), and the mass percentage is 0.8% of N,N-bis(2,6-diiso Propylphenyl) carbodiimide, a mixture of benzotriazole and salicylate in a mass percentage of 0.6% (the mass ratio of benzotriazole and salicylate is 1:1), and a mass percentage of 0.1 % magnesium hydroxide. The performance parameters of the photovoltaic module frame material prepared according to the mass ratio relationship of each component provided in the embodiment of the present invention are shown in Table 1.

Embodiment 3

[0049] Different from Example 1, in terms of mass percentage, the photovoltaic module frame material provided by the embodiment of the present invention includes: polyethylene terephthalate with a mass percentage of 65%, boron fiber with a mass percentage of 28.7%, The mass percentage is the mixture of polyacrylamide, guar gum and fatty acid polyethylene glycol ester of 4% (the mass ratio of polyacrylamide, guar gum and fatty acid polyethylene glycol ester is 1:1:1), mass percentage A mixture of 1.1% polycarbodiimide UN-03 and N,N-bis(2,6-diisopropylphenyl)carbodiimide (polycarbodiimide UN-03 and N,N- The mass ratio of bis(2,6-diisopropylphenyl)carbodiimide is 1:1), triazine with a mass percentage of 0.8%, and aluminum hydroxide with a mass percentage of 0.4%. The performance parameters of the photovoltaic module frame material prepared according to the mass ratio relationship of each component provided in the embodiment of the present invention are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com