Low-resistance wear-resisting plastic-steel composite cable conduit with middle bonding layer

A composite cable and bonding layer technology, which is applied to the installation of cables in ground conduits, the installation of cables in underground pipes, and the installation of cables, can solve the requirements of cable life, the disadvantage of insulation and anti-aging, and the increase of cable pulling machines. Power and heat are not easy to dissipate, etc., to achieve the effect of increased friction, small friction surface and small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

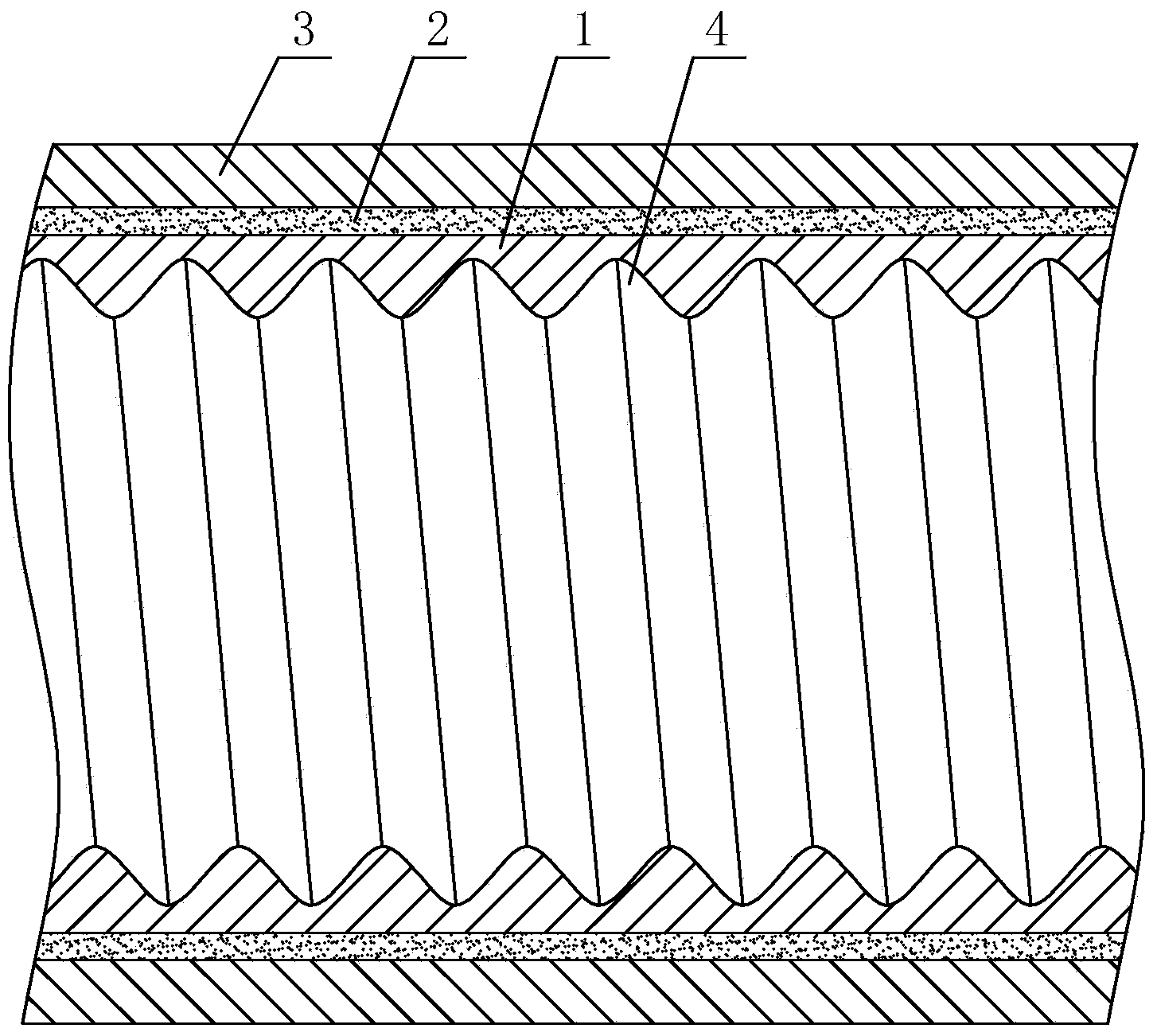

[0014] like figure 1 As shown, a low-resistance wear-resistant plastic-steel composite cable conduit with an intermediate adhesive layer includes an inner tube 1, the inner surface of the inner tube 1 is continuously provided with internal thread grooves 4 along the axial direction of the inner tube, and the outer surface of the inner tube 1 A layer of intermediate bonding layer 2 is coated along the axial direction of the inner tube 1 , and a glass steel pipe 3 formed by winding resin-soaked glass filaments is arranged on the outer surface of the intermediate bonding layer 2 .

[0015] The inner tube 1 is a thermoplastic tube.

[0016] The composite cable guide of the present invention has a reasonable structural design, and the outer surface of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com