Coreless type megawatt superconducting motor system

A superconducting motor, ironless technology, applied in the usage of superconductor elements, electrical components, electromechanical devices, etc., can solve problems such as affecting the normal operation of the system, increasing the quality of the system, discounting the excitation effect, etc., to solve the mechanical stress and support. Protection problems, ensuring low temperature environment, the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

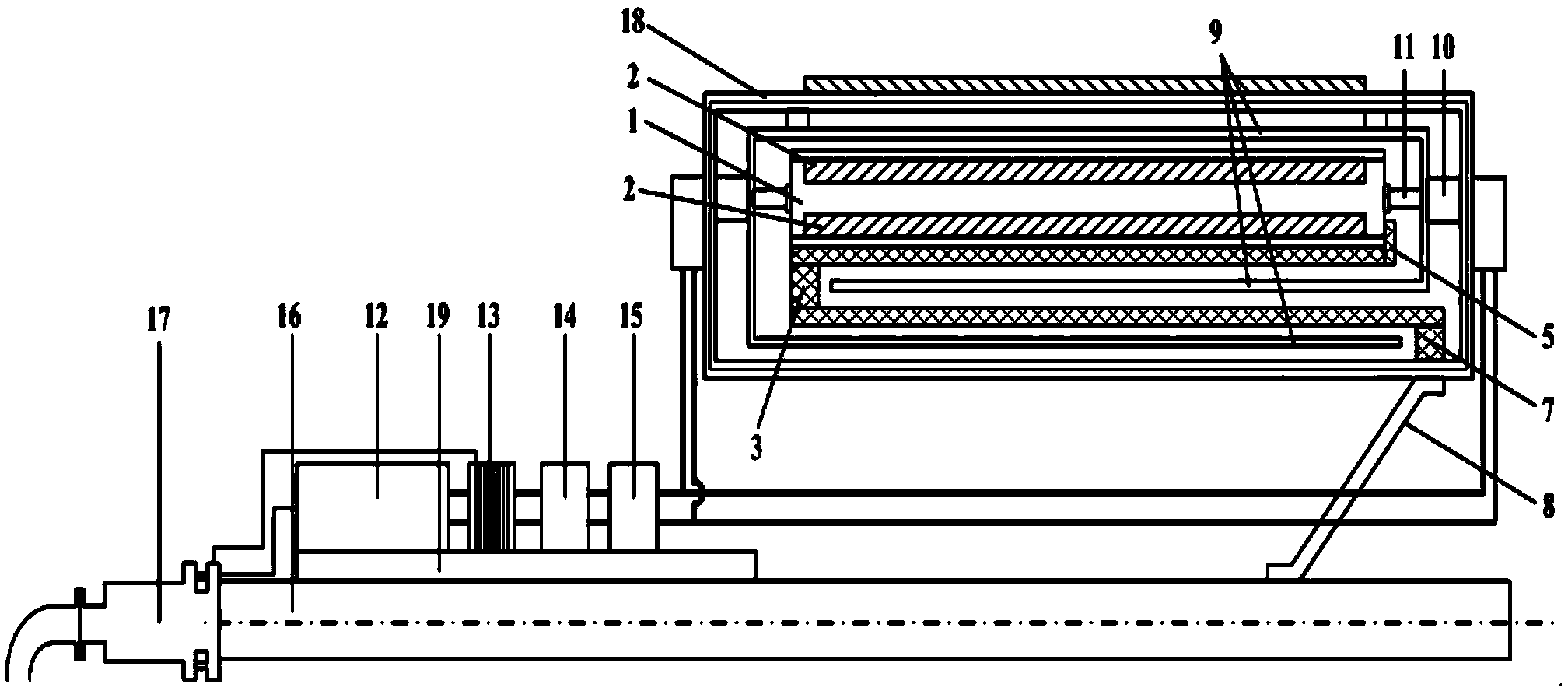

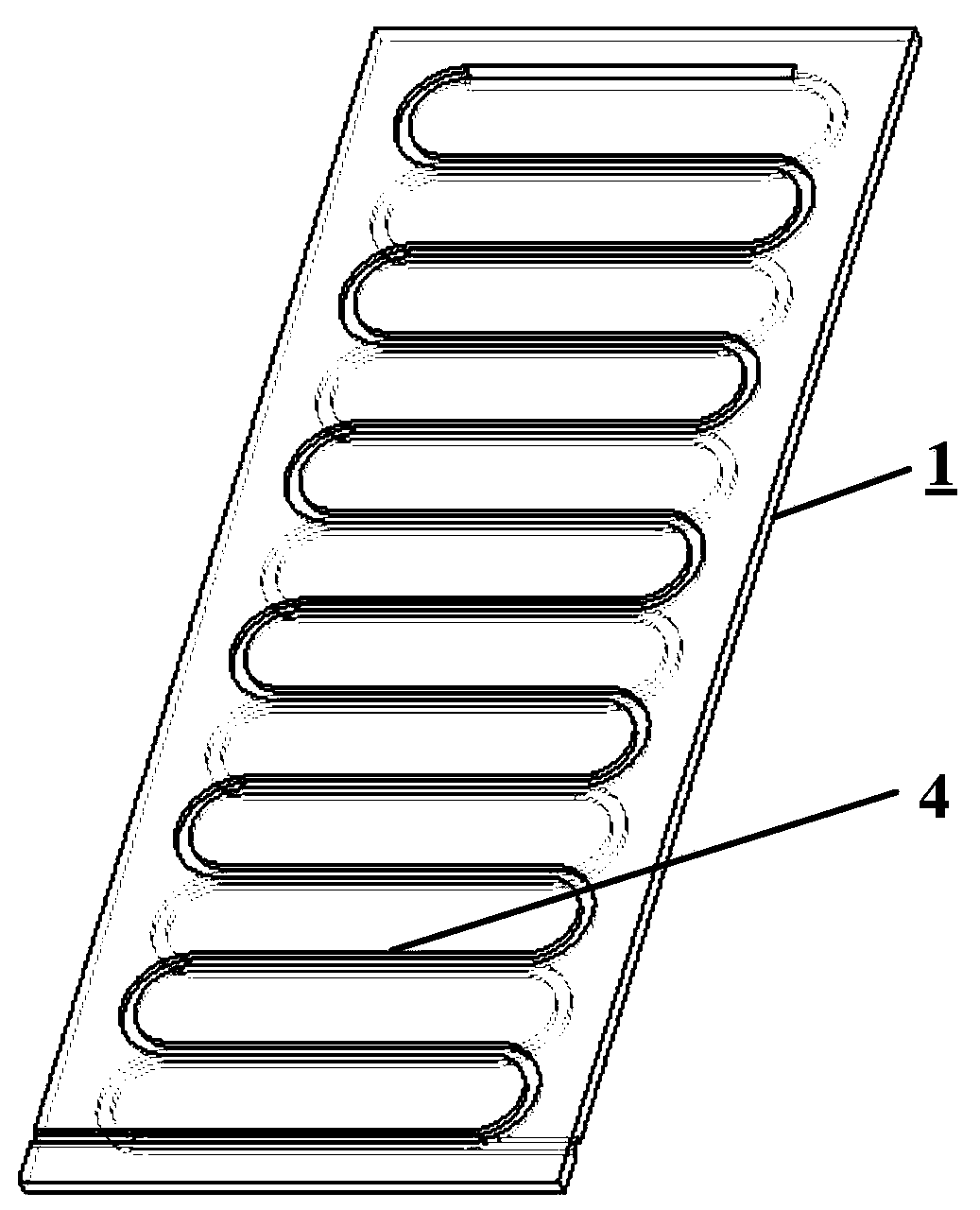

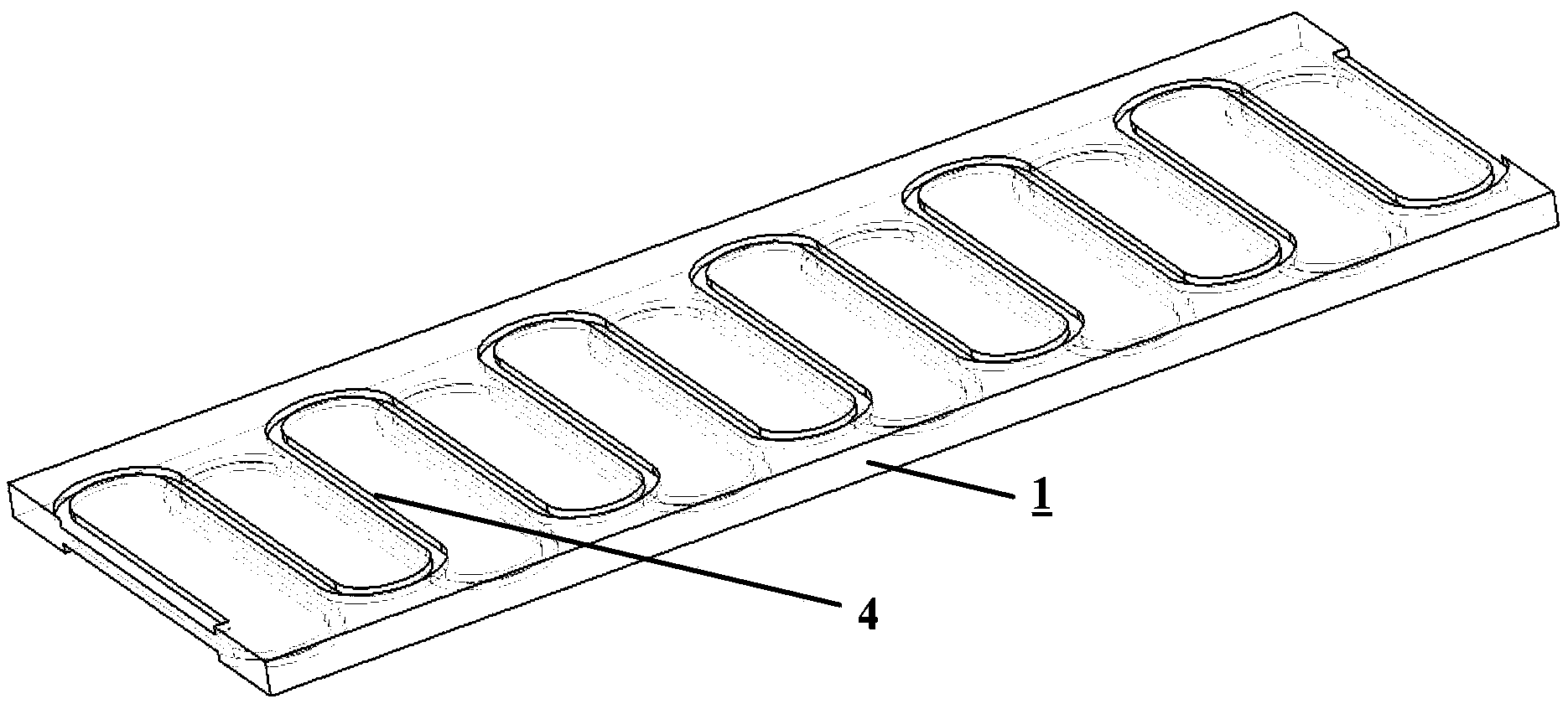

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 shown. Build an ironless megawatt-class superconducting motor system, including a conventional stator, a superconducting rotor with an ironless structure, and a low-temperature refrigeration device; the axial length of the rotor is 1.5m, and the rotor diameter is 1.2m. Specific structure: The stator is a copper armature winding with a double-layer structure. The rotor includes a bobbin 1 , a superconducting excitation coil 2 wound on the bobbin 1 with YBCO high temperature superconducting tape, and a torque tube 3 connected to the bobbin 1 . Both the upper and lower surfaces of a bobbin 1 are provided with grooves in a convoluted U-shaped structure. The groove structures on the upper and lower surfaces are 180° out of phase and connected to each other; the YBCO superconducting strip starts to wind from the beginning of the upper surface groove system, wound to the end of the ...

Embodiment 2

[0041] The parts that are the same as those in Embodiment 1 will not be described again, except that the axial length of the rotor is 2.0 m, and the diameter of the rotor is 1.5 m. Using low temperature superconducting material MgB 2 The wire is wound on the bobbin 1 to form a superconducting excitation coil 2 . The grooves on the upper and lower surfaces of the bobbin 1 are structurally independent of each other, MgB 2 The wires are respectively wound on the upper and lower surfaces of the bobbin 1 , and finally the superconducting excitation coil 2 wound on the upper surface of the bobbin 1 and the superconducting exciting coil 2 wound on the lower surface of the bobbin 1 are independent of each other.

Embodiment 3

[0043] The same places as in Example 1 will not be repeated, and the difference is that: the YBCO high-temperature superconducting tape 22, the BSCCO high-temperature superconducting tape 21 and the MgB 2 The low-temperature superconducting wire 20 is connected in parallel with three kinds of superconducting materials, wound on the bobbin 1 to form a superconducting excitation coil 2, and the three kinds of superconducting materials are arranged in sequence along the direction close to the bobbin 1 as MgB 2 Low-temperature superconducting wire 20, BSCCO high-temperature superconducting tape 21 and YBCO high-temperature superconducting tape 22 (the specific structure is as follows Figure 8 shown), that is, the farthest from the bobbin 1 is MgB 2 The low-temperature superconducting wire 20, and the YBCO high-temperature superconducting strip 22 closest to the bobbin 1; the superconducting excitation coil 2 wound on the upper and lower surfaces of the bobbin 1 is formed by contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com