Catalyst for exhaust gas purification

A technology of exhaust gas purification and catalyst, applied in the direction of physical/chemical process catalyst, catalyst activation/preparation, heterogeneous catalyst chemical elements, etc., can solve the problem of oxygen absorption efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

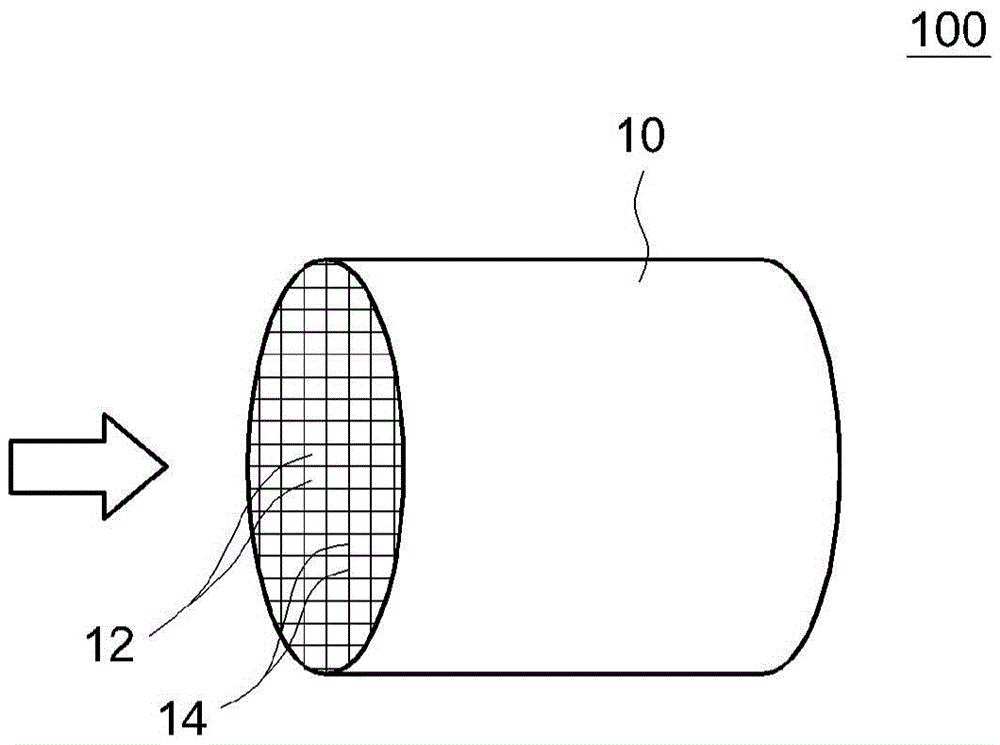

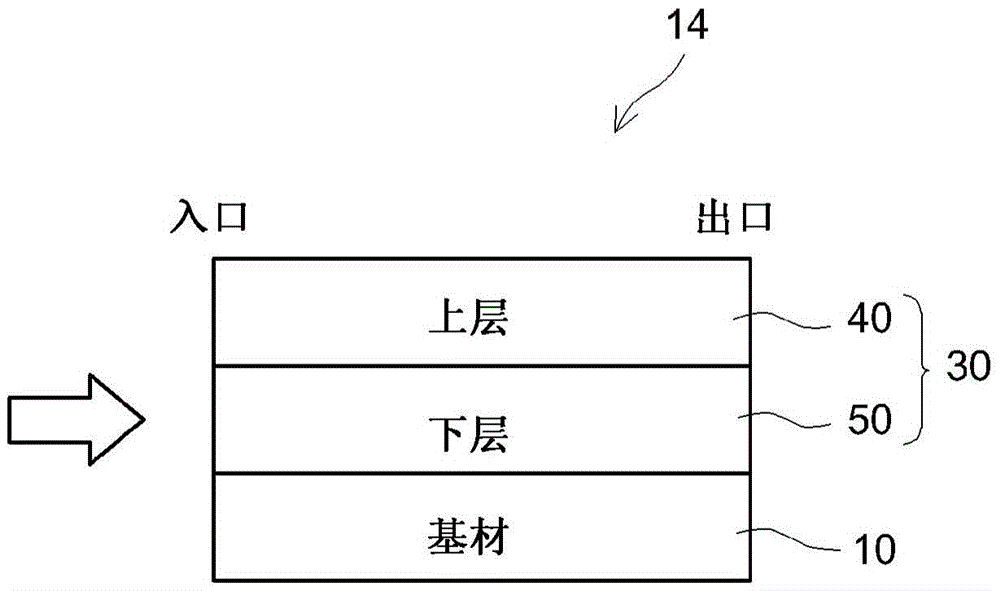

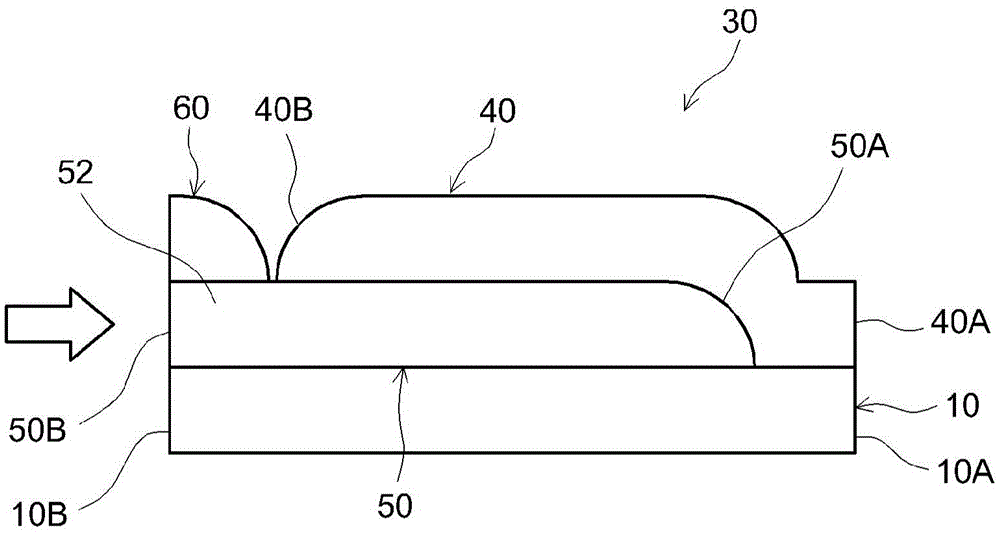

[0072] A catalyst for exhaust gas purification in which Rh was arranged in the upper layer and Pd was arranged only in the lower layer was manufactured in Example 1.

[0073] (1) Formation of the lower layer

[0074] By adding 75g / L alumina (Al 2 o 3 ) powder was suspended in the nitric acid type Pd reagent solution containing 0.82g / L Pd to prepare a dispersion. Mix the following into this dispersion to obtain a slurry: CeO 2 -ZrO 2 Composite oxide OSC material powder (CeO 2 : 30% by weight, ZrO 2 : 60% by weight, Y 2 o 3 : 5% by weight, La 2 o 3 : 5% by weight), 5% by weight barium acetate, 5% by weight Al 2 o 3 binder, and distilled water. The slurry was dried at 120° C. for 30 minutes and calcined at 500° C. for 2 hours to obtain a catalyst material for the lower layer.

[0075] Then, this lower layer catalyst material was dispersed in an acidic aqueous solution to prepare a lower layer forming slurry (A). Using this underlayer-forming slurry (A), washcoating ...

example 2~5

[0082] Catalysts for purifying exhaust gas in which Rh was arranged in the upper layer and Pd was arranged in both the upper layer and the lower layer were prepared in Examples 2 to 5. Specifically, a certain amount of catalyst material for a lower layer is subtracted from the above-mentioned slurry (A) for forming a lower layer and the same amount of catalyst material for a lower layer is mixed into the slurry (B) for forming an upper layer. A front stage upper layer forming slurry (C) was prepared as in Example 1. Proceeding as in Example 1, these three slurries (A), (B) and (C) were washed-coated on a substrate and dried and calcined to produce a catalyst for exhaust gas purification. This production was performed so as to provide Pd amounts of 0.04 g, 0.08 g, 0.16 g, and 0.24 g in the entire upper layer in the order of Examples 2 to 5, respectively. The amount of Pd in the entire catalyst was kept constant at 0.65 g.

example 6

[0084] A catalyst for purification of exhaust gas in which Rh was arranged in the upper layer and Pd was arranged in both the upper layer and the lower layer was produced in Example 6. However, in this example, Pd in the upper layer was disposed therein without being supported on the carrier. Specifically, a certain amount of Pd (without support) was subtracted from the above-mentioned lower layer-forming slurry (A) and the same amount of Pd (without support) was mixed into the upper layer-forming slurry (B). A front stage upper layer forming slurry (C) was prepared as in Example 1. Proceeding as in Example 1, these three slurries (A), (B) and (C) were washed on the substrate and dried and calcined to prepare a catalyst for exhaust gas purification. This production was performed so as to provide a Pd amount of 0.16 g in the entire upper layer.

[0085] For the catalysts for exhaust gas purification according to Examples 1 to 6, given in Table 1 below: the amount of Pd in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com