Catalyst for preparing propylene through propane dehydrogenation, and preparation method and application thereof

A propane dehydrogenation and catalyst technology, applied in the direction of catalyst activation/preparation, catalyst, carbon compound catalyst, etc., can solve the problems of Pt-Sn catalyst deactivation, strong acidity of carrier, alloying, etc., and achieve the suppression of Pt sintering and Sn precipitation , Reduce the acidity of the carrier, improve the catalytic performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

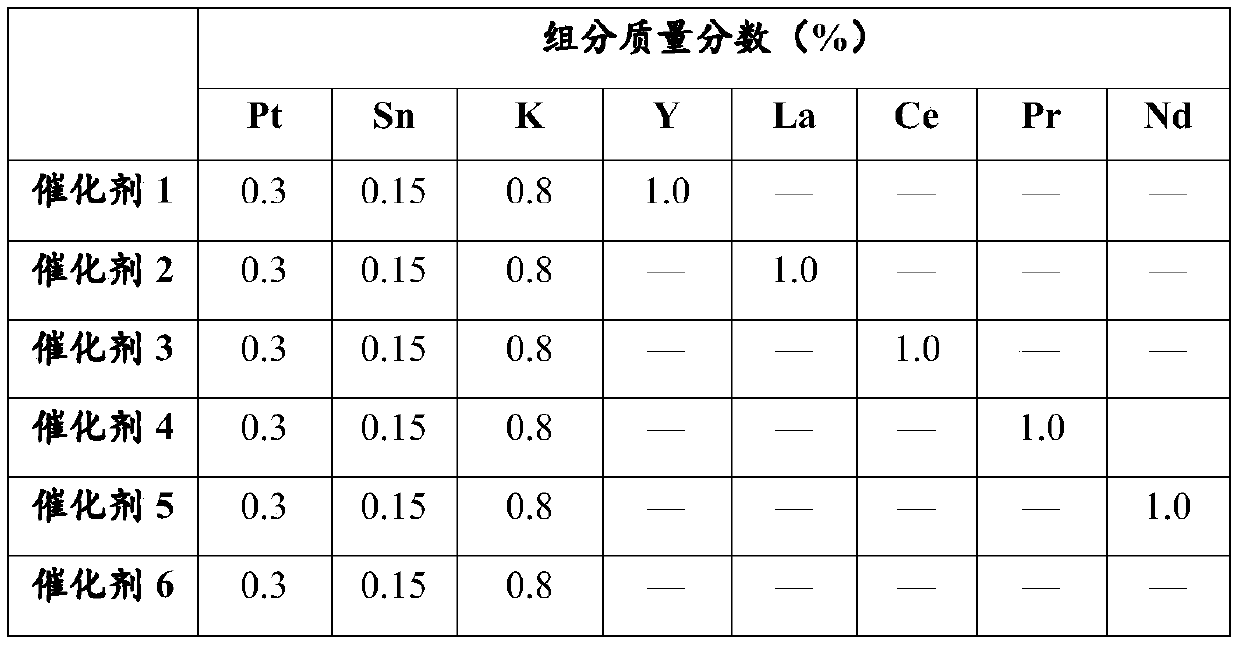

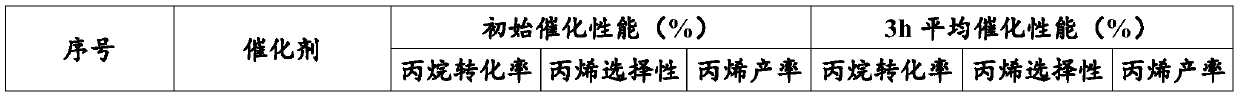

[0040] This embodiment prepares catalyst 1, Pt-Sn-K-Y / Al 2 o 3 , and its catalytic performance of propane dehydrogenation to propylene was tested.

[0041] Preparation: 1) configure H with a mass concentration of 0.02g / g 2 PtCl 6 ·6H 2 O solution, SnCl with a mass concentration of 0.04g / g 2 2H 2 O solution. Take H respectively 2 PtCl 6 ·6H 2 O solution and SnCl 2 2H 2 O solution 4.075g and 0.729g, then add concentrated hydrochloric acid and deionized water to make the volume of Pt-Sn impregnation solution equal to 10g Al 2 o 3 The total water absorption of the carrier, and the mass of concentrated hydrochloric acid is 8.3% of the mass of the impregnation solution. After stirring evenly, impregnate 10g Al 2 o 3 ball carrier. After soaking for 4 hours, vacuum-dry at 100°C for 8 hours, and bake at 600°C for 4 hours;

[0042] 2) Configure KNO with a mass concentration of 0.07g / g 3 Solution, YCl with a mass concentration of 0.312g / g 3 solution. Take KNO respectivel...

Embodiment 2

[0045] This embodiment prepares catalyst 2, Pt-Sn-K-La / Al 2 o 3 , and its catalytic performance of propane dehydrogenation to propylene was tested.

[0046] Preparation: 1) configure H with a mass concentration of 0.02g / g 2 PtCl 6 ·6H 2 O solution, SnCl with a mass concentration of 0.04g / g 2 2H 2 O solution. Take H respectively 2 PtCl 6 ·6H 2 O solution and SnCl 2 2H 2 O solution 4.075g and 0.729g, then add concentrated hydrochloric acid and deionized water to make the volume of Pt-Sn impregnation solution equal to 10g Al 2 o 3 The total water absorption of the carrier, and the mass of concentrated hydrochloric acid is 8.3% of the mass of the impregnation solution. After stirring evenly, impregnate 10g Al 2 o 3 ball carrier. After soaking for 4 hours, vacuum-dry at 100°C for 8 hours, and bake at 600°C for 4 hours;

[0047] 2) Configure KNO with a mass concentration of 0.07g / g 3 Solution, LaCl with a mass concentration of 0.271g / g 3 solution. Take KNO respect...

Embodiment 3

[0050] This embodiment prepares catalyst 3, Pt-Sn-K-Ce / Al 2 o 3 , and its catalytic performance of propane dehydrogenation to propylene was tested.

[0051] Preparation: 1) configure H with a mass concentration of 0.02g / g 2 PtCl 6 ·6H 2 O solution, SnCl with a mass concentration of 0.04g / g 2 2H 2 O solution. Take H respectively 2 PtCl 6 ·6H 2 O solution and SnCl 2 2H 2 O solution 4.075g and 0.729g, then add concentrated hydrochloric acid and deionized water to make the volume of Pt-Sn impregnation solution equal to 10g Al 2 o 3 The total water absorption of the carrier, and the mass of concentrated hydrochloric acid is 8.3% of the mass of the impregnation solution. After stirring evenly, impregnate 10g Al 2 o 3 ball carrier. After soaking for 4 hours, vacuum-dry at 100°C for 8 hours, and bake at 600°C for 4 hours;

[0052] 2) Configure KNO with a mass concentration of 0.07g / g 3 Solution, Ce(NO with a mass concentration of 0.2g / g 3 ) 3 ·6H 2 O solution. Tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com