Secondary battery

A secondary battery and conductive material technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of battery cycle characteristics deterioration, current collector deterioration, lithium consumption, etc., achieve good electronic conductivity and prevent deterioration , Improve the effect of cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0122] Examples and comparative examples are shown below to further describe the present invention in detail. In addition, the scope of the present invention is not limited by this embodiment. The secondary battery and the power supply system of the present invention can be appropriately modified and implemented without changing the gist of the present invention.

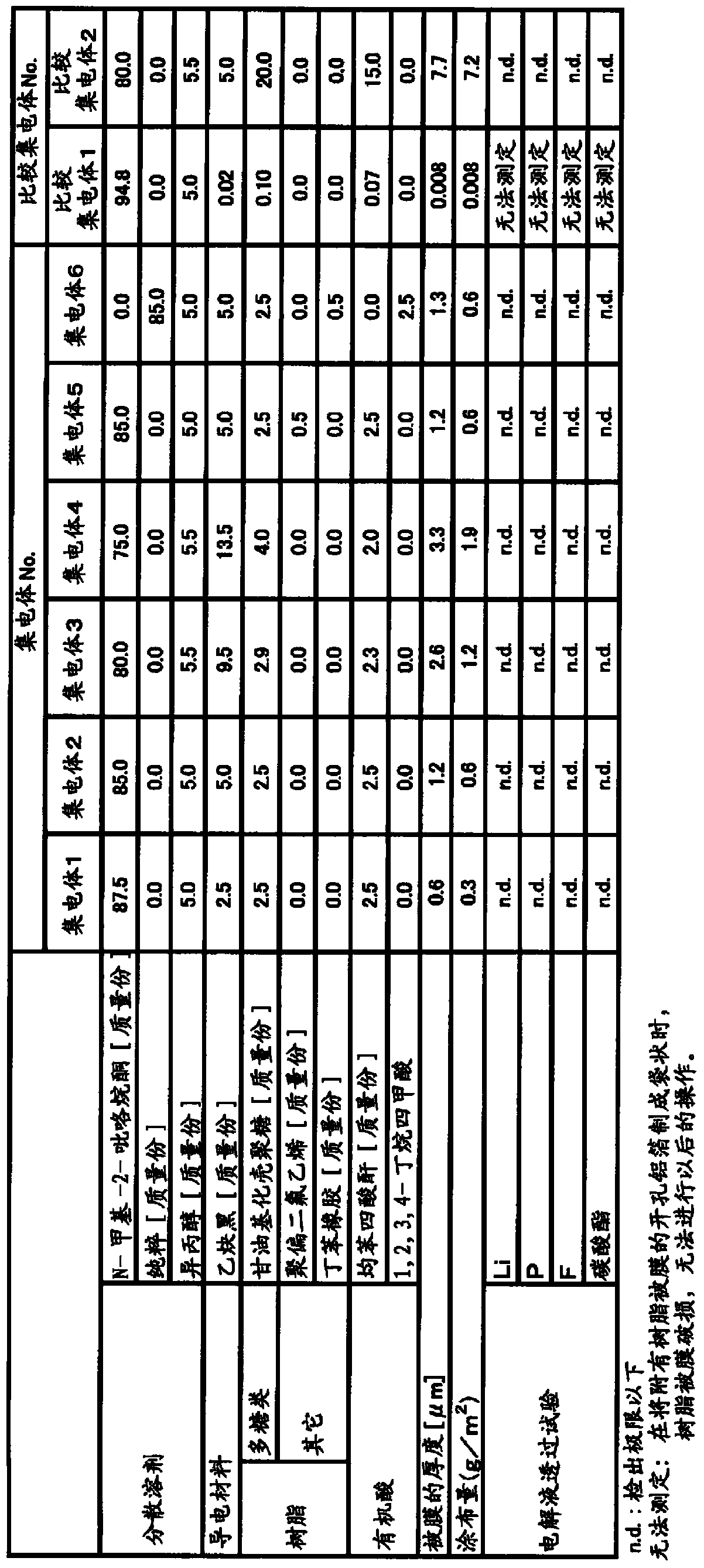

manufacture example

[0124] Disperse the raw materials shown in Table 1 for 10 minutes at a speed of 300 rpm using a Dissolver-type mixer, and further process them with a homogenizer (manufactured by Iada Trading Co., Ltd., product name PRO200) at 20,000 rpm for 30 seconds to fully disperse , to produce a coating solution.

[0125] Next, an aluminum foil made of an A1085 material and having a thickness of 30 μm (thickness of the oxide film: 3 nm) was prepared after alkali cleaning. Depending on the thickness of the film to be formed, the coating liquid was applied to one side of the aluminum foil by a bar coating method using a Meyer rod #0, #1, or #2. Then, it heat-dried at 180 degreeC in air|atmosphere for 3 minutes. The coating was similarly applied to the other surface in the same manner, followed by heating and drying to obtain current collectors 1 to 6 having a resin film.

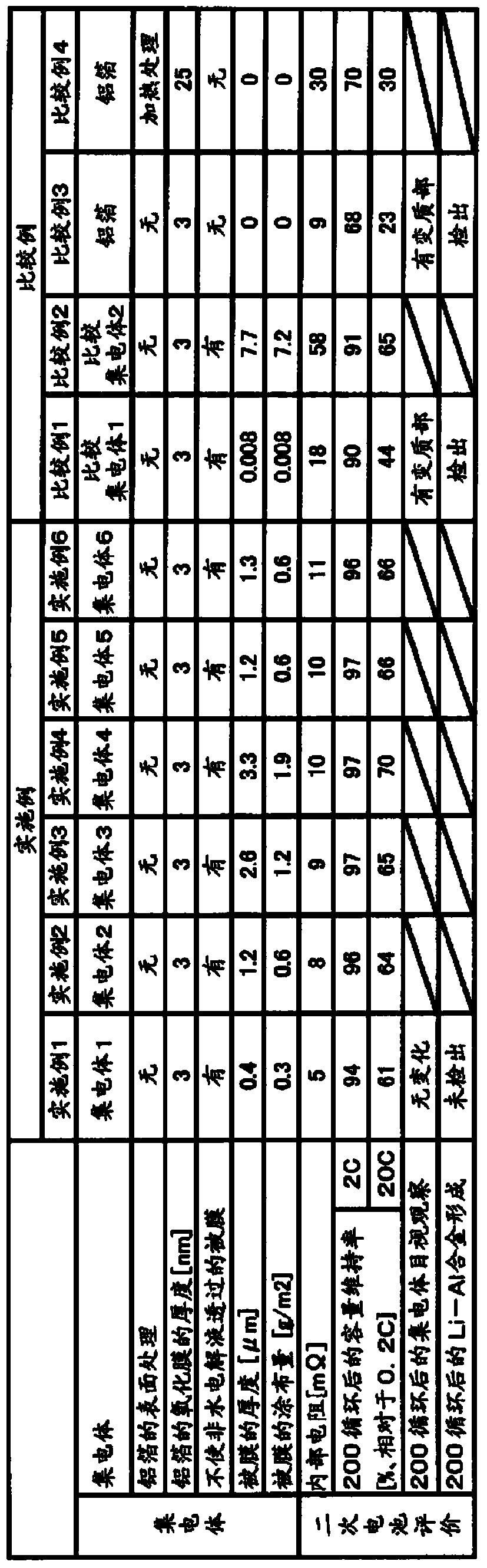

Embodiment 1~6

[0143] (manufacturing of secondary batteries)

[0144] The aforementioned current collectors 1 to 6 were each cut out to a size of 10 cm×10 cm. 94 parts by mass of artificial graphite (manufactured by Showa Denko Co., Ltd., trade name SCMG-AR) as a negative electrode active material, acetylene black (manufactured by Denki Kagaku Kogyo Co., Ltd., trade name denka black (powder)) as a conductive additive ) 1 mass part, 5 mass parts of polyvinylidene fluoride (manufactured by Co., Ltd. Kureha, trade name KF Polymer #9130) as a binder, 94 N-methyl-2-pyrrolidone (industrial grade) as a dispersion solvent Parts by mass were mixed to obtain a slurry, and the slurry was applied to both surfaces of current collectors 1 to 6, dried and pressed to form a negative electrode active material layer with a thickness of 55 μm on one side, thereby producing a negative electrode.

[0145] On the other hand, 95 parts by mass of lithium cobaltate (manufactured by Nippon Chemical Industry Co., Ltd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com