X-ray recording system for differential phase contrast imaging of an examination object by way of phase stepping

A phase-contrast imaging and shooting system technology, which is applied in the fields of radiological diagnostic instruments, medical science, computer tomography scanners, etc., can solve the problems of imaging failure, inability to use high-precision optical bench, wrong imaging, etc., to achieve Guaranteed geometric accuracy, real-time measurement and correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

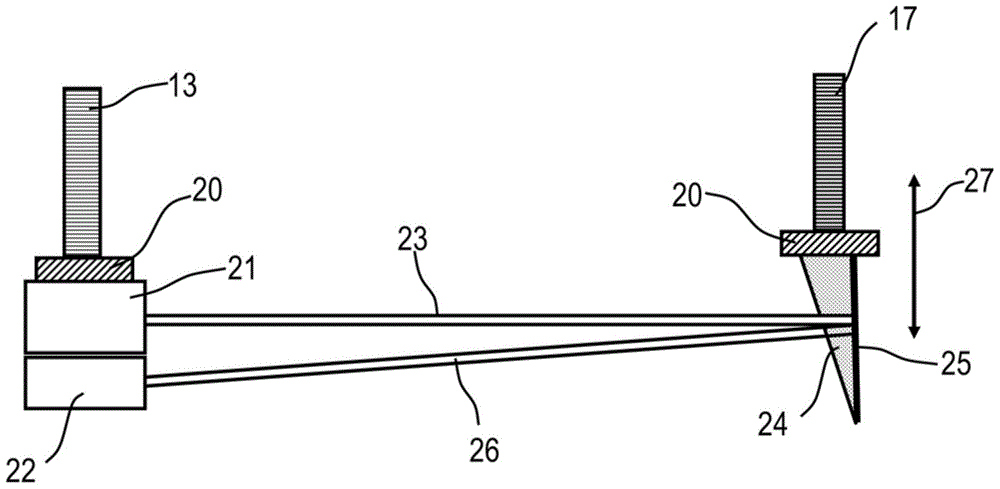

[0057] image 3 depicts for example two gratings G 0 and G 1 The principle of the detection of the height adjustment of the components. The absorption grating 13 and the phase grating 17 are held by the connecting portion 20 . The absorption grating 13 and the laser 21 are correspondingly arranged for a photosensor such as a photodiode 22 . The laser 21 emits a laser beam 23 which reaches a translucent wedge 24 assigned to the phase grating 17 and passes through the wedge 24 attenuated. On the rear side of the translucent wedge 24 is mounted a rear side mirror 25 which projects the reflected laser beam 26 further weakened by the translucent wedge 24 onto the photodiode 22 . Depending on the relative movement 27 , for example due to shocks, the reflected laser beam 26 is attenuated relative to the emitted laser beam 23 so that the output signal of the photodiode 22 describes the degree to which the position of the phase grating 17 is shifted.

[0058] exist Figure 4 For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com