Blue oxygen (o3) water production and sterilization device

A sterilizing device, blue oxygen technology, applied in the direction of dissolution, mixer, mixing method, etc., can solve the problems of insufficient mixing and poor sterilizing effect, and achieve the effect of more sterilizing effect, simple structure, and sufficient mutual dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

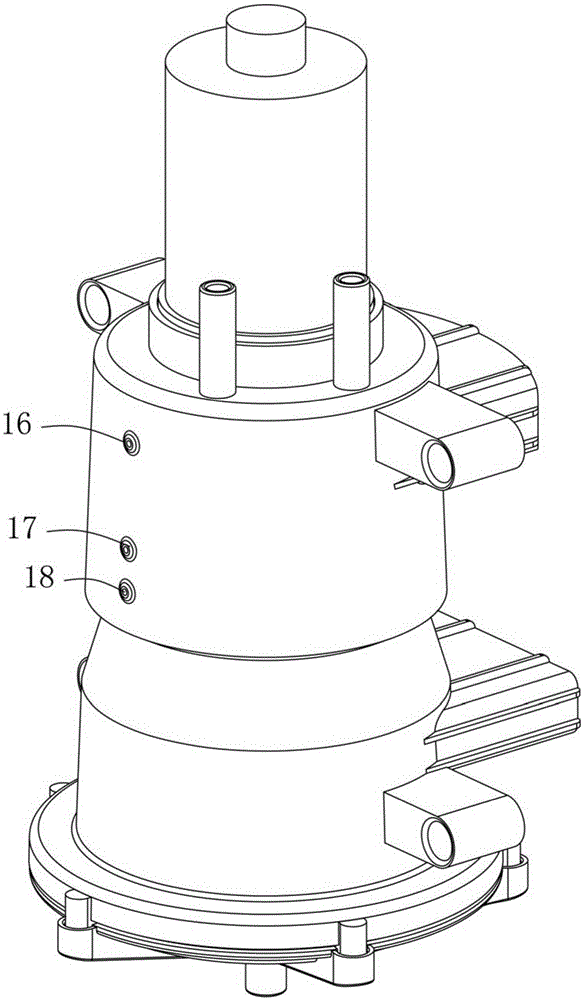

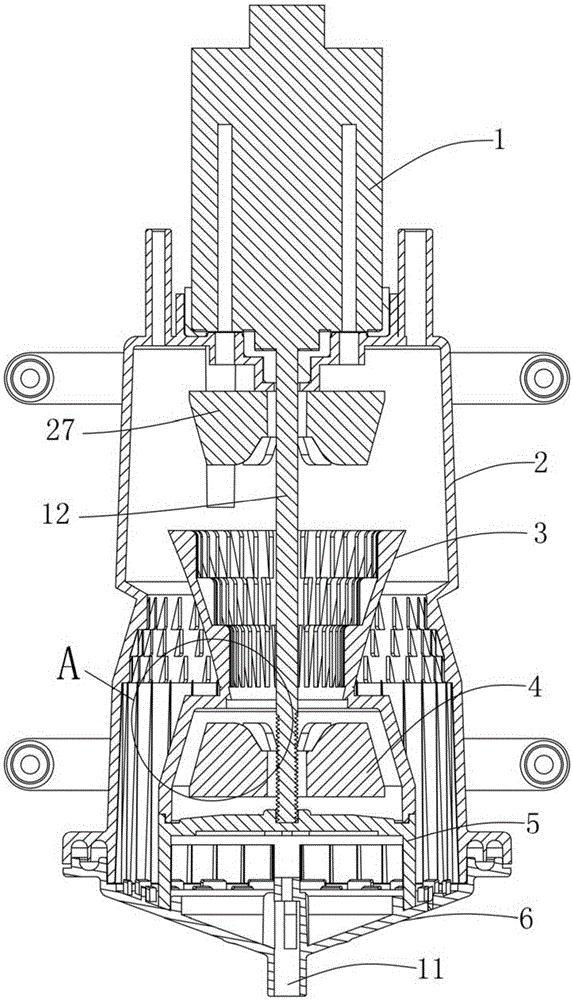

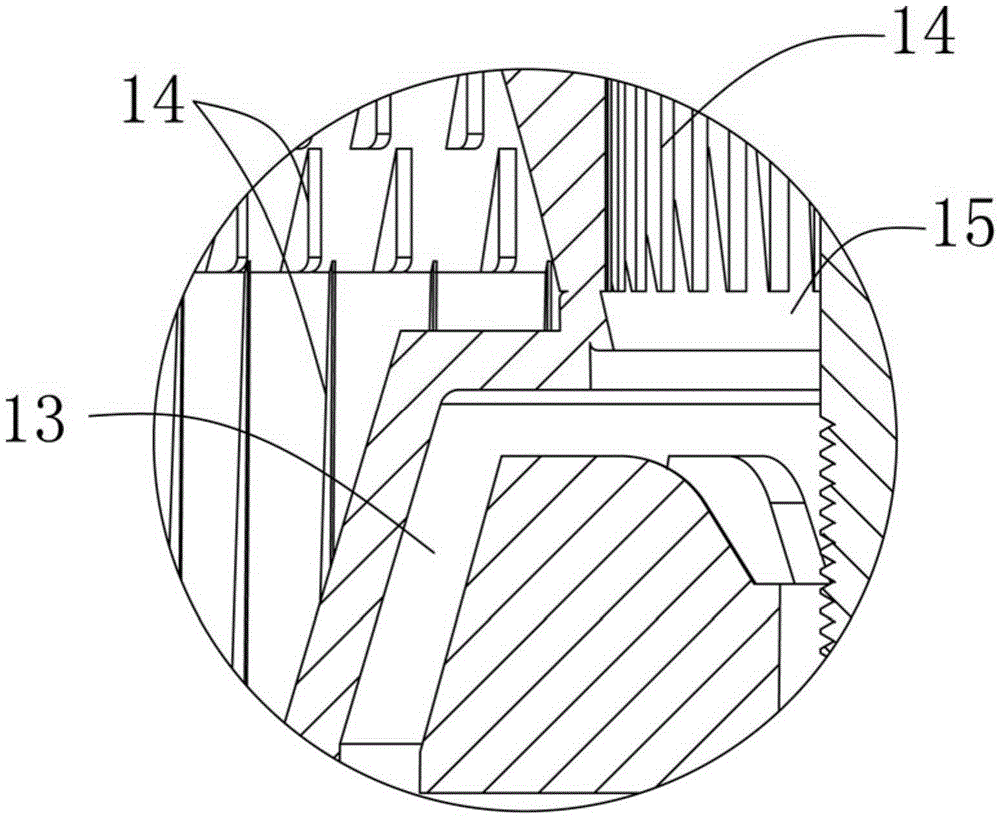

[0025] Such as Figure 1 to Figure 4 Shown, a kind of blue oxygen (O of the present invention 3 ) Water manufacturing and sterilization device, including a motor 1, a cup body 2, a suction bucket 3, a first water suction fan blade 4, a water outlet frame 5 and a cup bottom cover 6; the upper end of the cup body 2 is respectively provided with a blue oxygen inlet pipe 7, Water pipe 8, tail gas recovery pipe 9 and blue oxygen detector 10; said suction funnel 3 includes a first cavity 13 and a second cavity 15, and said first cavity 13 and said second cavity 15 communicate with each other; The motor 1 is installed above the cup body 2; the suction bucket 3, the first water suction vane 4 and the water outlet rack 5 are arranged in the inner cavity of the cup body 2; the cup bottom cover 6 is sealed and installed At the bottom of the cup body 2, a water outlet 11 is arranged axially at the lower end of the cup bottom cover 6; the suction bucket 3 and the water outlet frame 5 are ...

Embodiment 2

[0034] Such as Figure 8 As shown, the blue oxygen (O 3 ) Water manufacturing sterilizing device is used for industrial sterilization, blue oxygen (O 3 ) The water manufacturing sterilizing device is connected with the industrial sterilizing machine.

[0035] One with blue oxygen (O 3 ) An industrial sterilizer used in conjunction with a water manufacturing sterilizing device, including an assembly line 21, a product to be sterilized 22, a nozzle 23, a sterilization chamber 24 and a drying evaporation zone 25, the water outlet 11 is connected to the nozzle 23, and the nozzle 23 corresponds to the sterilization chamber 24 , the product to be sterilized 22 is located at the right end of the assembly line 21 , and the drying and evaporation area 25 is set at the left end of the sterilization chamber 24 .

[0036] During work, the water outlet 11 outputs blue oxygen water, sprays blue oxygen water from the nozzle 23, and the assembly line 21 starts to work. The product 22 to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com