A extrusion granulator

A granulator and frame technology, applied in metal processing, etc., can solve the problems that dehydration and granulation cannot be separated, dehydration machines cannot be purchased, waste plastics are messy, etc., to facilitate sales and circulation, reduce transmission difficulty, and low water content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through specific examples.

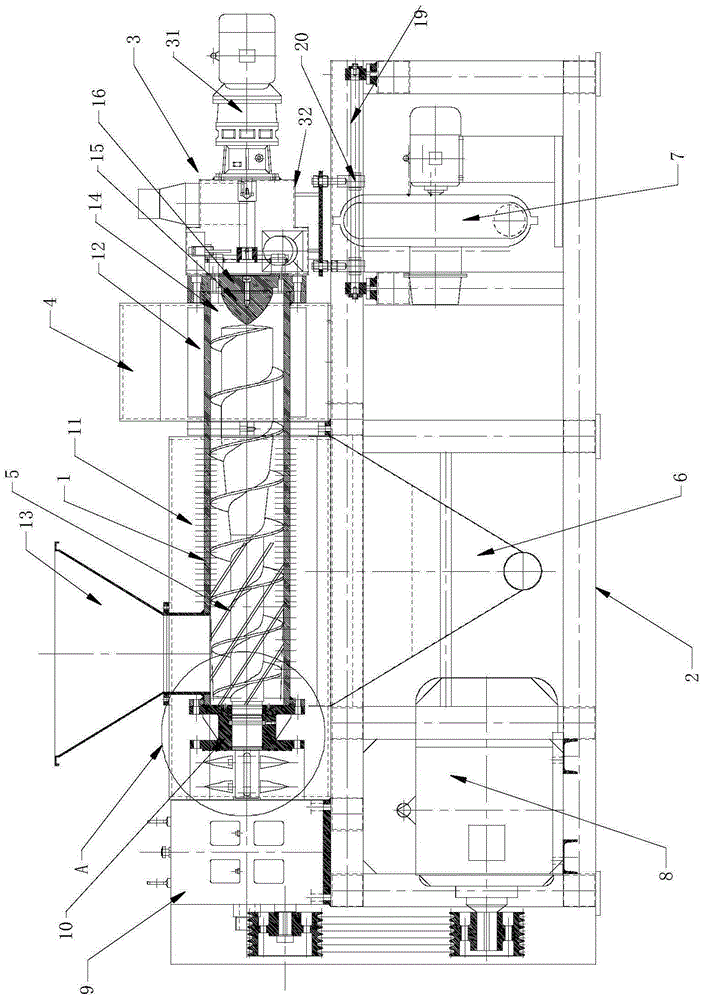

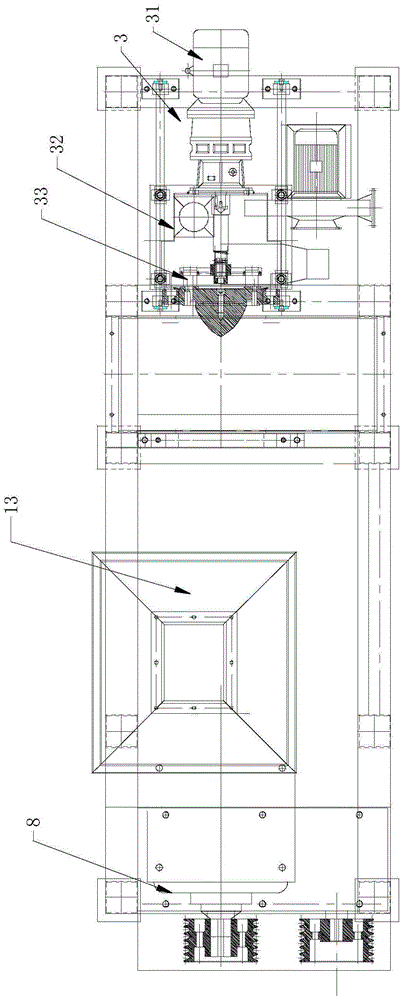

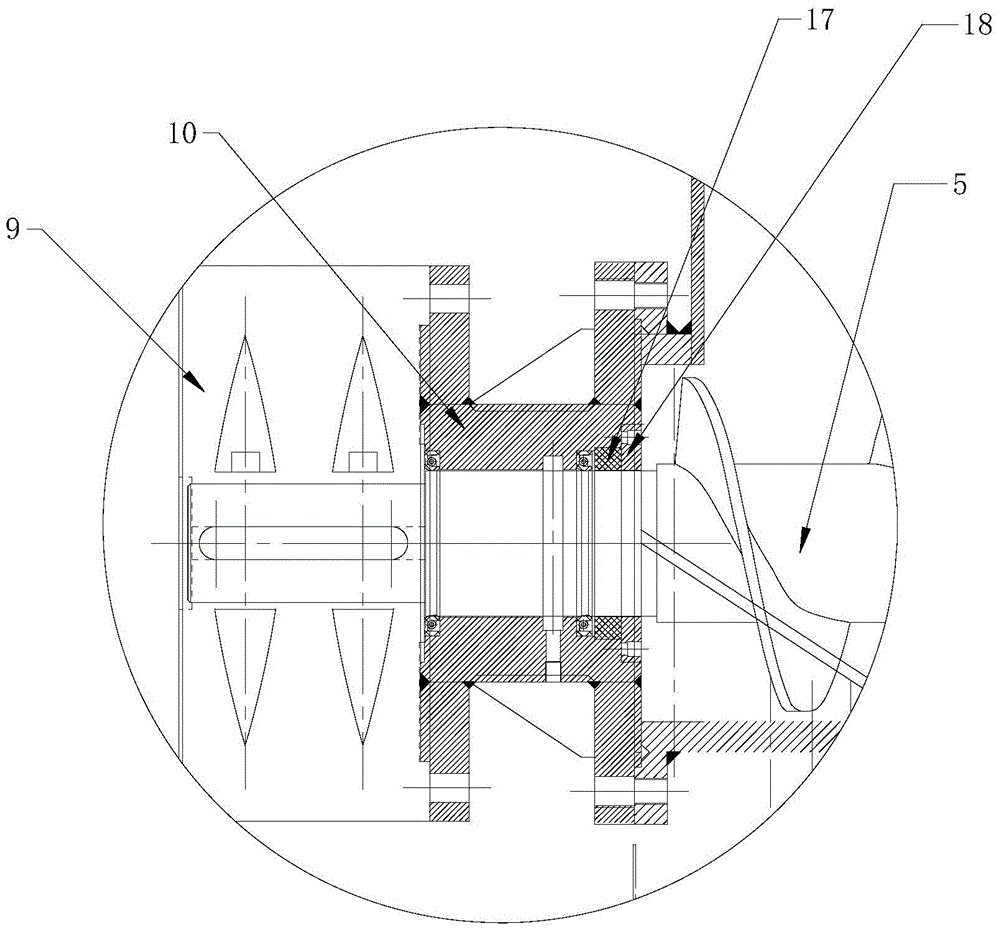

[0020] Such as figure 1 , 2 , 3, a kind of extruding pre-granulator, including frame 2, extruding cylinder 1, heating device 4 and pre-granulation device 3, described extruding cylinder 1 is installed on the frame 2, and this extruding cylinder One end of 1 is provided with a feed port 13, and the other end is provided with an extrusion port 14. A squeeze screw 5 is installed in rotation in the squeeze barrel 1. The squeeze screw is connected with a screw power unit, and the barrel body of the squeeze barrel 1 is upstream The section 11 is provided with a water filter hole, and a water collecting bucket 6 is arranged under the squeeze barrel 1 to collect the water flowing out from the water filter hole, and the water can be reused after depositing impurities. The heating device 4 is installed in the downstream section 12 of the squeeze barrel 1 to heat the material in the sque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com