Electric daylighting and smoke exhaust louver

A skylight, electric technology, applied in the direction of roof, building, building structure, etc., can solve the problems of safety hidden danger of building fire and smoke exhaust application, small effective ventilation area, opening time restriction, etc., to achieve strong ability to adapt to natural climate changes, reduce Energy consumption to adjust the cooling time and improve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

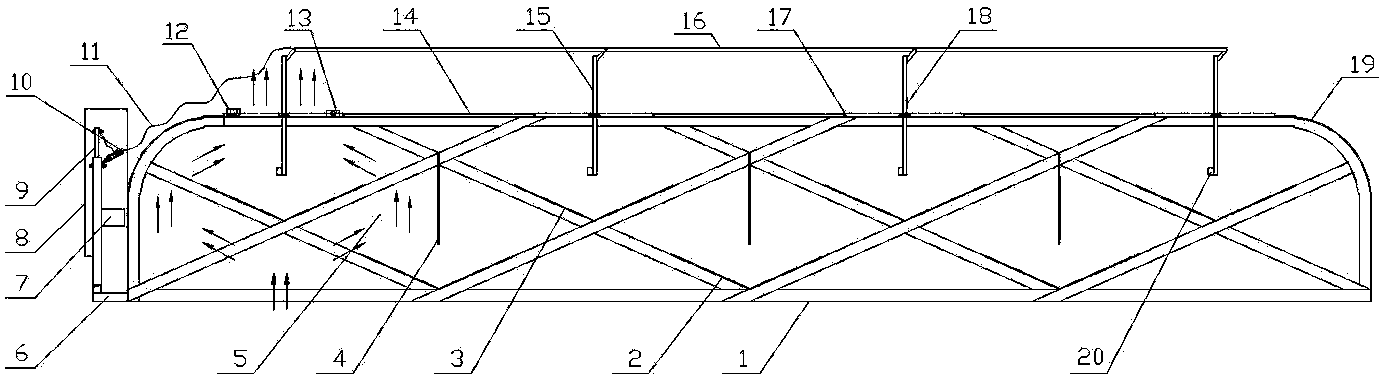

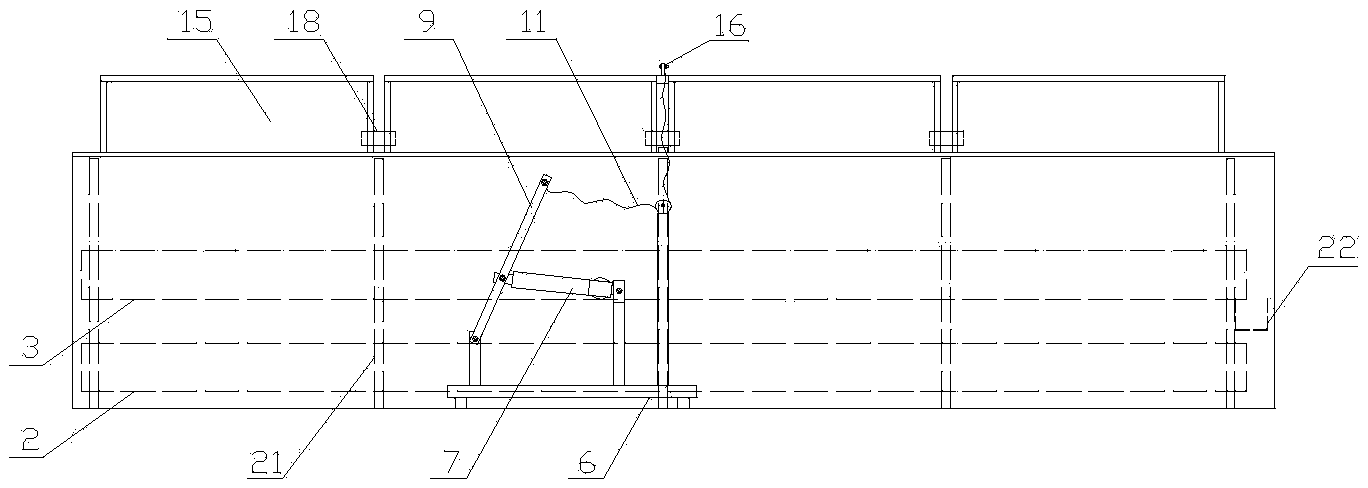

[0026] As shown in the figure, the electric daylighting and smoke-exhausting skylight includes a truss structure 1 arranged on the basis of building roof vents and connected with each other by multiple rows of truss purlins 21 arranged side by side. As a preference, this embodiment uses five rows of truss purlins 21 as an example, five rows of truss purlins 21 are connected to each other through a plurality of evenly distributed longitudinal rods 17 . Windshields 19 are fixed around the truss structure 1, and upper, middle and lower layers of rainshields are evenly arranged on the truss structure 1 respectively. The upper rain shield 14 is a flat plate, the middle rain shield 3 and the lower rain shield 2 are V-shaped, the lower rain shield 2 is located directly below the corresponding upper rain shield 14, and the middle rain shield 3 is located at the opposite side. Between the two groups of adjacent upper and lower rain shields, the middle rain shield 3 has a certain degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com