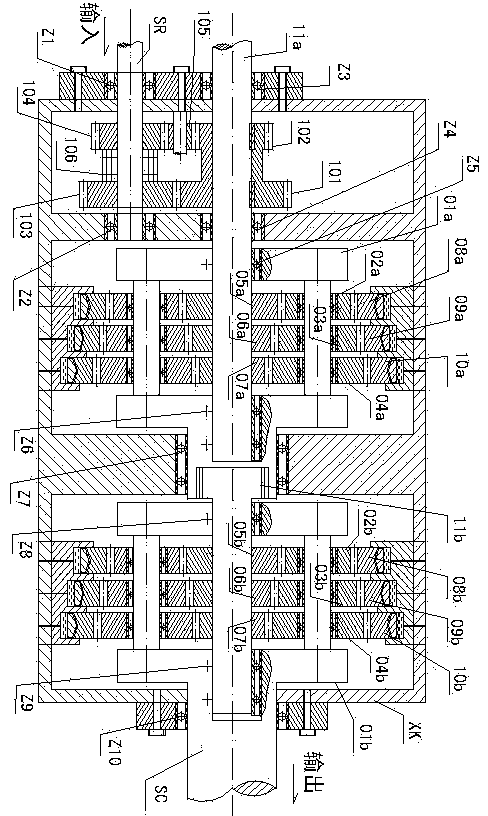

Combined type planetary gear set gearbox

A planetary gear set and planetary gear technology, which is applied in vehicle gearboxes, gear transmissions, belts/chains/gears, etc., can solve problems such as low transmission efficiency, shifting frustration, and steel belt drive stepless gearboxes are prone to heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

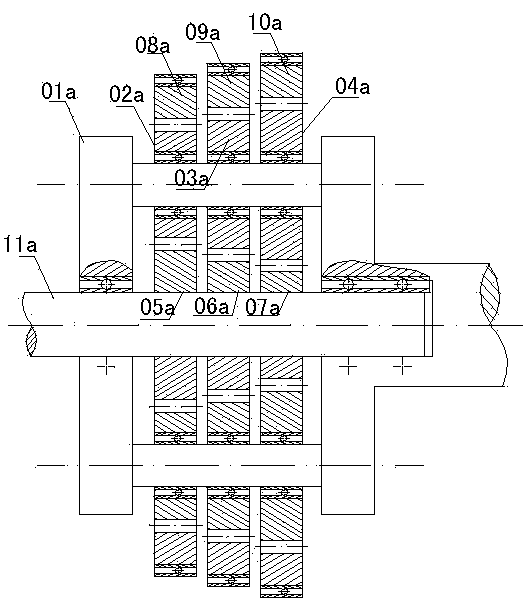

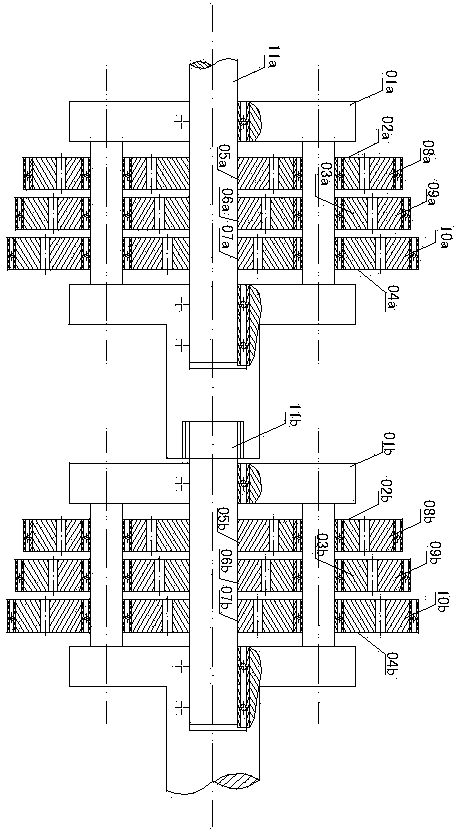

[0027] Figure 8 In this embodiment, there are six forward gears and six reverse gears, the power from the engine is input to the total input shaft (SR) of the compound planetary gear set gearbox, and the input shaft (SR) is coaxially provided with an input gear A gear (103) and an input reverse gear (104), and a gear synchronizer (106) is also arranged between the two gears for selecting forward gear, reverse gear or neutral gear. When the gear synchronizer (106) is connected to the reverse gear (104), the input shaft (SR) meshes with the reverse gear (104), the reverse gear (104) meshes with the reverse idler gear (105), and the reverse idler gear (105) The input shaft (11a) of the first compound planetary gear unit is engaged, so that the power is transmitted to the compound planetary gear unit; when the gear synchronizer (106) is connected to the input gear (103), the input shaft (SR) meshes with the input gear (103), the input gear (103) meshes with the input shaft (11a)...

specific Embodiment approach 3

[0029] Figure 9 In this embodiment, there are four forward gears and four reverse gears, the power from the engine is input to the total input shaft (SR) of the compound planetary gear set gearbox, and the input shaft (SR) is coaxially provided with an input gear A gear (103) and an input reverse gear (104), and a gear synchronizer (106) is also arranged between the two gears for selecting forward gear, reverse gear or neutral gear. When the gear synchronizer (106) is connected to the reverse gear (104), the input shaft (SR) meshes with the reverse gear (104), the reverse gear (104) meshes with the reverse idler gear (105), and the reverse idler gear (105) The input shaft (11a) of the first compound planetary gear unit is engaged, so that the power is transmitted to the compound planetary gear unit; when the gear synchronizer (106) is connected to the input gear (103), the input shaft (SR) meshes with the input gear (103), the input gear (103) meshes with the input shaft (11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com