Improved adsorption type heat pump and adsorption-desorption method of improved adsorption type heat pump

An adsorption heat pump and an improved technology, applied in the field of adsorption heat pump, can solve the problems of small refrigeration performance coefficient, low refrigeration power, low effective adsorption capacity of adsorbent, etc., and achieve the effect of light weight and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

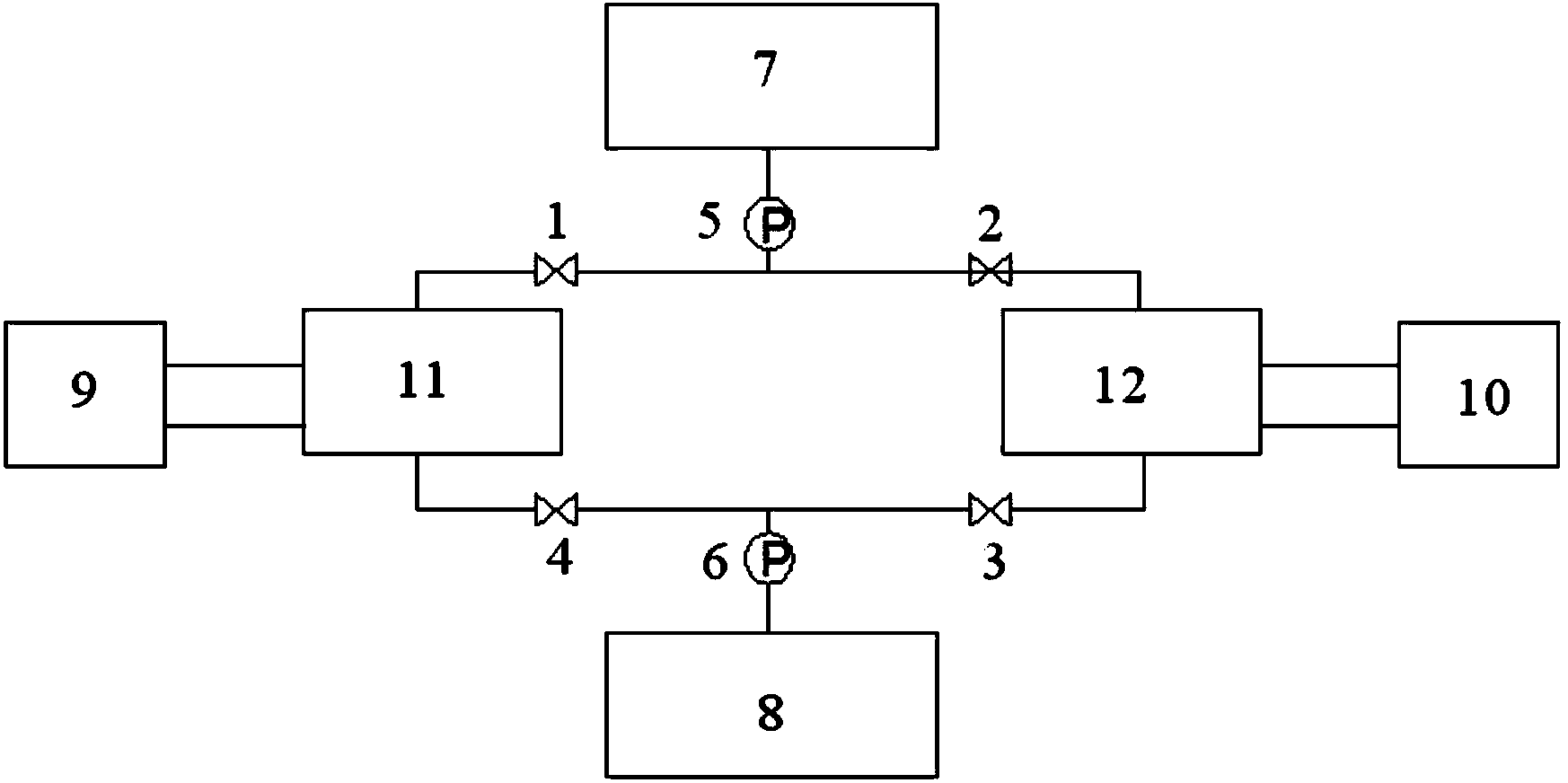

[0027] like Figure 1a As shown, an improved adsorption heat pump includes a first adsorption bed 11, a second adsorption bed 12, a condenser 7, an evaporator 8, a first vacuum booster pump 5, a second vacuum booster pump 6 and related valves wherein one end of the first adsorption bed 11 is connected to the condenser 7 through the first valve 1, the first vacuum booster pump 5 to form a loop; the other end of the first adsorption bed 11 is through the fourth valve 4, the second The vacuum booster pump 6 is connected to the evaporator 8 through a pipeline to form a loop; one end of the second adsorption bed 12 is connected to the second valve 2 through a pipeline, and is connected to the first valve 1 and the first vacuum booster pump 5. The pipeline is connected to the condenser 7 through the first vacuum booster pump 5 to form a loop; the other end of the second adsorption bed 12 is connected to the third valve 3 through the pipeline, and is connected to the fourth valve 4 an...

Embodiment 2

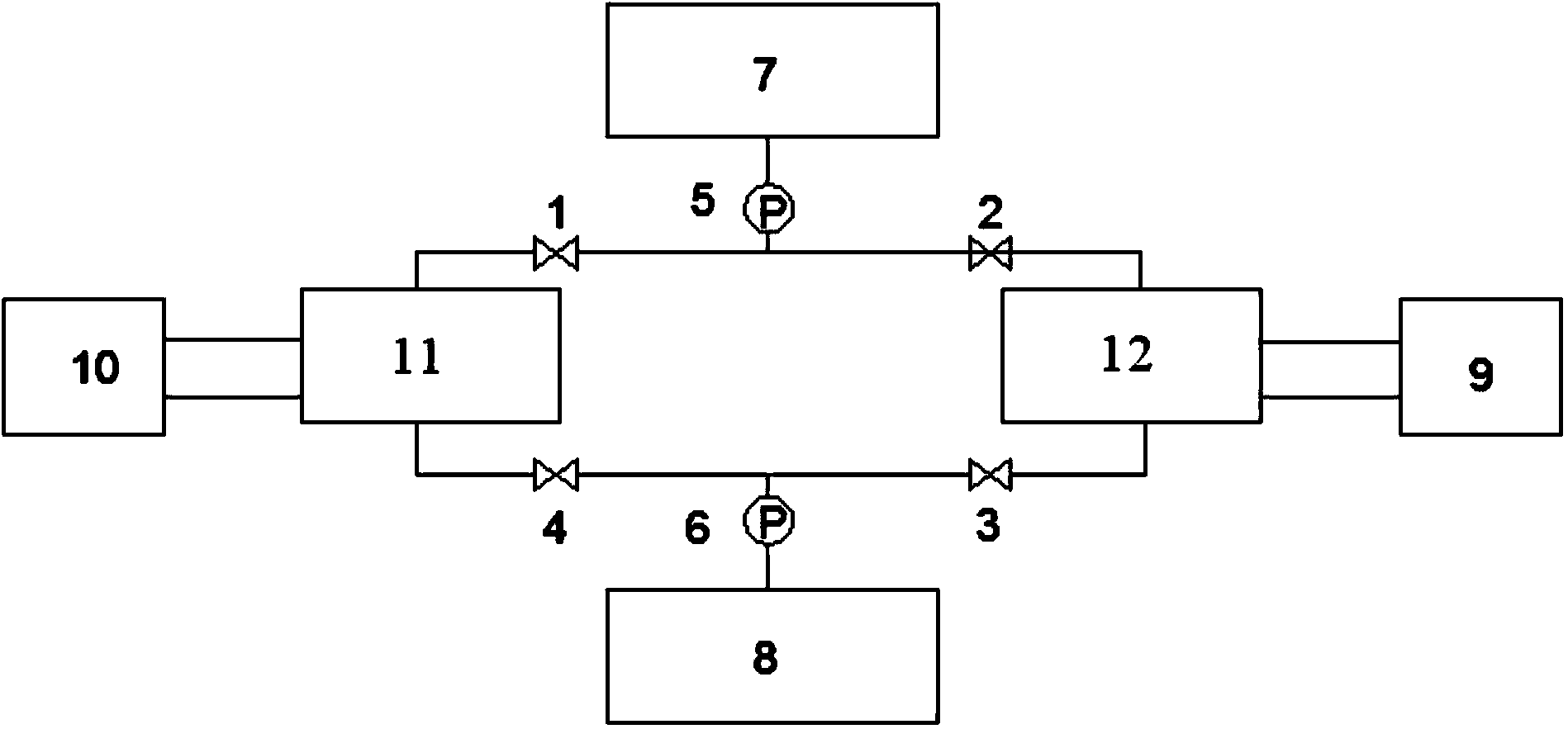

[0032] like Figure 1b As shown, an improved adsorption heat pump, the first adsorption bed 11 and the second adsorption bed 12 are respectively connected with the heat source system 10 and the cooling water system 9 to form corresponding waterways. The working process of an adsorption heat pump with a vacuum booster pump (taking refrigeration as an example): when the second adsorption bed 12 performs adsorption, the first adsorption bed 12 is connected to the cooling water system 9, and the gaseous refrigerant evaporates from the evaporator 8 After being pressurized by the second vacuum booster pump 6, it enters the adsorbent layer through the third valve 3 to complete the adsorption process; when the first adsorption bed 11 is desorbed, the first adsorption bed 11 and the heat source system 10 Then, the gaseous refrigerant is desorbed from the first adsorption bed 11, passes through the first valve 1, the first vacuum booster pump 5, and after being pressurized, enters the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com