Method for recognizing tool abrasion degree of large numerical control milling machine

A CNC milling machine and tool wear technology, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of large processing objects, difficult data collection, and less training sample data, and achieves reduction of maintenance costs and time. The effect of improving the recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

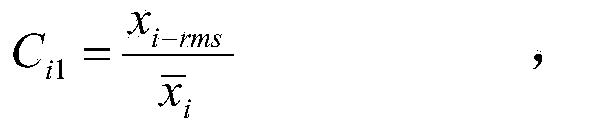

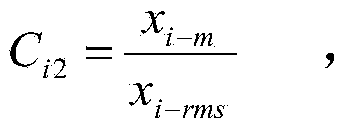

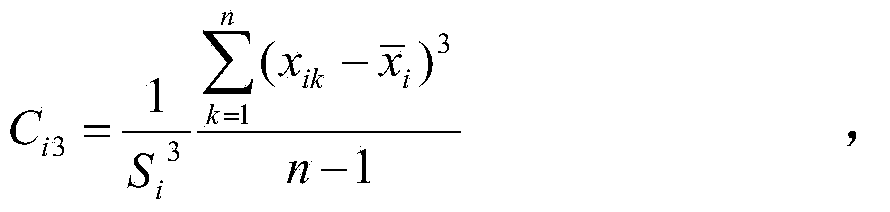

[0035] The invention provides a method for identifying the degree of tool wear of a large CNC milling machine, comprising the following steps:

[0036] (1) Collect vibration time-domain signals of large-scale CNC milling machines (usually gantry milling machines) under M kinds of tool wear states;

[0037] Among them, M is determined according to the maximum wear amount of the tool flank. In this embodiment, M=5, and the corresponding five tool wear states are divided into normal state, slight wear, moderate wear, relatively large wear, and sharp wear according to the maximum flank wear, as shown in Table 1 shown.

[0038] Table 1 Correspondence between maximum flank wear and tool wear state

[0039]

[0040] From the vibration time-domain signal of each kind of wear state, the continuous sampling number is intercepted as t (the value of t is a multiple of the sampling frequency, and t=4096 is taken in the present embodiment) non-overlapping S (depending on the amount of da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com