A Plasma Processing Device with Reduced Gate Effect

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems of uneven electric field distribution, affecting the uniformity of substrate processing, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

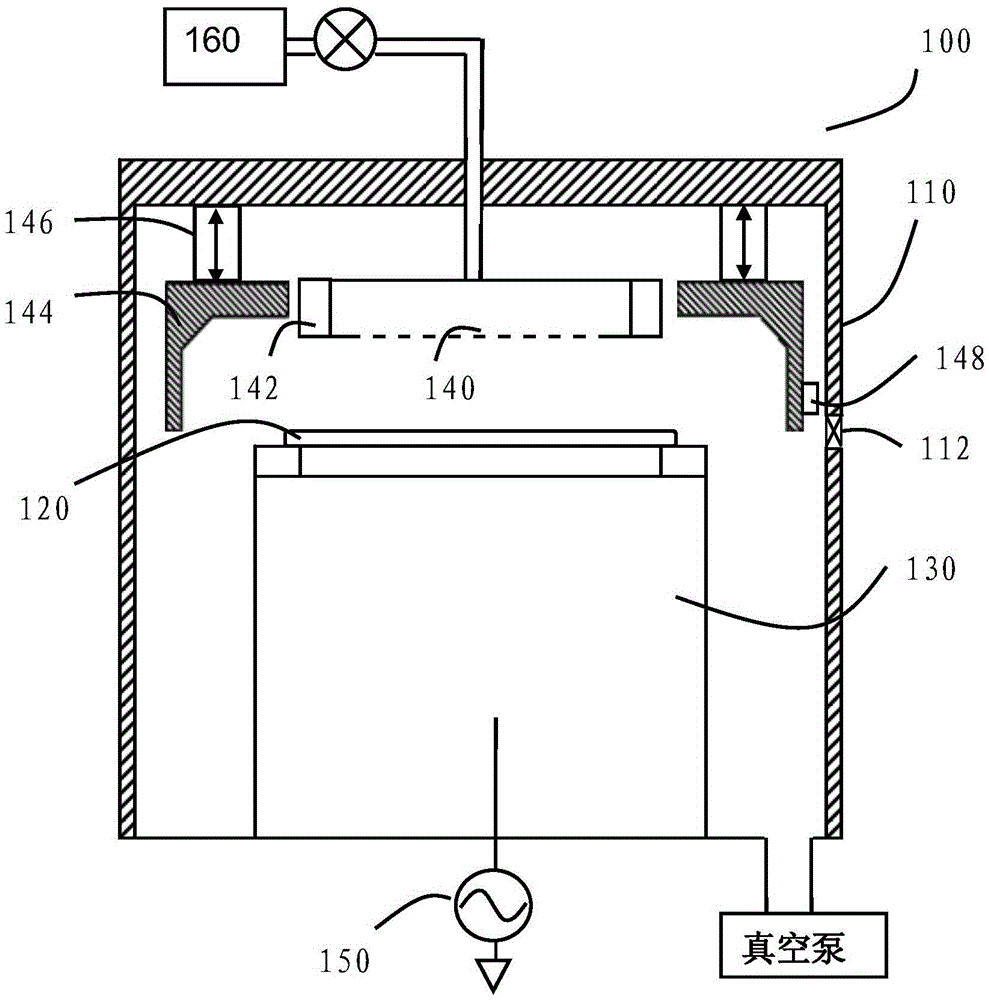

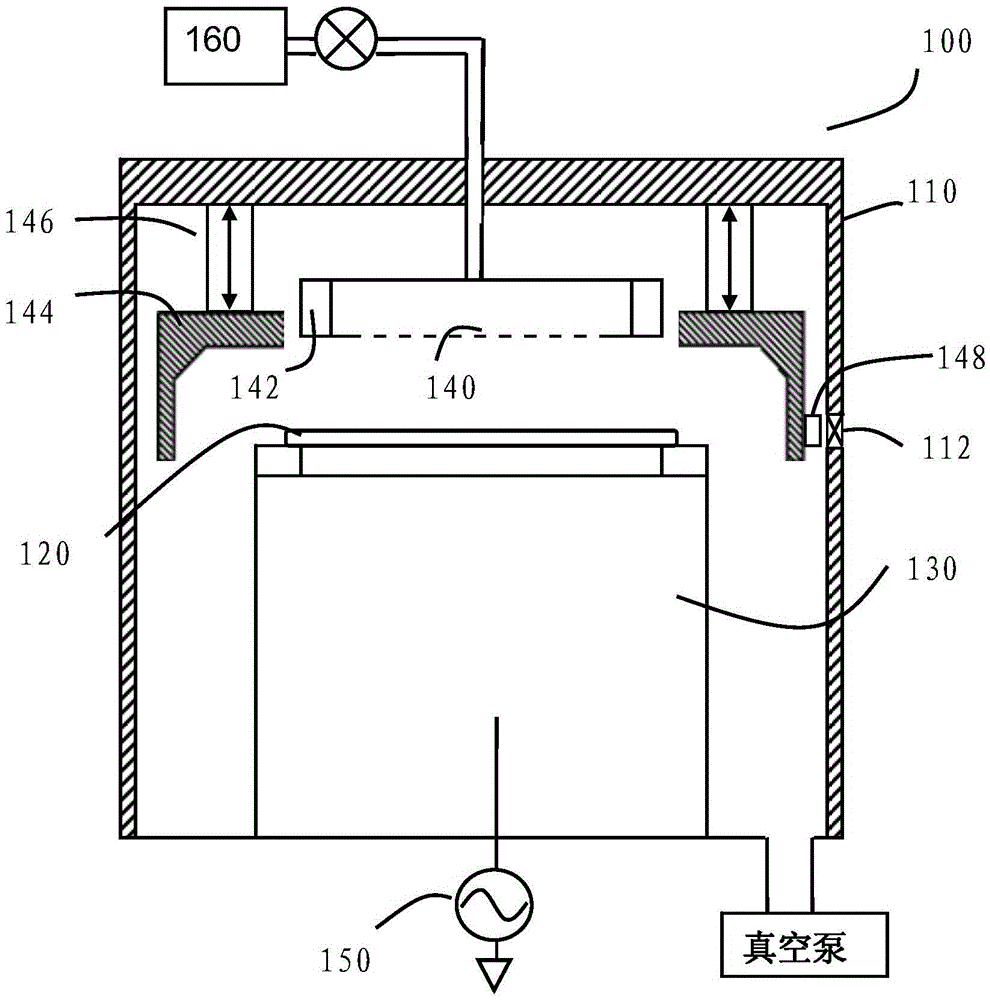

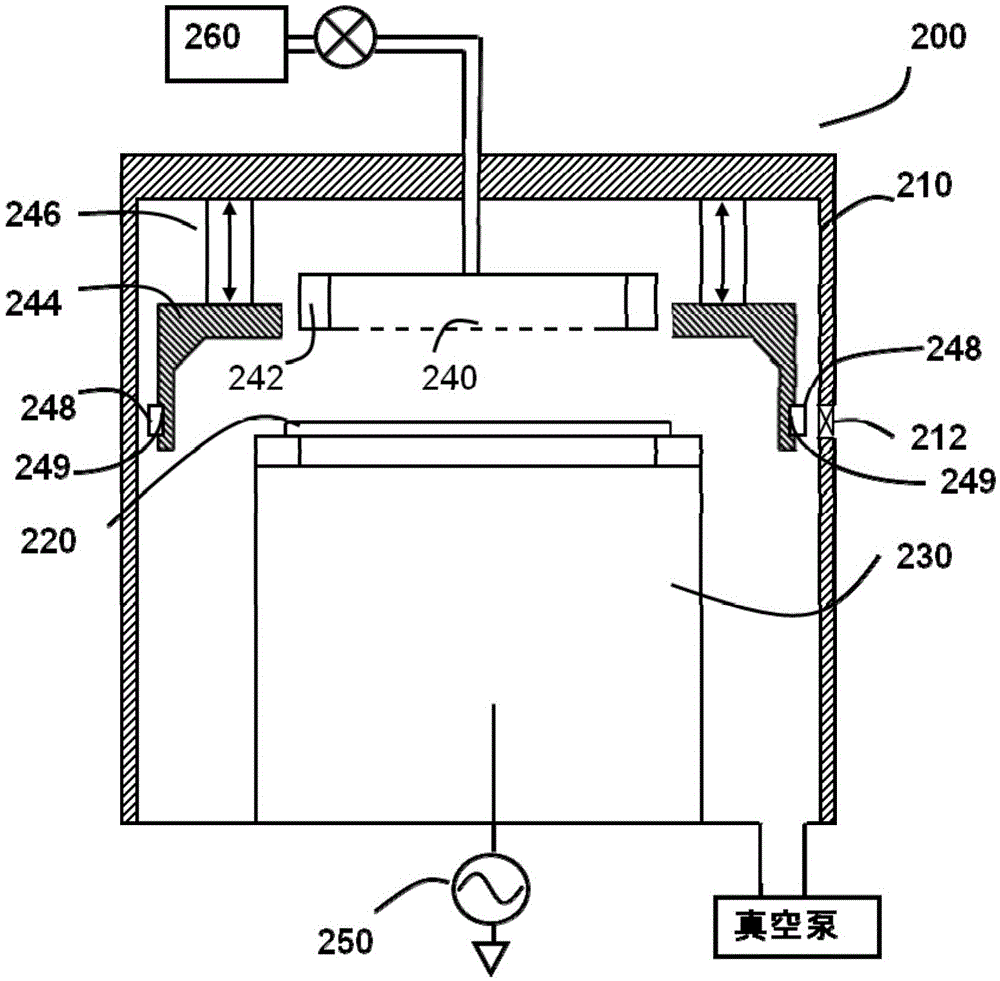

[0020] figure 1 A schematic structural view showing that the lifting ring of the plasma processing chamber of the present invention is in a raised state; figure 1 The shown plasma processing apparatus includes a vacuum processing chamber 100; the vacuum processing chamber 100 includes a cylindrical processing chamber side wall 110, and one side of the processing chamber side wall 110 is provided with a door that allows substrates to enter and exit Opening 112 . The upper electrode 140 and the lower electrode 130 opposite up and down are arranged in the vacuum processing chamber 100, and the lower electrode 130 is connected to the radio frequency power source 150, and simultaneously serves as a supporting device for the substrate 120; the upper electrode 140 is grounded, and is connected to the reaction gas source 160 simultaneously, as A gas shower head for supplying reactive gases into the processing chamber. A grounding ring 142 is arranged around the gas shower head 140 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com